Heater for aerosol-forming substrate comprising positive temperature coefficient thermistor

A thermistor, aerosol generation technology, applied in the direction of ohmic resistance heating, ohmic resistance heating circuit diagram, thermometer, etc., can solve the problems of slow thermal response of resistance heating elements, difficult to avoid potential overheating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

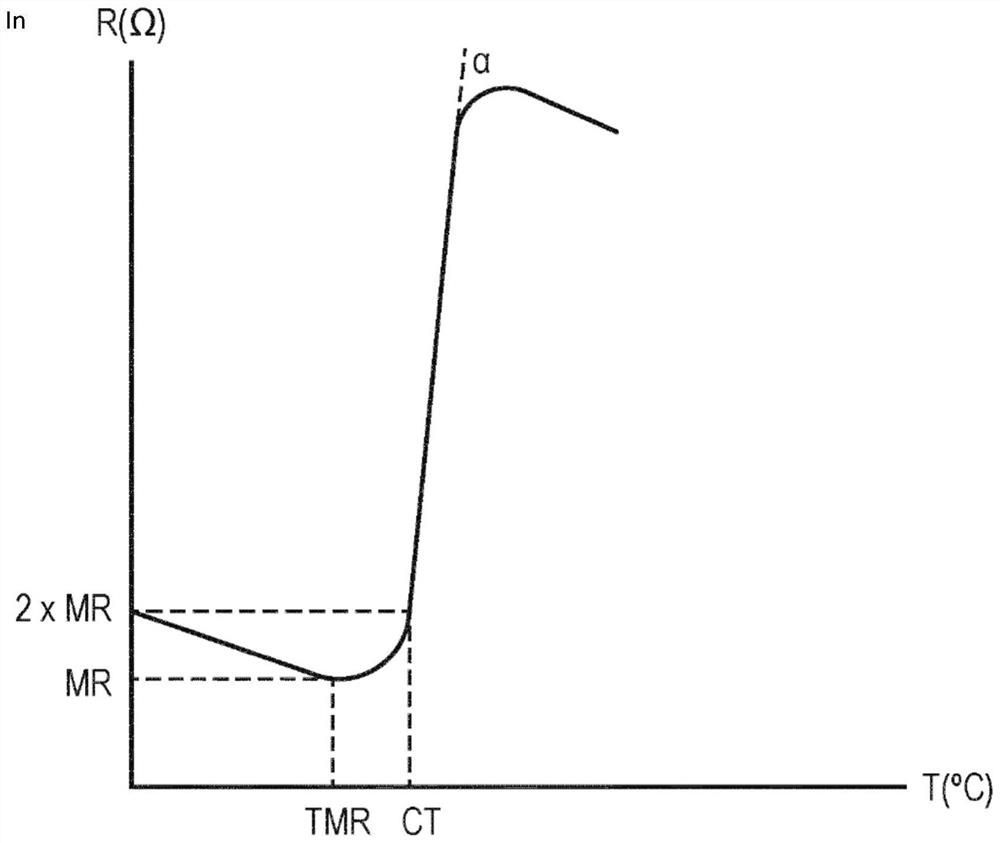

[0132] figure 1 The temperature T / resistance R graph of a PTC thermistor included in the heating element of the heater for heating the aerosol-forming substrate is shown.

[0133] When current is supplied to the PTC thermistor, the PTC thermistor is heated. When heating the PTC thermistor, the temperature T and resistance R of the PTC thermistor are based on figure 1 function shown in .

[0134] In particular, the PTC thermistor can be heated to a temperature TMR corresponding to the minimum resistance MR of the PTC thermistor.

[0135] When the PTC thermistor is heated to a temperature T lower than the temperature corresponding to the minimum resistance TMR, the resistance R of the PTC thermistor is based on figure 1 A function of decreases slightly as the temperature T of the PTC thermistor increases. In some PTC thermistors, the resistance R of the PTC thermistor remains substantially constant, at a resistance slightly higher than the minimum resistance MR of the PTC th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com