High-stability remote operation and maintenance system for intelligent factory and use method of high-stability remote operation and maintenance system

A high-stability, operation and maintenance system technology, applied in the direction of comprehensive factory control, coupling devices, casing/cabinet/drawer components, etc., can solve the problem of water vapor, dust and foreign matter adhesion, data lines are easy to fall off, and affect operation and maintenance Manage the normal operation of equipment and other issues to achieve the effect of ensuring stability, avoiding shaking or loosening, and avoiding falling and loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

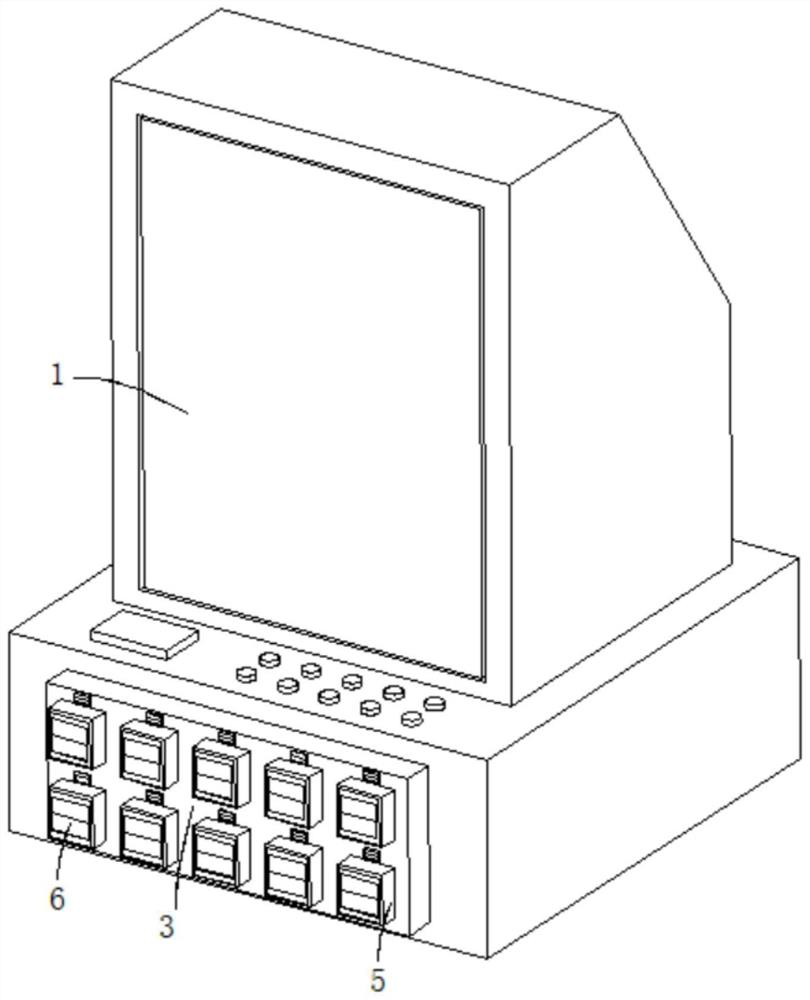

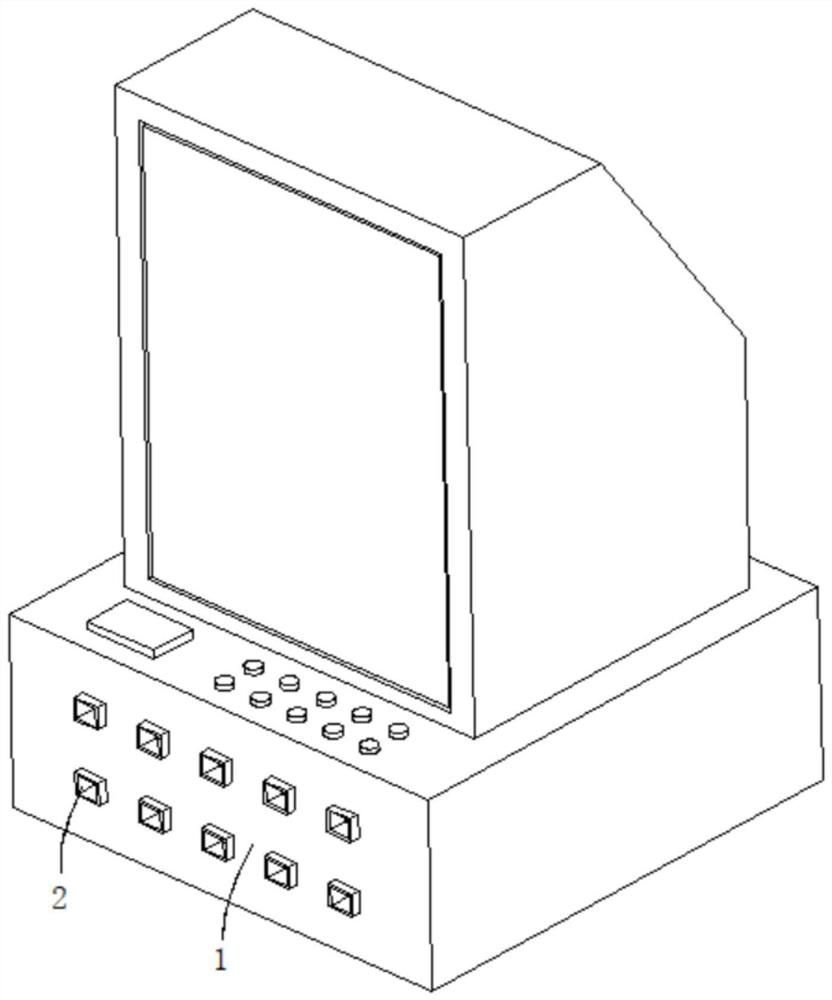

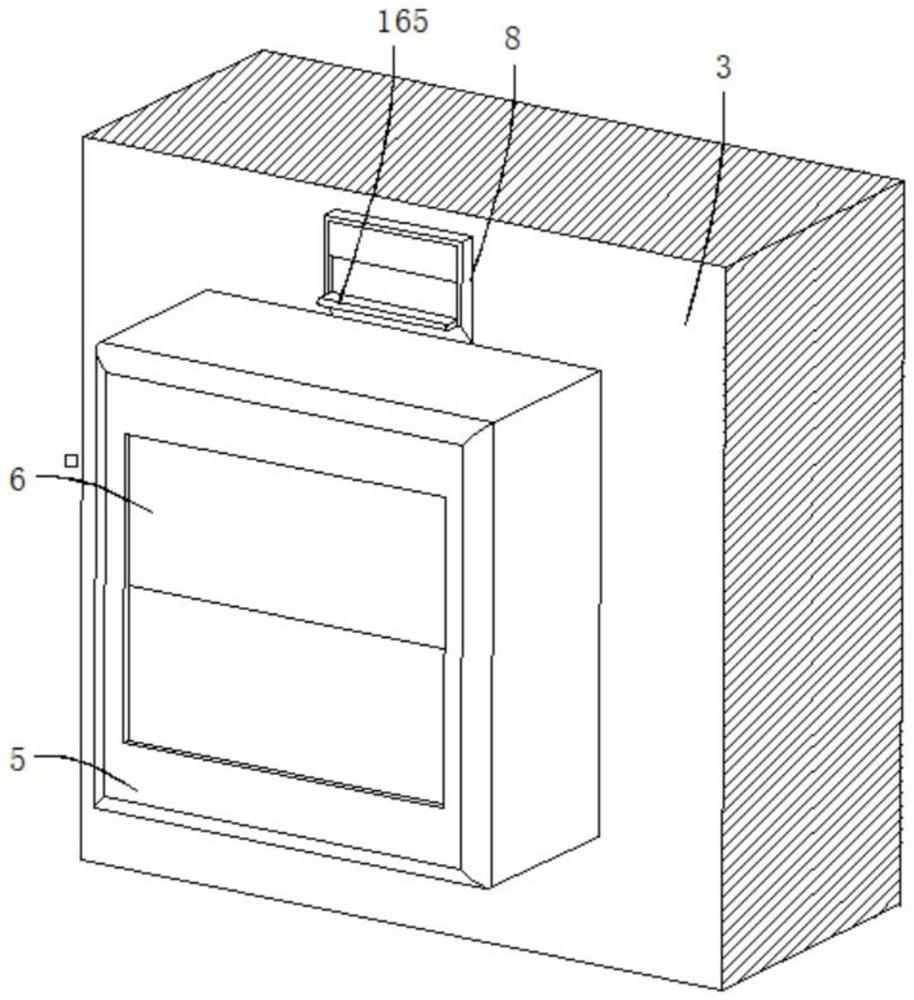

[0044] refer to figure 1 , figure 2 , image 3 , Figure 4 , Image 6 , Figure 7 and Figure 8 , a high-stability remote operation and maintenance system for a smart factory, comprising an operation and maintenance equipment main body 1, a plurality of evenly distributed data line interfaces 2 are opened on the operation and maintenance equipment main body 1, and a mounting plate 3 is arranged on the operation and maintenance equipment main body 1, The mounting plate 3 is placed on the outside of the data cable interface 2, and a plurality of movable slots 4 that cooperate with the data cable interface 2 are opened in the mounting plate 3. Each movable slot 4 is fixed with a card board 401, and the outside of the card plate 401 is sleeved. There is a moving frame 5 , a first elastic telescopic rod 402 is arranged between the clamping plate 401 and the moving frame 5 , a limit plate 8 for restricting the movement of the moving frame 5 is slidably connected to the mountin...

Embodiment 2

