Multi-anti-counterfeiting method and multi-anti-counterfeiting element based on structural color

An anti-counterfeiting element and structural color technology, applied in the field of anti-counterfeiting, can solve the problems of easy imitation of the anti-counterfeiting method and low encryption degree, and achieve the effects of increasing the difficulty of imitation, improving the encryption degree and high resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

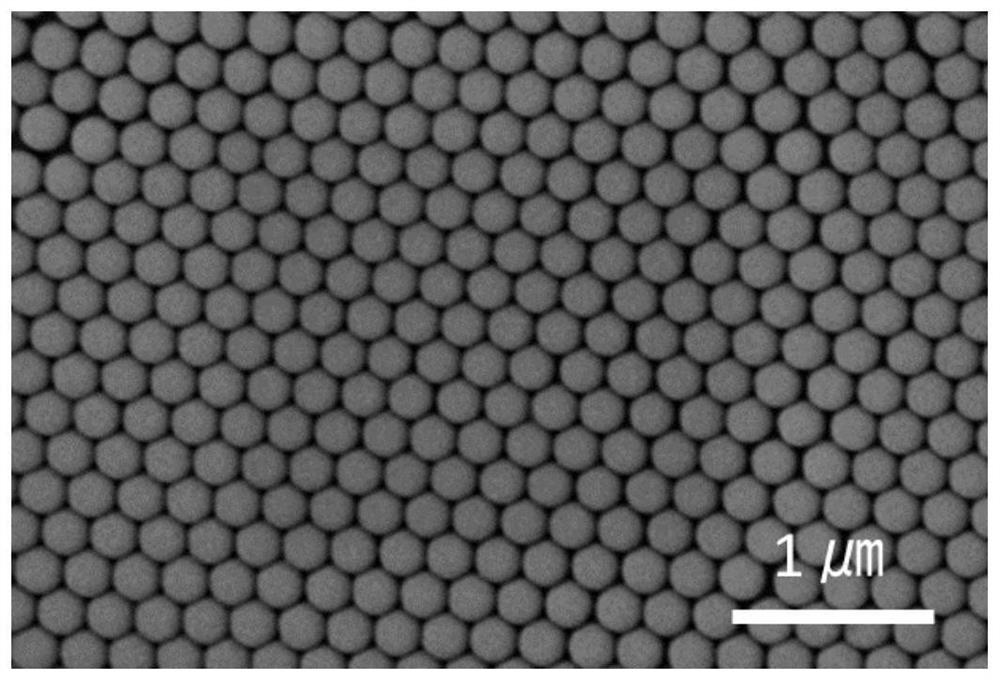

[0099] (1) Preparation of colloidal microsphere dispersion: 156 nm monodisperse poly(styrene-methacrylic acid) colloidal microspheres and 240 nm monodisperse porous silica colloidal microspheres were dispersed in deionized water, and then placed in a frequency Disperse in a 120Hz ultrasonic disperser for 10min. The porous silica colloidal microsphere dispersion liquid with a concentration of 3% (by mass fraction) and a poly(styrene-methacrylic acid) colloidal microsphere dispersion liquid with a concentration of 10% (by mass fraction) were prepared respectively. .

