Supporting structure assembly, transmission and vehicle

A supporting structure and transmission technology, applied in the field of vehicles, can solve the problems of grease pollution, inconvenient greasing and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

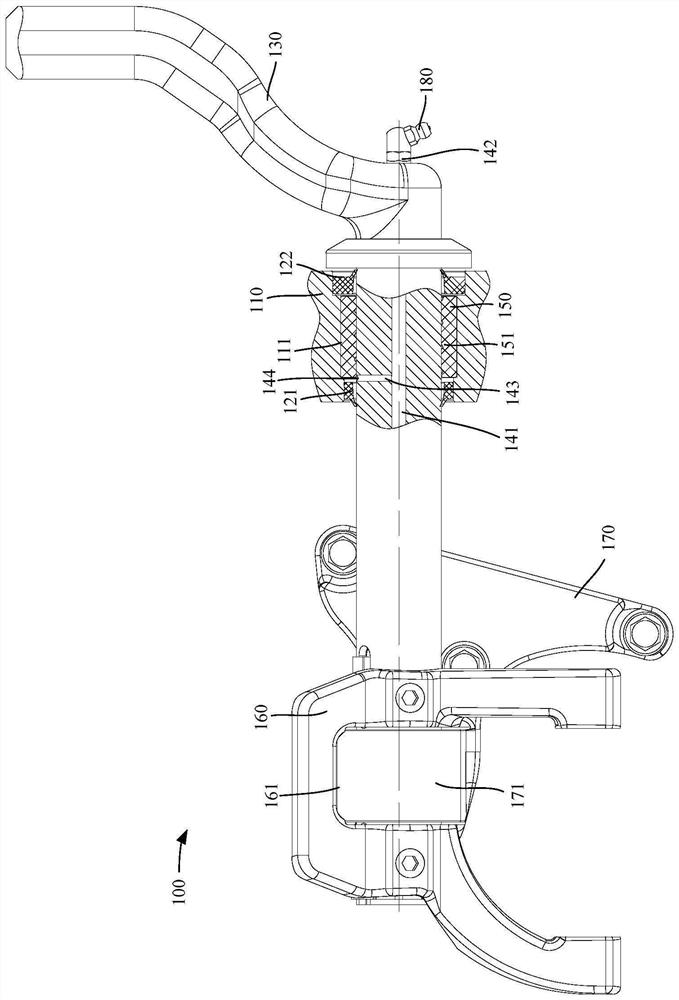

[0043] like figure 1 As shown, a support structure assembly 100 provided by an embodiment of the present invention includes a first housing 110 , a first sealing ring 121 , a second sealing ring 122 and a separation operation shaft 130 . Wherein, the first casing 110 is provided with a through hole 111 . The first sealing ring 121 is arranged at one end of the through hole 111 , and the second sealing ring 122 is arranged at the other end of the through hole 111 . Optionally, the first housing 110 is a clutch housing. Optionally, the first sealing ring 121 is an end face sealing rubber ring, and the second sealing ring 122 is an end face sealing rubber ring.

[0044] Further, the separation operation shaft 130 is penetrated through the first sealing ring 121 , the through hole 111 and the second sealing ring 122 . The two sealing rings are respectively located at both ends of the through hole 111 . Optionally, the first sealing ring 121 is an inner end sealing ring, and th...

Embodiment 2

[0049] like figure 1 As shown, the support structure assembly 100 also includes a bushing 150 . Specifically, the bushing 150 is disposed in the through hole 111 , and the bushing 150 is located between the first sealing ring 121 and the second sealing ring 122 . The separation operation shaft 130 is passed through the first sealing ring 121 , the bushing 150 and the second sealing ring 122 . The separation operation shaft 130 is rotatable relative to the first housing 110 . Further, the bushing 150 is provided with a grease storage tank 151 , and the oil passage communicates with the grease storage tank 151 . The external grease enters the oil passage through the first opening 142 , and then enters between the bushing 150 and the circumferential side wall of the separation operation shaft 130 through the second opening 144 , and a part of the grease is stored in the grease storage tank 151 . By arranging the grease storage tank 151, a part of the grease can be stored, whic...

Embodiment 3

[0053] like figure 1 As shown, the oil passages include axial oil passages 141 and radial oil passages 143 . Specifically, the axial oil passages 141 and the radial oil passages 143 communicate with each other. The first opening 142 is provided in the axial oil passage 141 , and the second opening 144 is provided in the radial oil passage 143 . The external grease enters the oil passage through the first opening 142, and then enters between the circumferential side wall of the separation operation shaft 130 and the inner wall of the through hole 111 through the second opening 144, so as to lubricate the separation operation shaft 130 and the through hole 111, It is beneficial to improve the reliability of separation.

[0054] In another embodiment, the support structure assembly 100 further includes a grease nipple 180 . Specifically, the grease nozzle 180 is provided at the first opening 142 , and the grease nozzle 180 can spray grease into the oil passage through the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com