Method capable of improving whole rod rate of heavily phosphorus-doped low resistor

A low-resistance, whole-rod rate technology, applied in chemical instruments and methods, self-molten liquid pulling method, final product manufacturing, etc., can solve the problems of compositional supercooling, low whole rod rate, affecting the normal growth of single crystals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to illustrate the technical solutions of the embodiments of the present invention more clearly, the following will briefly introduce the accompanying drawings used in the embodiments. Obviously, the drawings in the following description are some embodiments of the present invention, which are of great significance to the art For those of ordinary skill, other drawings can also be obtained from these drawings without any creative effort.

[0030] A method capable of improving the overall rod rate of heavily doped phosphorus and low resistance, comprising the steps of:

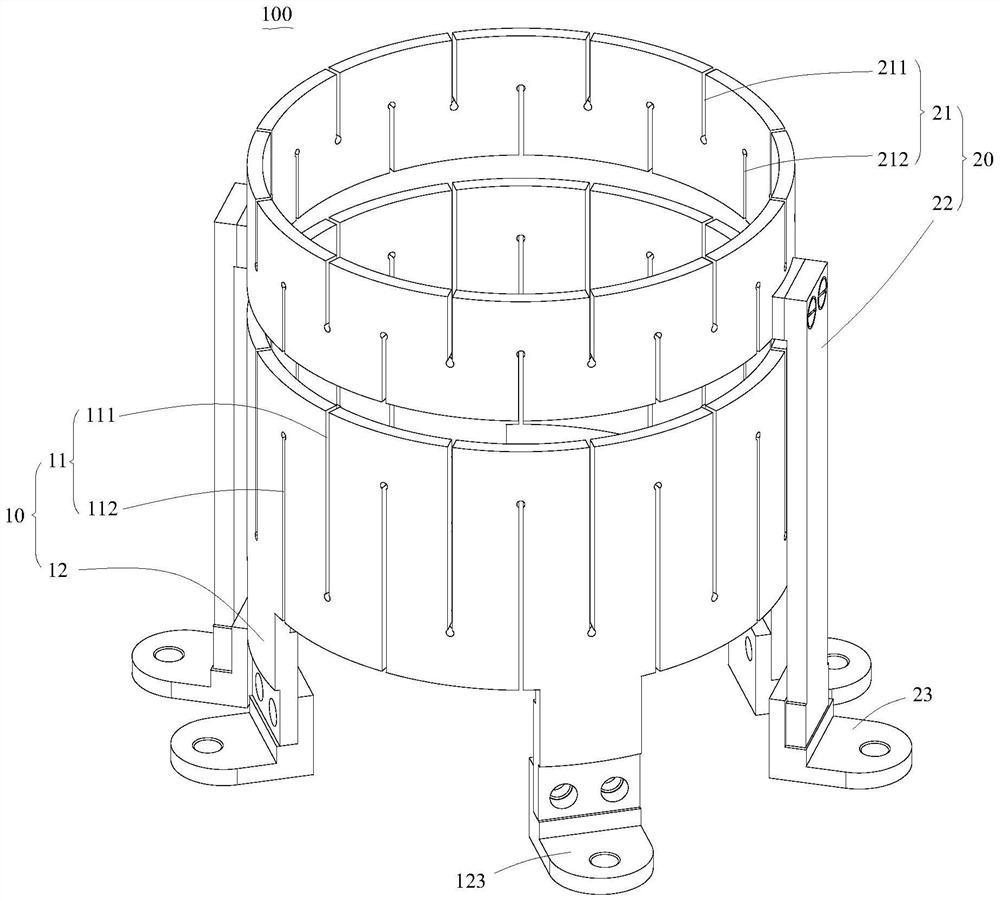

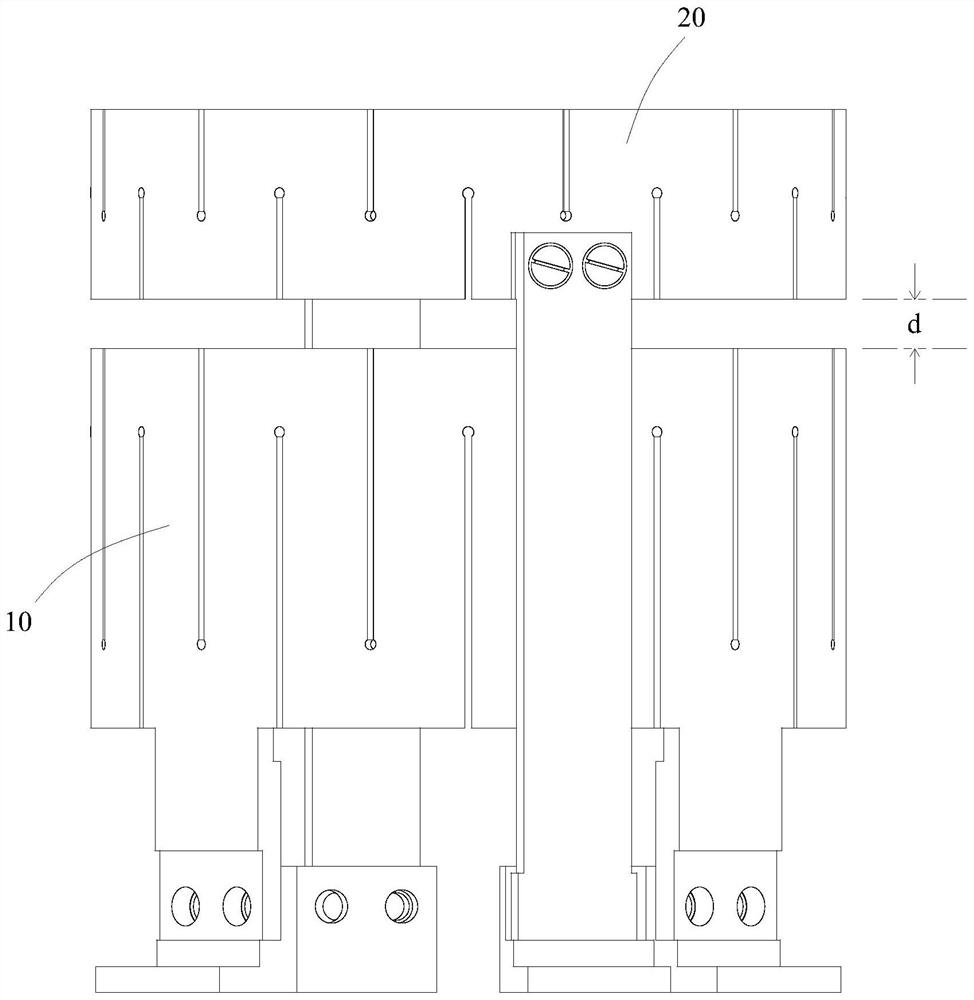

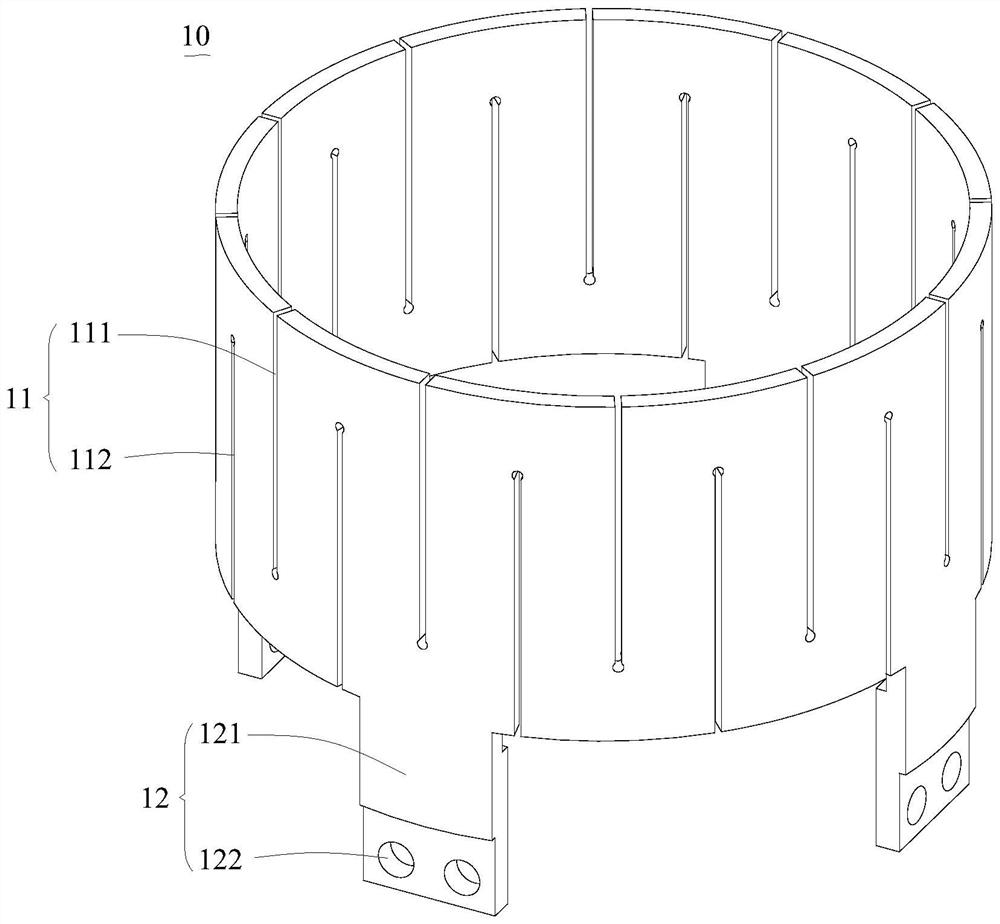

[0031] Split side heaters available: see Figure 1 to Figure 6 , the split side heater 100 includes a main heater 10 and an auxiliary heater 20, the main heater 10 and the auxiliary heater 20 are both cylindrical structures with openings at both ends, and both the main heater 10 and the auxiliary heater 20 include On the opposite top open end and bottom open end, the auxiliary heater 20 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com