Feed fermentation device for aquaculture

A fermentation device and aquaculture technology, applied in the field of fermentation equipment, can solve problems such as uneven fermentation degree, and achieve the effect of saving labor in the operation process and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

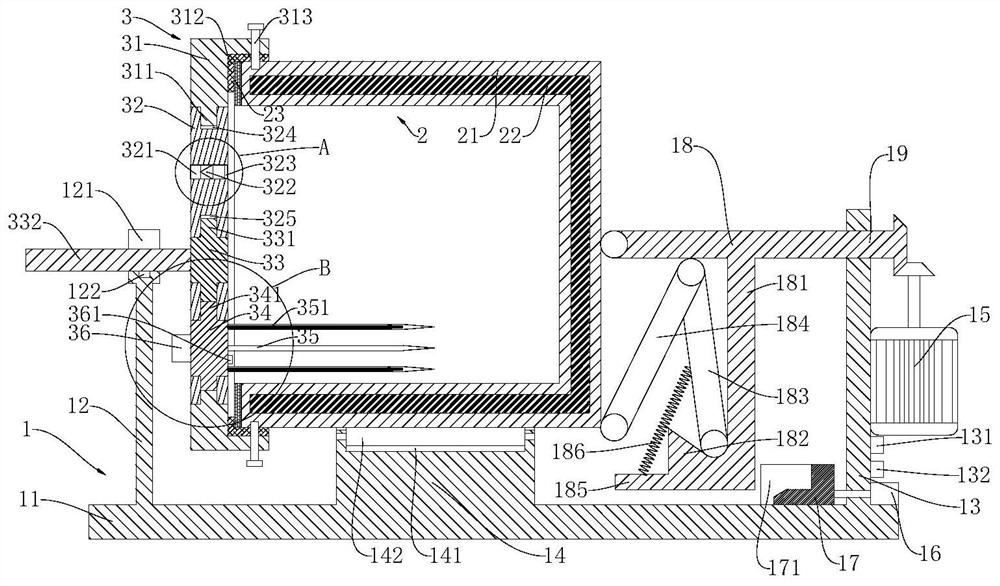

[0037] Such as Figure 1 to Figure 3 and Figure 7 As shown, a feed fermentation device for aquaculture provided by the embodiment of the present invention includes a frame 1, a cylinder body 2 and a cover body 3, wherein:

[0038] Frame 1 comprises base 11, support column 12, first vertical plate 13, support platform 14, servo motor 15 and transmission rod 19, and support column 12 and first vertical plate 13 are vertically fixedly connected to base 11 respectively, and first vertical plate 13 is fixedly connected with a second button 131, the first vertical plate 13 is also provided with a controller 132, the second button 131 is connected with the signal of the controller 132, the controller 132 is connected with the signal of the servo motor 15, and is used to control the servo motor 15 Start and stop, the servo motor 15 is fixedly connected to one side of the first vertical plate 13, the transmission rod 19 is rotatably connected to the first vertical plate 13, one end of ...

