Automatic air leakage device and automatic air leakage method for full-area temperature sensing of bottle body

An all-area, automatic technology, applied in the container discharge method, container filling method, gas/liquid distribution and storage, etc., can solve the problems of inability to relieve pressure, large induction blind zone, explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

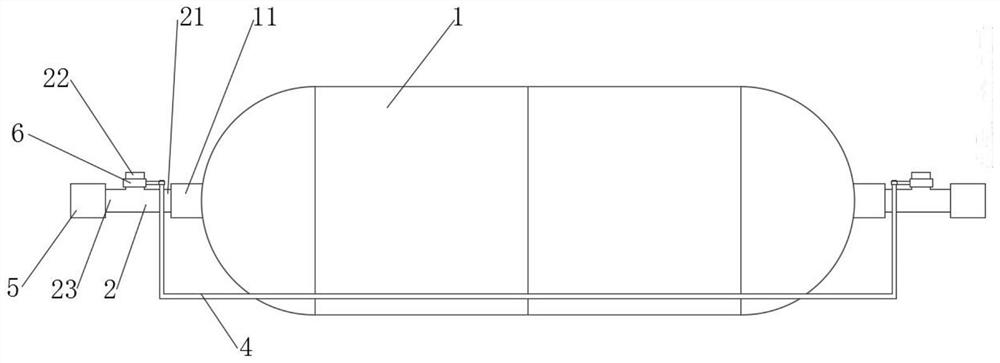

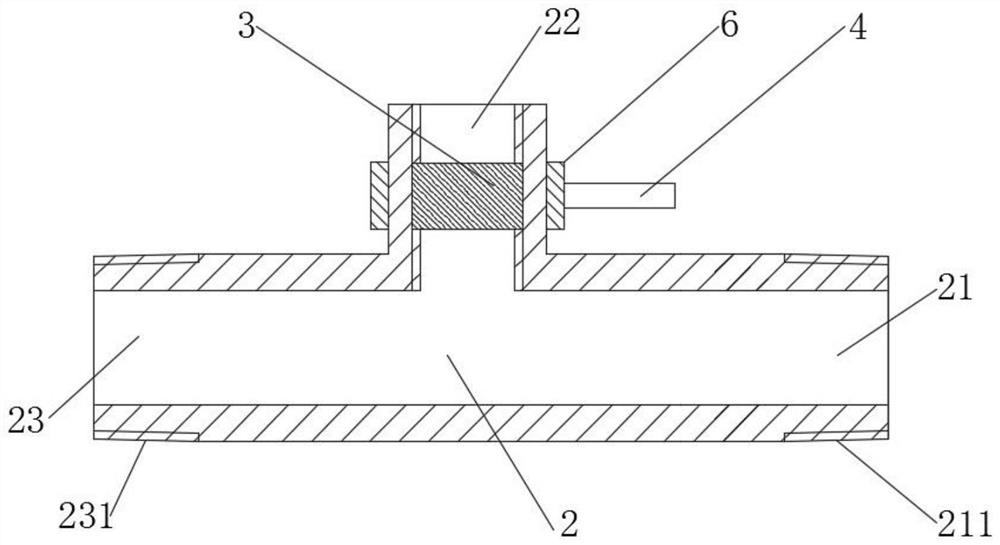

[0028] refer to figure 1 , 3 Shown is an automatic degassing device for temperature sensing in the whole area of the bottle body. The device is communicated with the two bottle body openings 11 at the left and right ends of the gas bottle 1. The device includes: two air guide parts 2, two heat sensitive parts 3, Two heat-conducting members 4 , two valves 5 and two thermal resistance adjusting rings 6 . Wherein, each air guide 2 is provided with an air inlet 21 , a first air outlet 22 and a second air outlet 23 , and an air inlet 21 is communicated with a bottle body opening 11 for connecting the gas cylinder 1 The gas is injected into the two gas guides 2.

[0029] A heat-sensitive element 3 is embedded inside a first air outlet 22 , and a thermal resistance adjusting ring 6 is sleeved outside a first air outlet 22 . Two ends of the heat-conducting member 4 are respectively in contact with a first air outlet 22 , and the heat-conducting member 4 is used for transferring t...

Embodiment 2

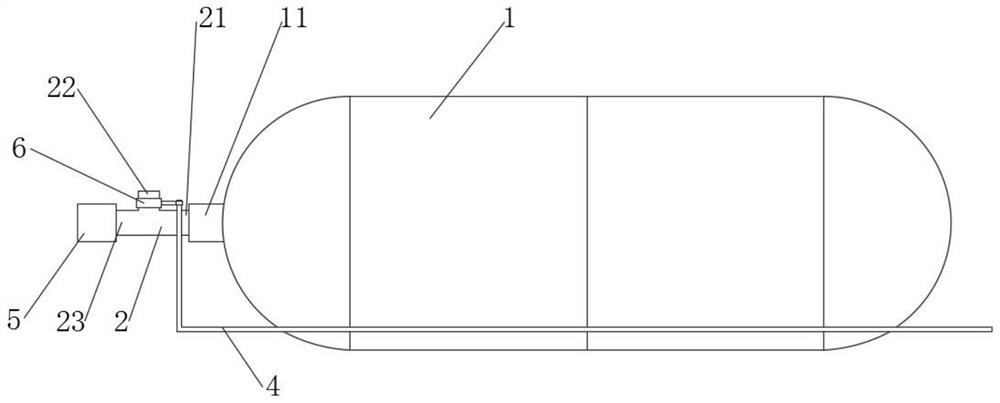

[0044] refer to figure 2 , 3 Shown is an automatic degassing device for temperature sensing in the whole area of the bottle body. The device is communicated with the bottle body mouths 11 at the left and right ends of the gas bottle 1. And the thermal resistance adjustment ring 6 . The air guide 2 is provided with an air inlet 21, a first air outlet 22 and a second air outlet 23. The air inlet 21 communicates with the bottle body opening 11 and is used to inject the gas in the gas cylinder 1 into the air guide 2 in.

[0045] The heat-sensitive member 3 is embedded inside the first air outlet 22 ; one end of the heat-conducting member 4 is in conflict with the first air outlet 22 , and the other end is fitted with the outer wall of the gas cylinder 1 .

[0046] The heat conducting member 4 is used for transferring the heat near the gas cylinder 1 to the thermal resistance adjusting ring 6 . The thermal resistance adjusting ring 6 adjusts different thermal conductivity, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap