Method for preparing ceramic handicraft by utilizing dried sludge

A technology of ceramic handicrafts and dried sludge, which is applied in the production and application of clay products and ceramic materials, can solve the problems of complex preparation process, poor performance of ceramic products, high cost, etc., and achieve low glass transition temperature, simple composition, high The effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

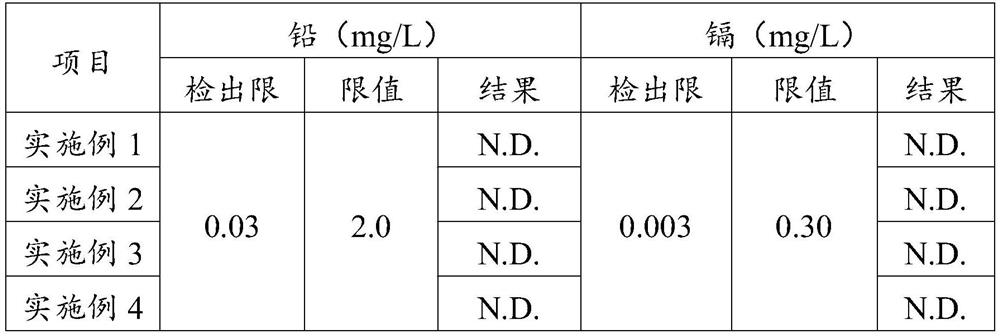

Examples

Embodiment 1

[0040] The present embodiment provides a method for preparing a ceramic flowerpot by using dried sludge, comprising the following steps:

[0041] The dried sludge of the municipal sewage plant with a moisture content of 38% was heat-treated at 400°C for 60 minutes, then pulverized to 100 mesh, and then the dried sludge was mixed with clay (particle size of 100 mesh) in a mass ratio of 70:30, and water was added. The mud sticks with a moisture content of 25% are obtained; the mud sticks are drilled for 5 minutes with a mud mixer, and the air bubbles in the mud are discharged; then the mud blocks after mud training are put into the mold, and the mud blocks are pressed at 4 MPa for 1 min by a hydraulic device , and air-dried at room temperature for 12 hours after pressing to obtain a clay embryo; the clay embryo was glazed and fired at 950° C. for 60 minutes, and taken out when the temperature dropped to room temperature to obtain a ceramic flower pot.

[0042] The actual picture...

Embodiment 2

[0044] The present embodiment provides a method for preparing a ceramic flowerpot by using dried sludge, comprising the following steps:

[0045]The dried sludge of the municipal sewage plant with a moisture content of 39% was heat-treated at 410 ° C for 45 minutes, then pulverized to 200 mesh, and then the dried sludge was mixed with clay (particle size of 200 mesh) according to the mass ratio of 65:35, and water was added. The mud sticks with a moisture content of 29% were obtained; the mud sticks were drilled for 6 minutes with a mud mixer, and the air bubbles in the mud were discharged; then the mud blocks after mud training were put into the mold, and the mud blocks were pressed at 6MPa for 2 minutes by a hydraulic device , and air-dried at room temperature for 18 hours after pressing to obtain a clay embryo; the clay embryo was glazed and fired at 900° C. for 50 minutes, and taken out when the temperature dropped to room temperature to obtain a ceramic flowerpot.

[0046...

Embodiment 3

[0048] The present embodiment provides a method for preparing a ceramic flowerpot by utilizing dried sludge, comprising the following steps:

[0049] The dried sludge of the municipal sewage plant with a moisture content of 35% was heat-treated at 370 ° C for 40 minutes, then pulverized to 150 mesh, and then the dried sludge was mixed with clay (particle size of 150 mesh) according to the mass ratio of 75:25, and water was added. The mud sticks with a moisture content of 34% are obtained; the mud sticks are drilled for 10 minutes with a mud mixer, and the air bubbles in the mud are discharged; then the mud blocks after mud training are put into the mold, and the mud blocks are pressed at 9 MPa for 1 min by a hydraulic device , and air-dried at room temperature for 24 hours after pressing to obtain a clay embryo; the clay embryo was glazed and fired at 850° C. for 50 minutes, and taken out when the temperature dropped to room temperature to obtain a ceramic flower pot.

[0050]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com