Degradable and combustible polyethylene plastics

A polyethylene plastic and polyethylene resin technology, applied in the field of degradable and incinerable plastics, can solve the problems of inability to achieve complete degradation, secondary pollution of the atmosphere, and short exposure time, so as to reduce the generation of dust and carbon monoxide and reduce harmful gases , the effect of reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

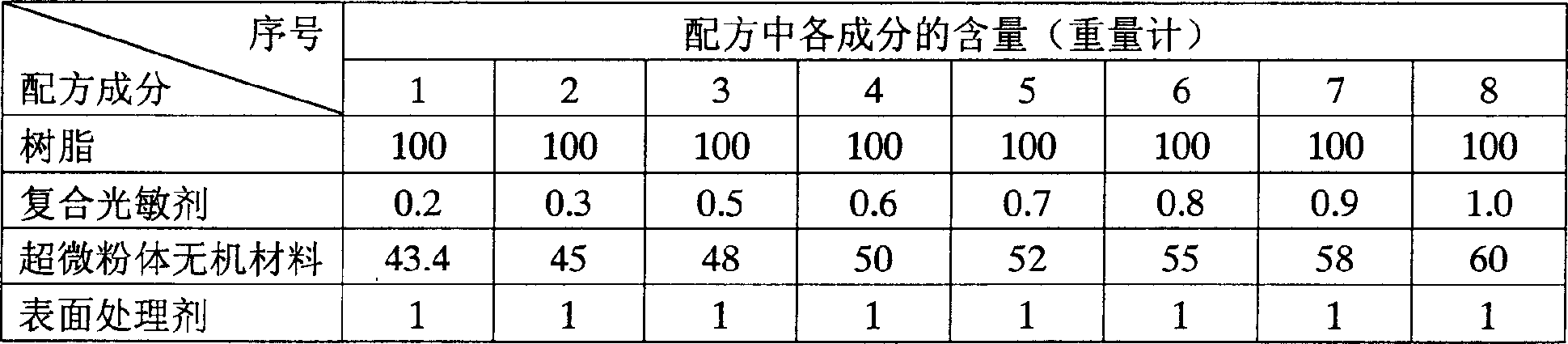

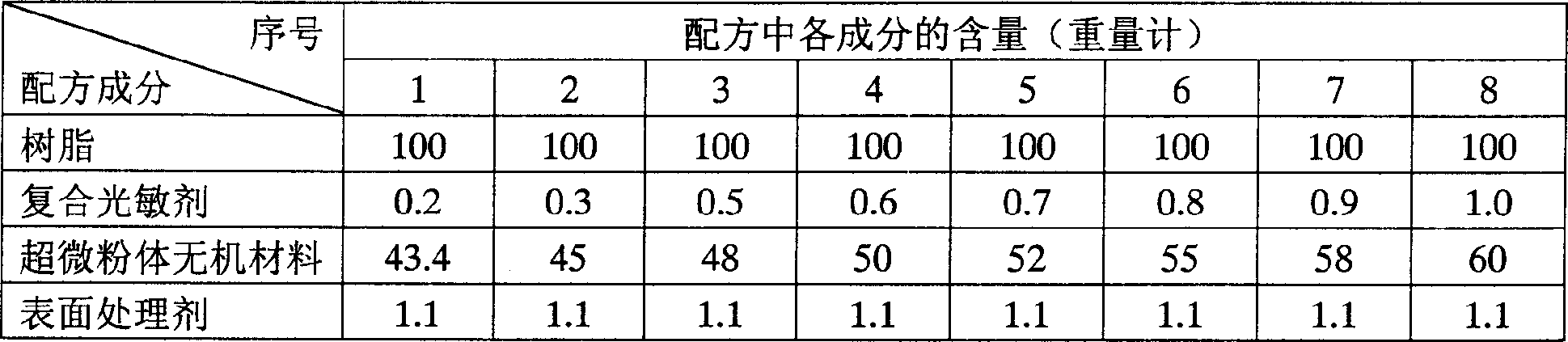

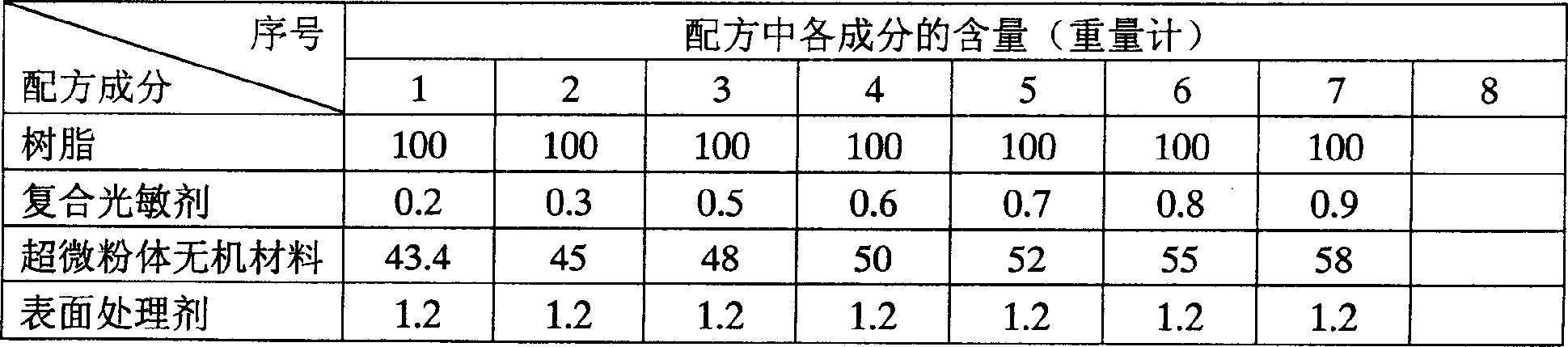

[0045]Each embodiment is described in tabular form below, and each component in Table 1~Table 10 is by weight in the formula. The resin in the table is 100 parts, using high-density polyethylene (HDPE) or low-density polyethylene (LDPE) or a combination of the above two or both and linear low-density polyethylene (LLDPE), the specific combination is shown in Table 11 , shown in table 12, every table is provided with the combination of 16 groups, and when there is linear low density polyethylene component in the combination, the content of linear low density polyethylene (LLDPE) component is 20%~30%, table 1 ~The resin in Table 10 is selected from the combination of any group in Table 11 and Table 12, that is, the formula "1" in Table 1 is 100 parts of resin, 0.2 parts of composite photosensitizer, 43.4 parts of inorganic materials and 1 part of surface treatment agent, Wherein 100 parts of resins can adopt the first combination of high-density polyethylene in Table 11 to accou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com