Epoxy pouring type current transformer and manufacturing method thereof

A current transformer, epoxy casting technology, applied in the manufacture of inductors/transformers/magnets, inductors, circuits, etc., can solve the problems of easy detachment, high production cost, poor packaging, etc., to achieve good conversion current and improve dynamic stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

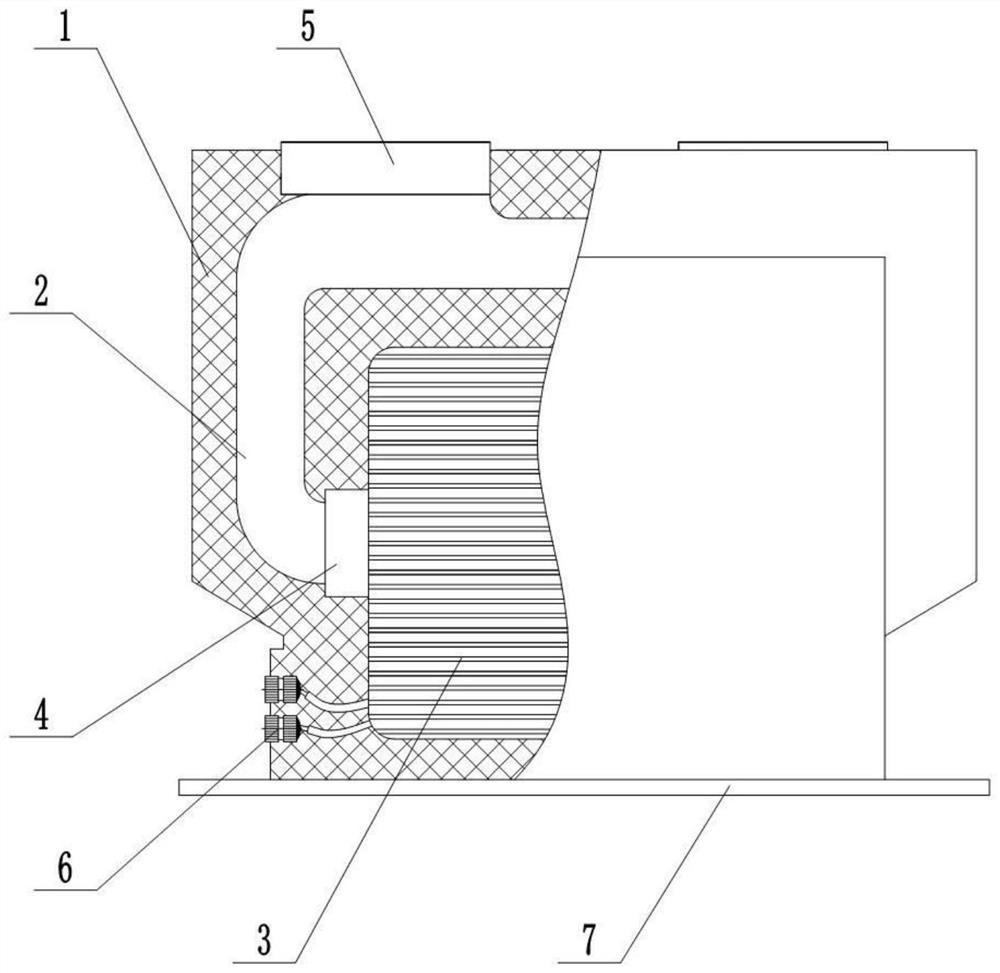

[0045] An epoxy casting type current transformer includes an epoxy resin body 1, a primary winding 2, and a secondary winding 3. The primary winding 2 includes a primary conductor 201 and an insulating layer wrapped on the primary conductor 201. The primary winding The lower side of 2 is concentrically sleeved with an insulating round tube 4, and the lower side and the insulating round tube 4 pass through the center hole of the secondary winding 3 concentrically, and the insulating round tube 4 is wrapped with a semi-conductive self-adhesive tape, and the primary winding 2. The top is provided with a primary terminal 5, the primary terminal 5 is connected to the primary winding 2, the primary terminal 5 protrudes from the top of the epoxy resin body 1, and the bottom of the epoxy resin body 1 is provided with a secondary terminal 6, so The secondary terminal 6 is connected to the secondary winding 3 through a wire. The secondary winding 3 includes an iron core and a secondary c...