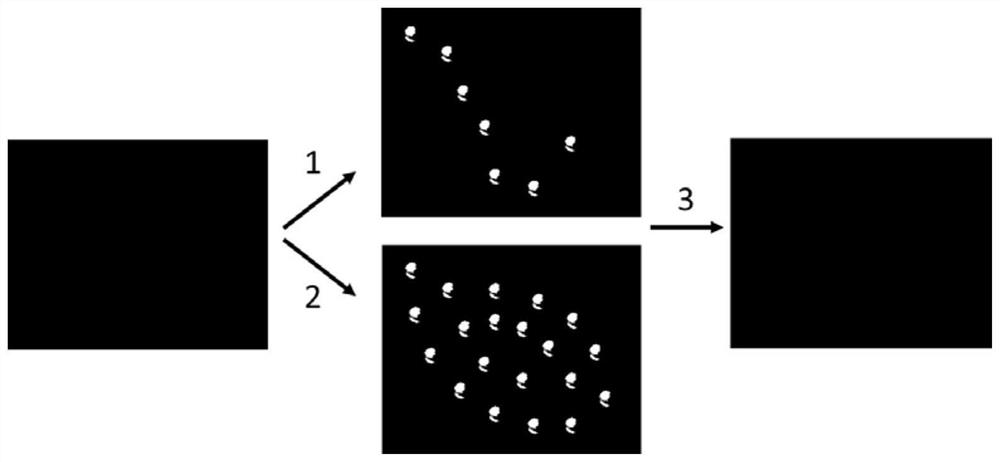

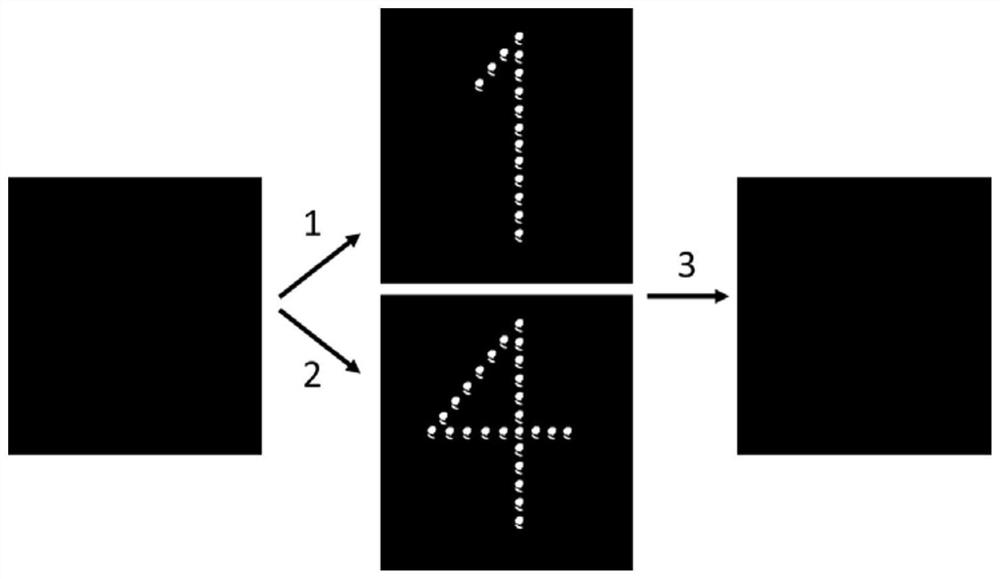

[0100] (2) The monodisperse poly(styrene-methacrylic acid) colloidal microsphere dispersion is uniformly spray-printed on the polyester fabric within the design range of the first preset pattern by an ink-jet printer, and the polyester fabric is placed at 60° after the spray-printing. Perform drying treatment in an oven at a temperature of Within the design range of the second preset pattern, after spray printing...

Embodiment 2

[0104] (1) Preparation of colloidal microsphere dispersion: 154 nm monodisperse polystyrene colloidal microspheres and 239 nm monodisperse porous silica colloidal microspheres were dispersed in deionized water, and then placed in an ultrasonic disperser with a frequency of 120 Hz Disperse for 10min. The porous silica colloidal microsphere dispersion liquid with a concentration of 3% (by mass fraction) and a poly(styrene-methacrylic acid) colloidal microsphere dispersion liquid with a concentration of 10% (by mass fraction) were prepared respectively. .

[0105] (2) The monodisperse polystyrene colloidal microsphere dispersion liquid is uniformly spray-printed on the paper within the design range of the first preset pattern by an ink-jet printer, and the paper is placed in an oven at 60°C for drying treatment after spray-printing , forming a first photonic crystal, that is, forming a first preset pattern that is invisible under visible light irradiation; then uniformly spray-p...

Embodiment 3

[0109] (1) Preparation of colloidal microsphere dispersion: 156 nm monodisperse poly(styrene-butyl acrylate-methacrylic acid) colloidal microspheres and 240 nm monodisperse porous silica colloidal microspheres were dispersed in deionized water, Afterwards, it was placed in an ultrasonic disperser with a frequency of 120 Hz to disperse for 10 min. The porous silica colloidal microsphere dispersion liquid with a concentration of 3% (by mass fraction) and a poly(styrene-methacrylic acid) colloidal microsphere dispersion liquid with a concentration of 10% (by mass fraction) were prepared respectively. .

[0110] (2) The monodisperse poly(styrene-butyl acrylate-methacrylic acid) colloidal microsphere dispersion is uniformly spray-printed on the polyester fabric within the design range of the first preset pattern by an ink-jet printer. The fabric is dried in an oven at 60°C to form a first photonic crystal, that is, a first preset pattern that is invisible under visible light irrad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com