[0048] refer to image 3 , Figure 4 , Image 6 and Figure 7 , a high-stability remote operation and maintenance system for a smart factory, the same as in Embodiment 1, further, the rewinding mechanism includes a rewinding groove 9 opened in the moving frame 5, and the inner wall of the rewinding groove 9 is connected by a bearing rotation There is a rewinding shaft 901, which is fixed with one end of the baffle 6, and a first gear 902 is provided on the outer wall of the rewinding shaft 901. The strip 10 and the first gear 902 mesh with each other.

[0049] Further, the moving frame 5 is provided with a slot 11 , and the blocking piece 6 is movably connected in the slot 11 .

[0050] Specifically, the movable frame 5 is pressed into the movable slot 4 of the mounting plate 3 , the first elastic telescopic rod 402 is compressed, and the movable frame 5 is moved into the movable slot 4 . When the movable frame 5 moves into the movable slot 4 , the moving frame 5 slides o...

Embodiment 3

[0052] refer to Figure 4 , Figure 8 and Figure 9 , a high-stability remote operation and maintenance system for smart factories, which is the same as Embodiment 1, and further, the clamping base 7 includes a base 12 fixed on the inner wall of the moving frame 5, and the inner wall of the base 12 is connected with a second The elastic telescopic rod 121 and one end of the second elastic telescopic rod 121 away from the inner wall of the base 12 are connected with a clamping plate 122 , and the clamping plate 122 is slidably connected in the base 12 .

[0053] Further, the base 12 and the outer wall of the clamping plate 122 are respectively provided with a first inclined plane and a second inclined plane, and the first inclined plane and the second inclined plane are on the same plane.

[0054] Specifically, after the shutter 6 is wound by the winding mechanism, the data cable can be inserted into the movable slot 4 of the mounting plate 3 at this time, so that the data ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com