Control method of fuel cell air compressor

A control method and fuel cell technology, applied in fuel cells, pump control, circuits, etc., can solve the problems of data reduction affecting accuracy, limited control accuracy, insufficient finesse, etc., to achieve accurate air flow, meet response requirements, and reduce energy. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below with reference to the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

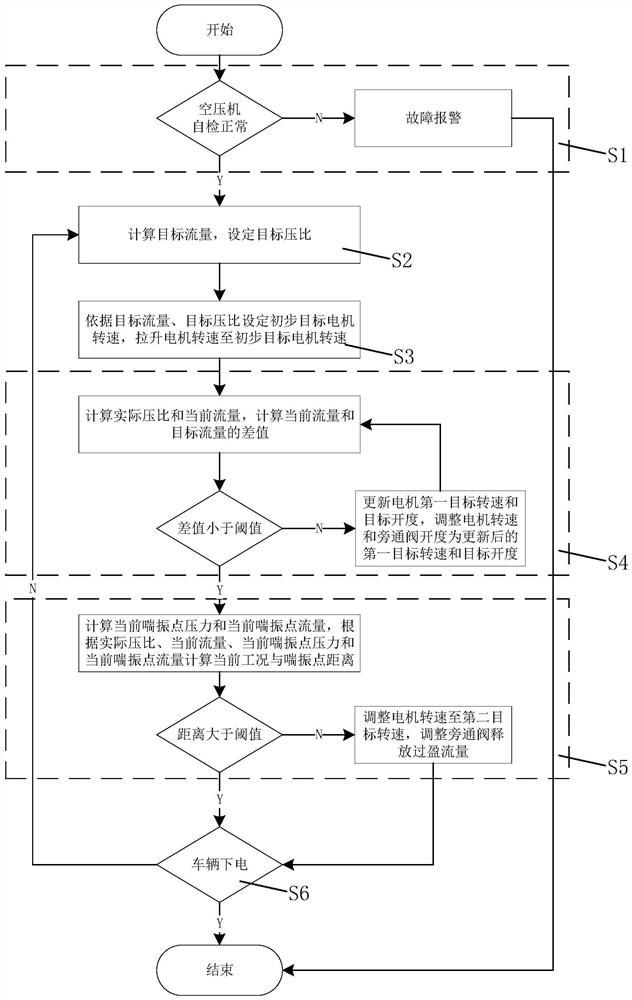

[0054] like figure 1 As shown, this embodiment provides a control method for a fuel cell air compressor, which includes the following steps:

[0055] S1) After the vehicle is powered on, perform a self-check of the air compressor, and execute step S2) if the self-check is passed, otherwise an abnormal alarm will be issued, and then enter the fault mode, and the fuel cell is prohibited from working in the fault mode;

[0056] S2) Calculate the required power P_FC_Demand according to the accelerator pedal depth and the working condition of the fuel cell, and calculate the target flow Air_Q_Demand and the target pressure ratio Ratio_P_Demand according to the required power P_FC_Demand;

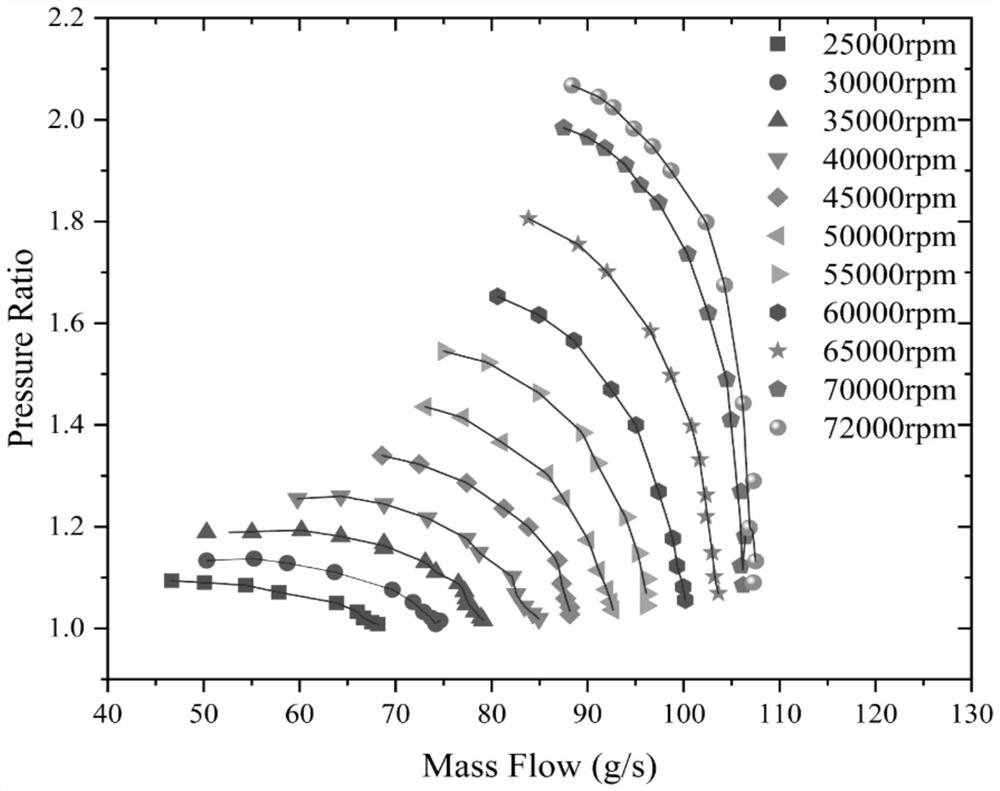

[0057] S3) Match the preset table Map_Cp_Speed_pre with the target flow Air_Q_D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com