Method for predicting steel billet temperature distribution in heating furnace based on particle swarm optimization algorithm

A technology of particle swarm optimization and temperature distribution, applied in heat treatment furnaces, design optimization/simulation, furnaces, etc., to solve damping and delay problems and reduce the number of iterations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

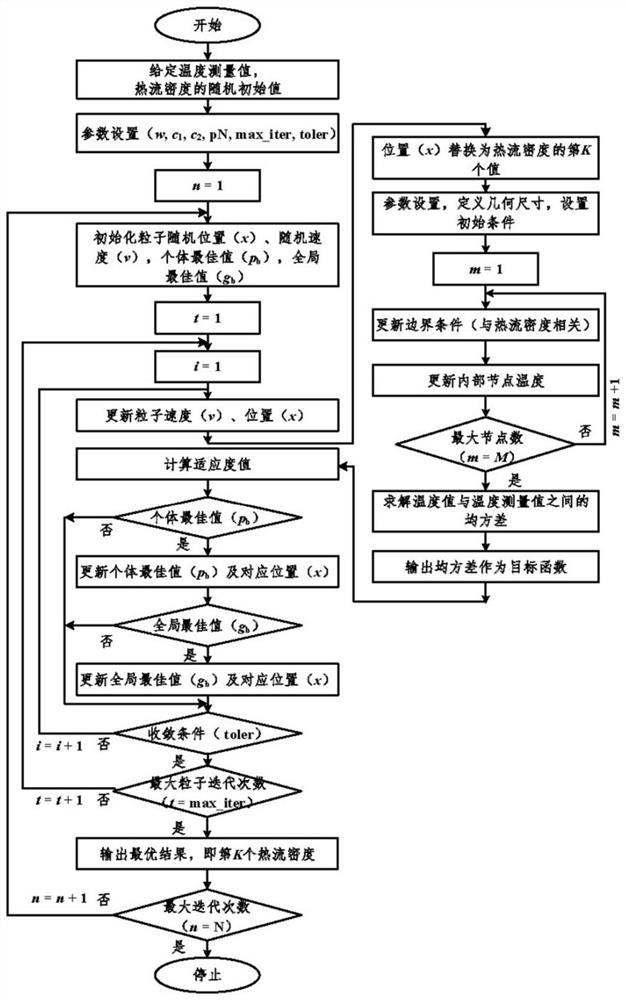

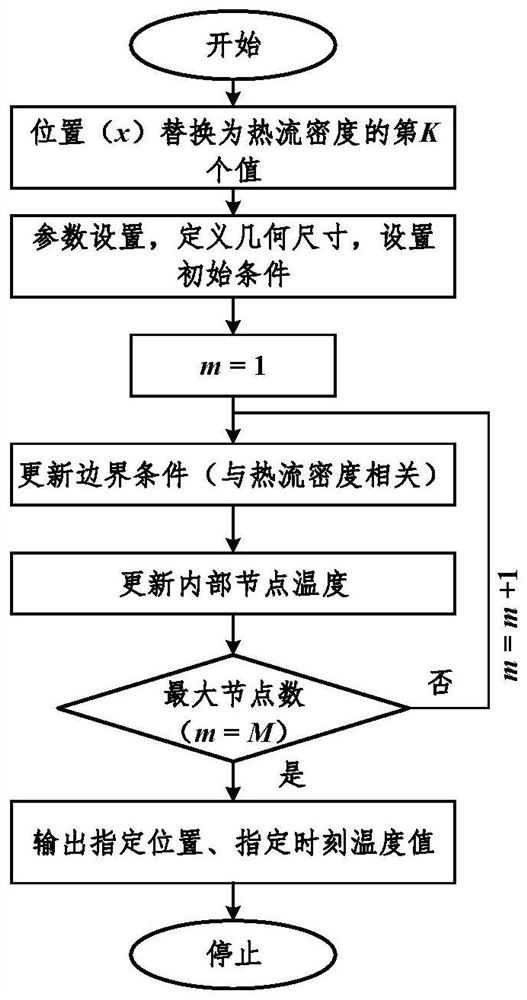

Method used

Image

Examples

Embodiment Construction

[0060] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

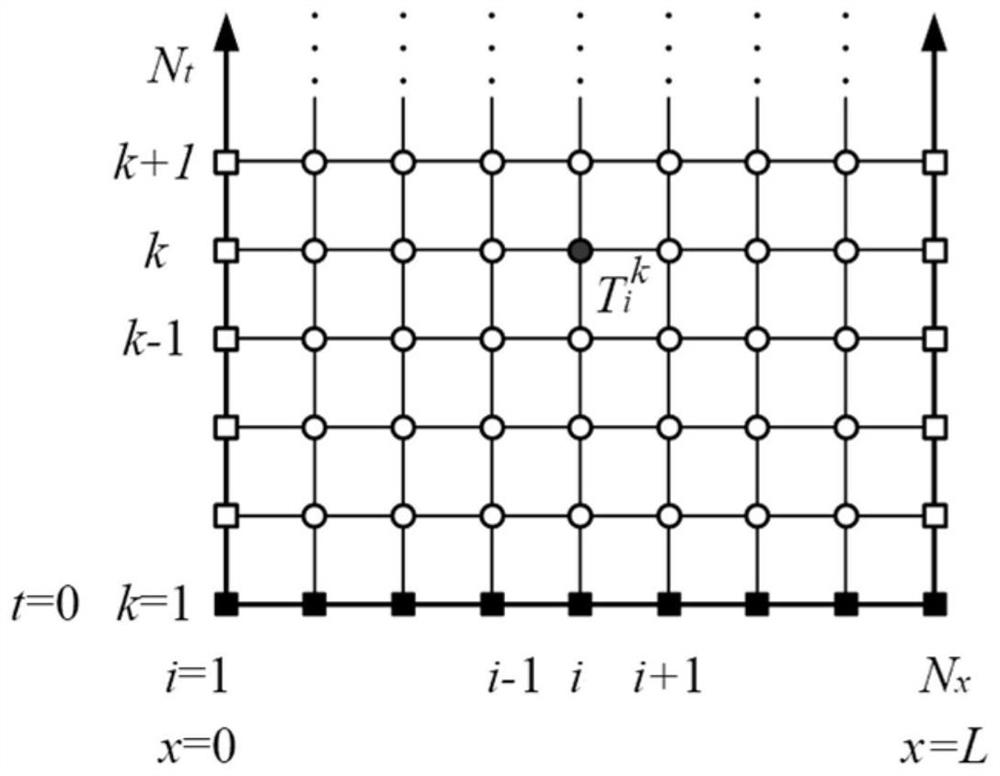

[0061] There are three types of boundary conditions in heat transfer, which are the basic elements for solving heat transfer problems, and each type of boundary conditions has its own special case. The first type of boundary condition is the formula for the temperature change of the given surface of the object; the second type of boundary condition is to give the relationship between the heat flux density and time on the surface of the object; the third type of boundary condition is to give the law of the temperature of the surrounding medium changing with time And the convective heat transfer coefficient between the surface of the object and the surrounding medium.

[0062] In the present invention, the second type of boundary conditions and the symmetric bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com