Splicing tool and mounting method of permanent magnet alternating current servo motor magnetic steel

A technology of AC servo and installation method, applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of inconvenient, cumbersome and time-consuming installation of magnetic steel, affecting installation, etc., to achieve fast and convenient installation, improve installation convenience, and guarantee The effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

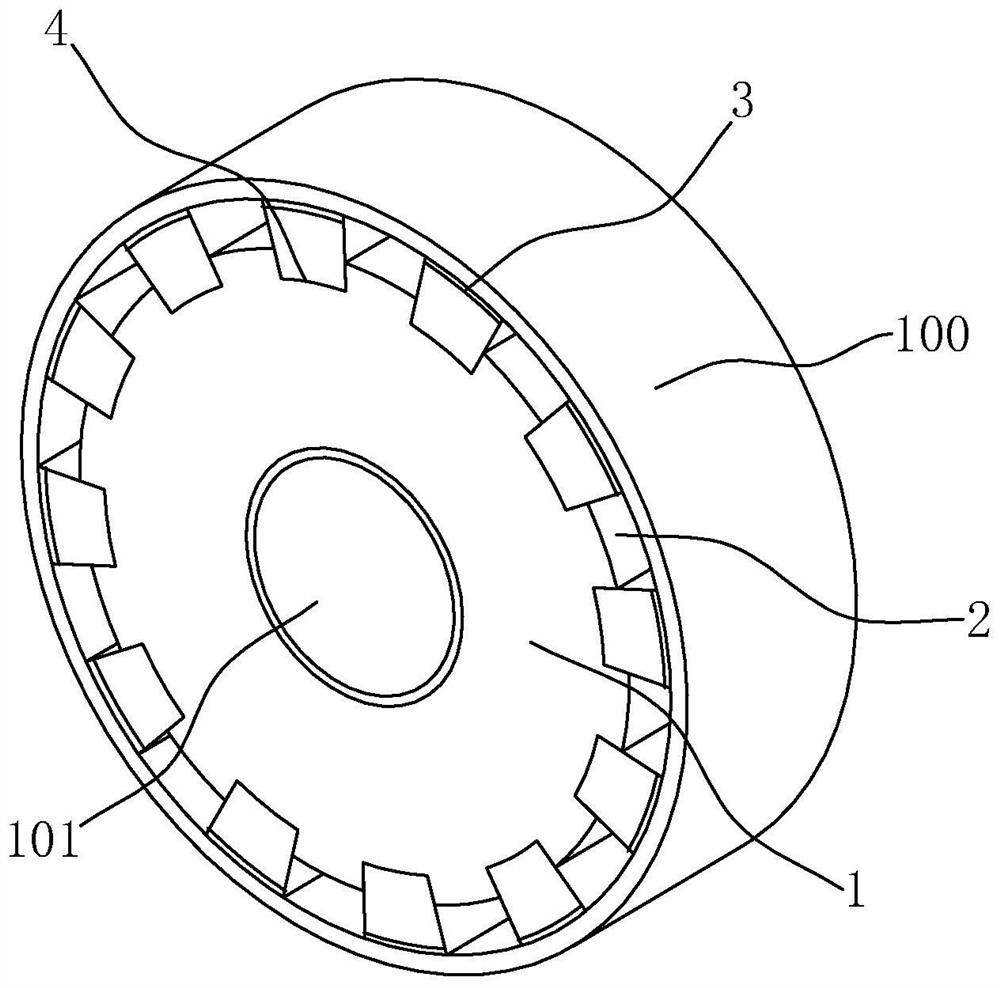

Embodiment 1

[0047] refer to image 3 , a splicing tool for permanent magnet AC servo motor magnetic steel, comprising a support 1, a number of limiters 2 and an adhesive layer 3, and a number of limiters 2 are arranged on the support 1 along the circumferential direction of the support 1, A receiving groove 4 is set between two adjacent limiting members 2 . During installation, the user places the support 1 in the rotor 100, makes the support 1 coaxial with the rotor 100, places the magnetic steel in the accommodating groove 4, and uses the adhesive layer 3 to glue the magnetic steel to the inner wall of the rotor 100. Then the user takes out the support 1 and the limiter 2 from the rotor 100, places the residual magnetic steel in the position where the limiter 2 is not taken out of the rotor 100, and uses the adhesive layer 3 to fix it to complete the installation .

[0048] refer to image 3, the support 1 is in the shape of a cylinder with an outer diameter smaller than the inner di...

Embodiment 2

[0057] refer to Figure 4 , the main difference between this embodiment and Embodiment 1 is that a connecting member 5 is installed on one side of the support member 1, and the connecting member 5 is in the shape of a circular plate. When the user places the support member 1 in the rotor 100, the connecting member 5 is connected The part 5 is located on the side of the support part 1 away from the rotor 100. The edge of the connecting part 5 is provided with an avoidance groove 51 corresponding to the accommodating groove 4. The shape of the escape groove 51 is the same as that of the accommodating groove 4. Insert into the accommodating groove 4 through the escape groove 51 .

[0058] refer to Figure 4 and Figure 5 , all the limiting members 2 are slidably connected to the supporting member 1 on one side close to the supporting member 1, and are fixedly connected to the connecting member 5 at one end close to the connecting member 5. When all the magnetic steels are inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com