Embodiment 2

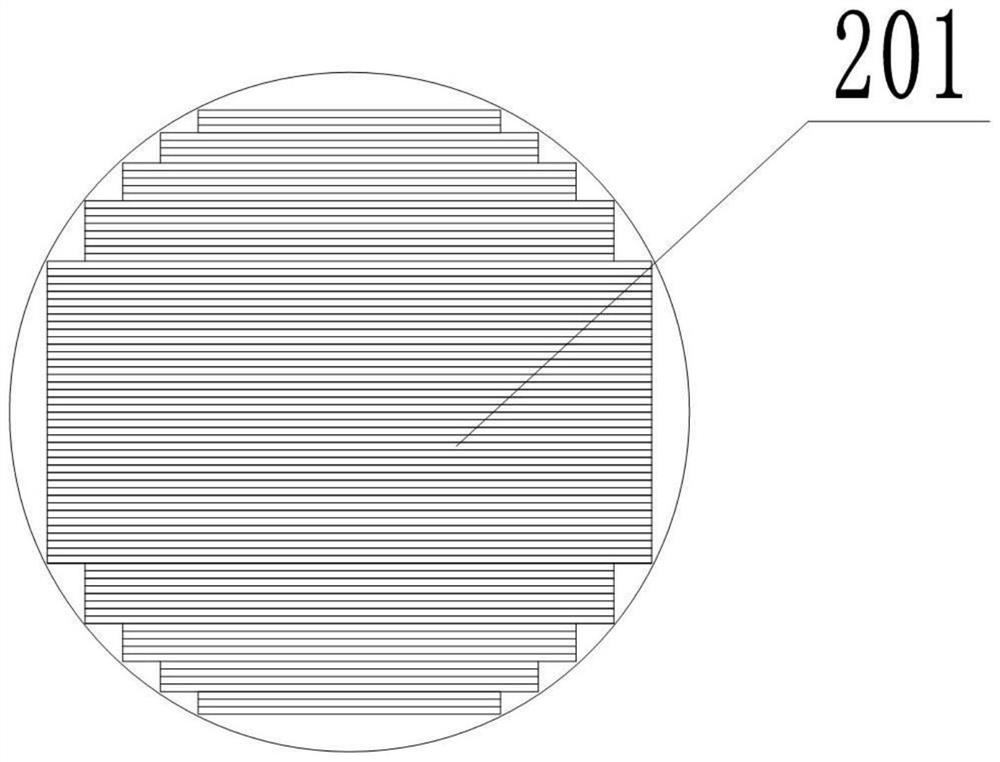

[0053] An epoxy casting type current transformer includes an epoxy resin body 1, a primary winding 2, and a secondary winding 3. The primary winding 2 includes a primary conductor 201 with a symmetrical stepped structure and an insulating layer wrapped on the primary conductor 201. , the lower side of the primary winding 2 is concentrically sleeved with an insulating round tube 4, and the lower side and the insulating round tube 4 pass through the center hole of the secondary winding 3 concentrically, and the insulating round tube 4 is wrapped with semi-conductive crepe paper, The top of the primary winding 2 is provided with a primary terminal 5, the primary terminal 5 is connected to the primary winding 2, the primary terminal 5 protrudes from the top of the epoxy resin body 1, and the bottom of the epoxy resin body 1 is provided with a secondary terminal. Terminal 6, the secondary terminal 6 is connected to the secondary winding 3 through a wire, the secondary winding 3 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com