PCB test fixture positioning pin and manufacturing method thereof

A technology for testing fixtures and PCB boards, which is applied in the direction of electronic circuit testing and measuring device casings, etc. It can solve the problems of low strength, short service life, and easy damage of positioning pins, and achieves increased anti-wear effects, simple manufacturing, and unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

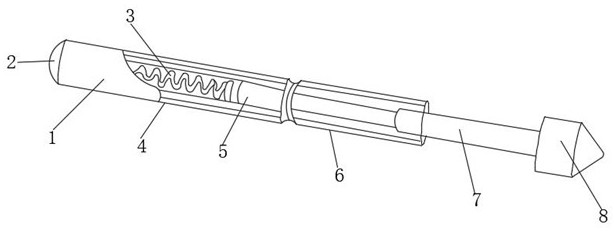

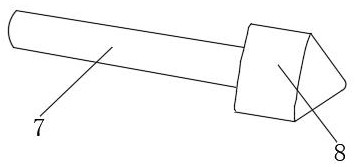

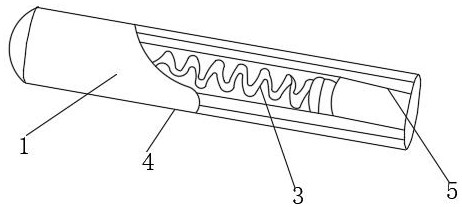

[0031] like Figure 1-4 As shown, a PCB board test fixture positioning needle includes a needle body 1, a needle holder 6 and a needle head 8. A needle tail 2 is arranged at the tail of the needle body 1, and a spring 3 is arranged inside the needle body 1. A piston 5 is installed at the end, a needle rod 7 is installed between the needle holder 6 and the needle head 8 , and a reinforcing shell 4 is installed on the outer wall of the needle body 1 .

[0032] Further, the reinforcing shell 4 includes a galvanized layer 9, a metal fiber layer 10, a polymer material layer 11, a copper alloy layer 12 and an aluminum alloy layer 13. The galvanized layer 9 is located on the outer surface of the metal fiber layer 10, and the metal fiber layer 10 It is located on the outer surface of the polymer material layer 11 , the polymer material layer 11 is located on the outer surface of the copper alloy layer 12 , and the copper alloy layer 12 is located on the outer surface of the aluminum a...

Embodiment 2

[0044] On the basis of Example 1, as Figure 1-4 As shown, a PCB board test fixture positioning needle includes a needle body 1, a needle holder 6 and a needle head 8. A needle tail 2 is arranged at the tail of the needle body 1, and a spring 3 is arranged inside the needle body 1. A piston 5 is installed at the end, a needle rod 7 is installed between the needle holder 6 and the needle head 8 , and a reinforcing shell 4 is installed on the outer wall of the needle body 1 .

[0045] Further, the reinforcing shell 4 includes a galvanized layer 9, a metal fiber layer 10, a polymer material layer 11, a copper alloy layer 12 and an aluminum alloy layer 13. The galvanized layer 9 is located on the outer surface of the metal fiber layer 10, and the metal fiber layer 10 It is located on the outer surface of the polymer material layer 11 , the polymer material layer 11 is located on the outer surface of the copper alloy layer 12 , and the copper alloy layer 12 is located on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com