Compression method, decompression method and transmission system for vibration signals of rotating machinery

A technology of rotating machinery and vibration signals, applied in the direction of code conversion, electrical components, etc., can solve the problems of high time cost, low algorithm efficiency, and inability to meet real-time compression transmission, so as to achieve good vibration signal redundancy and improve algorithm efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

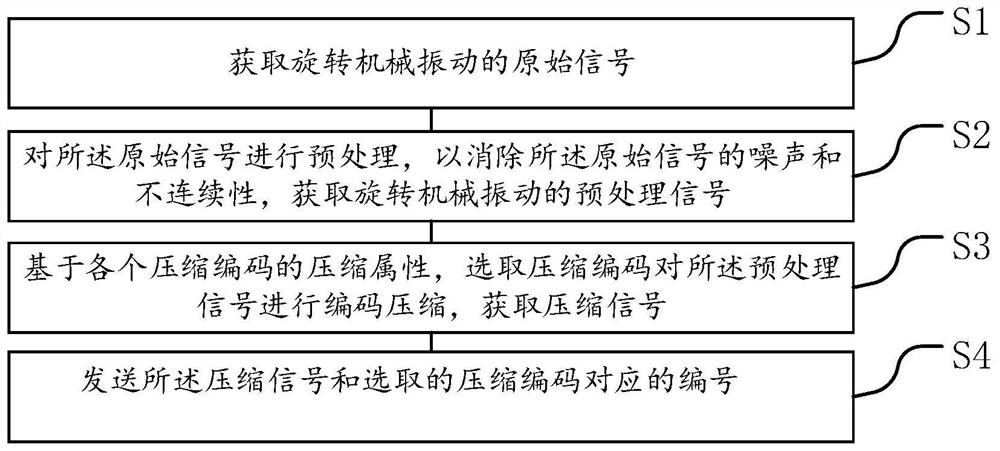

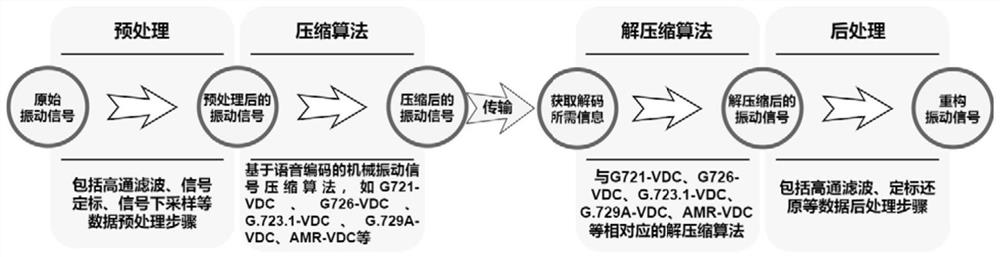

[0044] see Figure 1 to Figure 8 As shown, the first embodiment of the present invention provides a method for compressing a vibration signal of a rotating machine, which can be performed by a device for compressing a vibration signal of a rotating machine. In particular, steps S1 to S4 are implemented by one or more processors within the compression device.

[0045] S1. Obtain the original signal of the vibration of the rotating machinery.

[0046] It can be understood that many devices are equipped with a rotating shaft; the original signal of the vibration of the rotating machine is the measured vibration signal emitted by the rotating shaft during the rotation. By detecting the vibration signal of the rotating shaft, it can be analyzed whether the rotating shaft of the equipment is working normally, so as to analyze the working condition of the equipment.

[0047] The compression device may be an electronic device with computing performance, such as a portable notebook c...

Embodiment 2

[0259] see Figure 9 , a second embodiment of the present invention provides a method for decompressing a rotating mechanical vibration signal, which includes:

[0260] S5. Receive the serial number and the compressed signal. Wherein, the numbered and compressed signals are the numbered and compressed signals mentioned in the first embodiment.

[0261] S6. Decode the compressed signal according to the compression code corresponding to the serial number to obtain a preprocessed signal. Among them, decoding is the inverse process of encoding and compression.

[0262] Specifically, the decompression process is an inverse process of the compression process, and the decompression process of the compression algorithms AMR-VDC, G.729A-VDC and G.723.1-VDC includes steps S61 to S65.

[0263] S61. Decode the received compressed signal to extract LP coefficients {a i } i=1,2,…,10 , codebook vector, gain and other parameters. Wherein the decoding process is the inverse process of th...

Embodiment 3

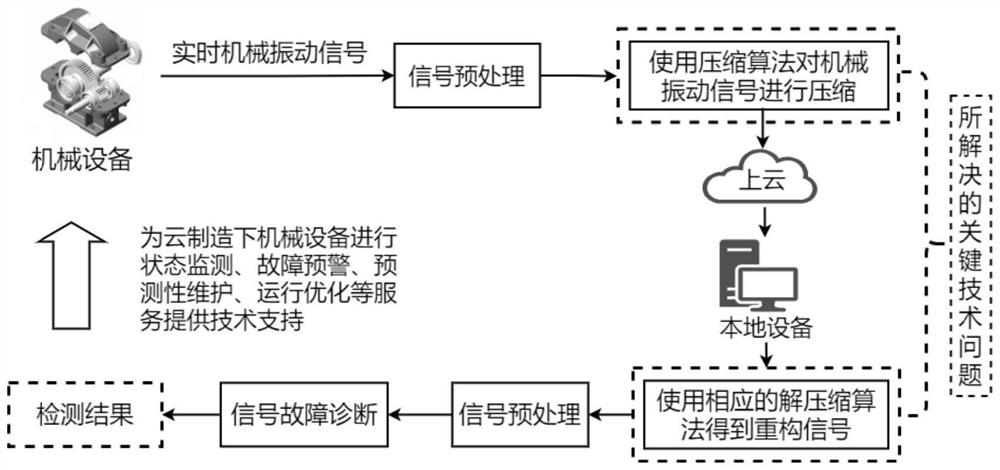

[0277] see figure 2 and image 3 , the third embodiment of the present invention provides a transmission system for rotating mechanical vibration signals, which includes a signal sending device and a signal receiving device.

[0278] The signal sending device is used to realize the following steps:

[0279] S1. Obtain the original signal of the vibration of the rotating machinery.

[0280] S2. Preprocess the original signal to eliminate the noise and discontinuity of the original signal, and obtain the preprocessed signal of the vibration of the rotating machine.

[0281] S3. Based on the compression properties of each compression code, a compression code is selected to encode and compress the preprocessed signal, and a compressed signal is obtained.

[0282] S4. Send the compressed signal and the number corresponding to the selected compression code.

[0283] The signal receiving device is used to realize the following steps:

[0284] S5. Receive the serial number and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com