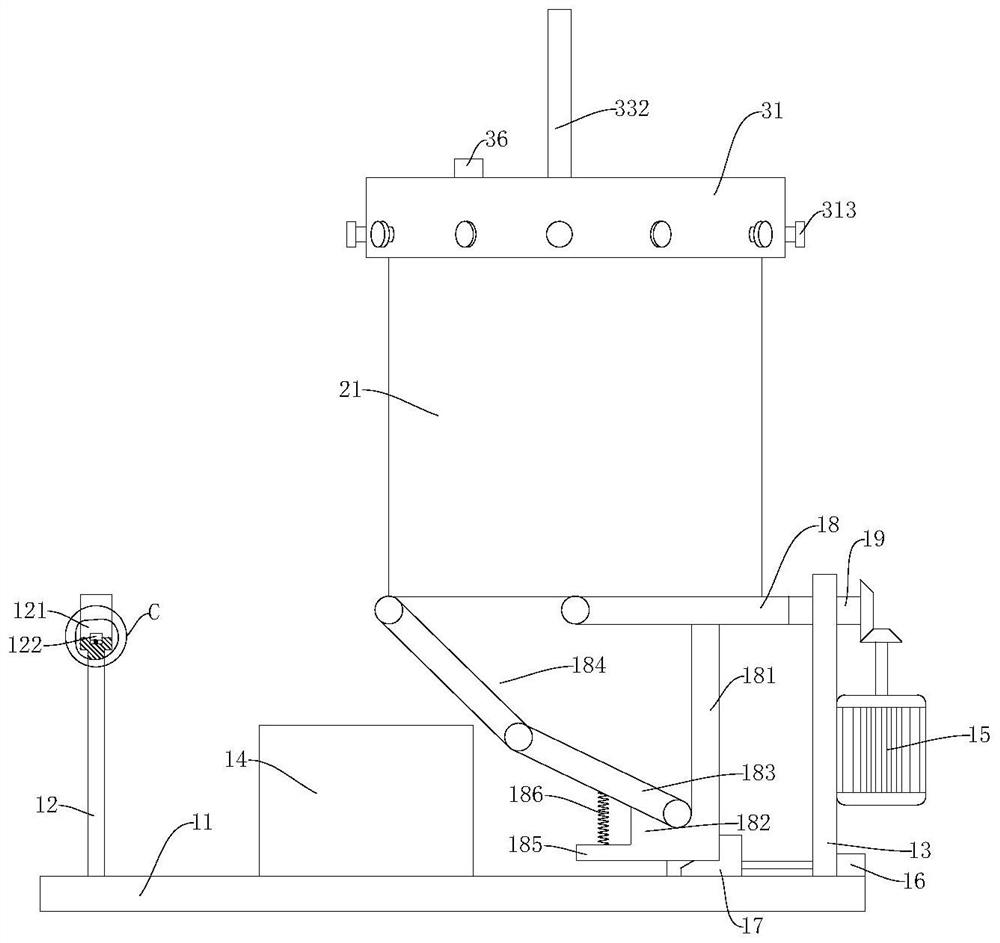

specific Embodiment 2

[0045] In Embodiment 1, due to only relying on the braking of the servo motor 15 to adjust the cylinder 2 to the first working state, the cylinder 2 is not stable enough and there is a danger of tipping over. Therefore, on the basis of Embodiment 2, as Figure 1 to Figure 3 , Figure 5 , Figure 7 , Figure 9 As shown, the frame 1 in this embodiment also includes an electric push rod 16, a support block 17 and a support platform 18, and the support platform 18 is fixedly connected to the transmission rod 19, so that when the cylinder 2 is in the first working state, the cylinder 2 The bottom of the bottom can be stably placed on the support platform 18, the lower end of the support platform 18 is fixedly connected with a second vertical plate 181, one end of the first hinged rod 183 is hinged on the second vertical plate 181, and the other end of the first hinged rod 183 is hinged To one end of the second hinged rod 184, the other end of the second hinged rod 184 is hinged t...

specific Embodiment 3

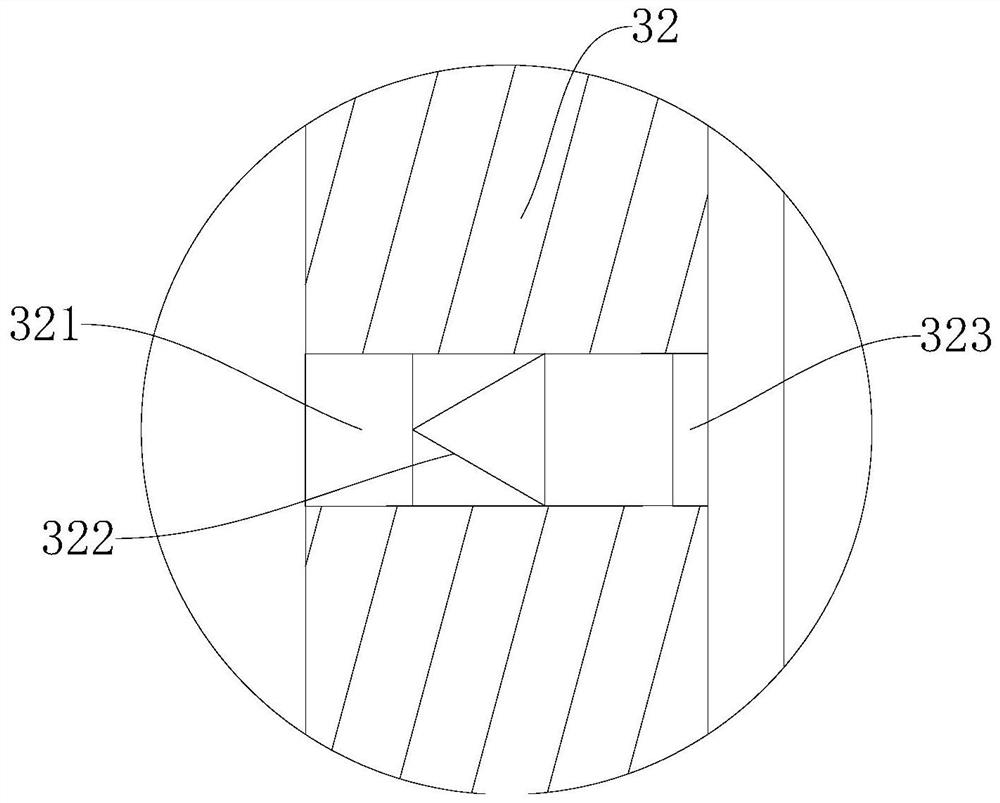

[0052] In embodiment 1 or embodiment 2, since the feed at the center of cylinder body 2 and the feed fermentation conditions at the side wall of cylinder body 2 still have certain differences during fermentation, in order to improve the consistency of the fermentation degree of feed, therefore, in the implementation Based on Example 3, such as Figure 1 to Figure 8 As shown, in the present embodiment, the cover body 3 includes a bucket cover outer ring 31, a sealing plate 32, a sun plate 33, a planetary plate 34 and a stirring rod 35, and the inner ring side of the cover outer ring 31 is provided with a first flange 311, the second A flange 311 is provided with a first gear tooth, the sealing plate 32 is annular, the inner ring side of the sealing plate 32 is provided with a first sliding groove 324, and the outer ring side of the sealing plate 32 is provided with a second sliding groove 325 , the first flange 311 is slidably connected to the first sliding groove 324, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com