Integrated intelligent industrial film scanner and system

A scanner and film technology, which is applied in the field of integrated intelligent industrial film scanner and its system, can solve the problems of complex split structure of the scanner, the size is not fixed, and the universality of the scanner is limited, so as to improve the adaptability. , improve applicability, optimize the effect of processing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

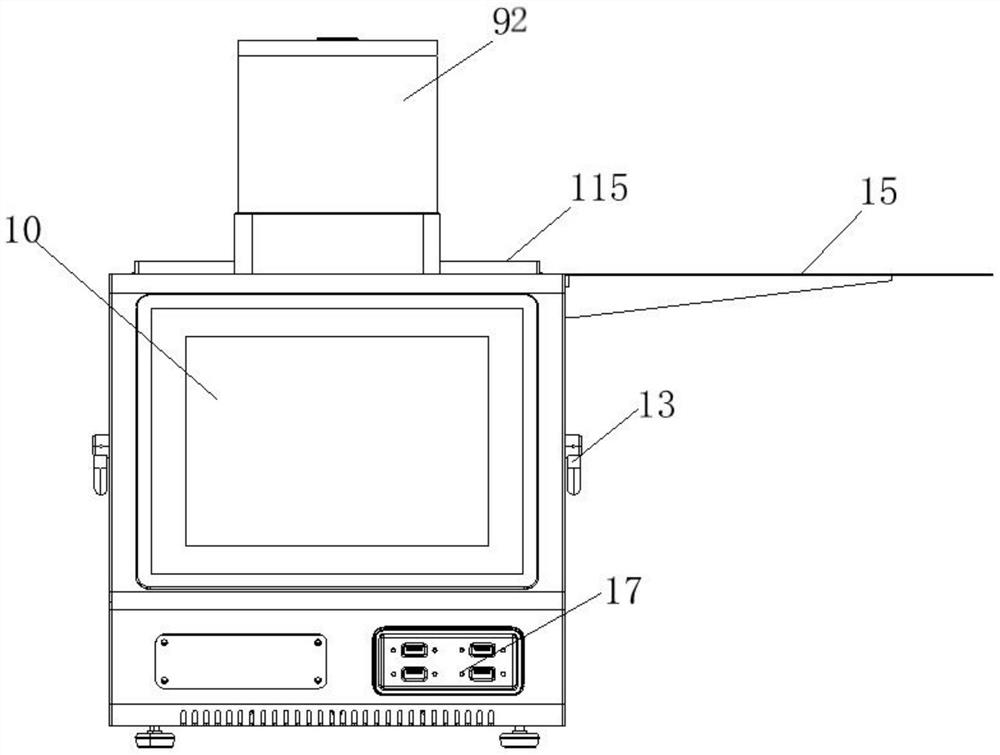

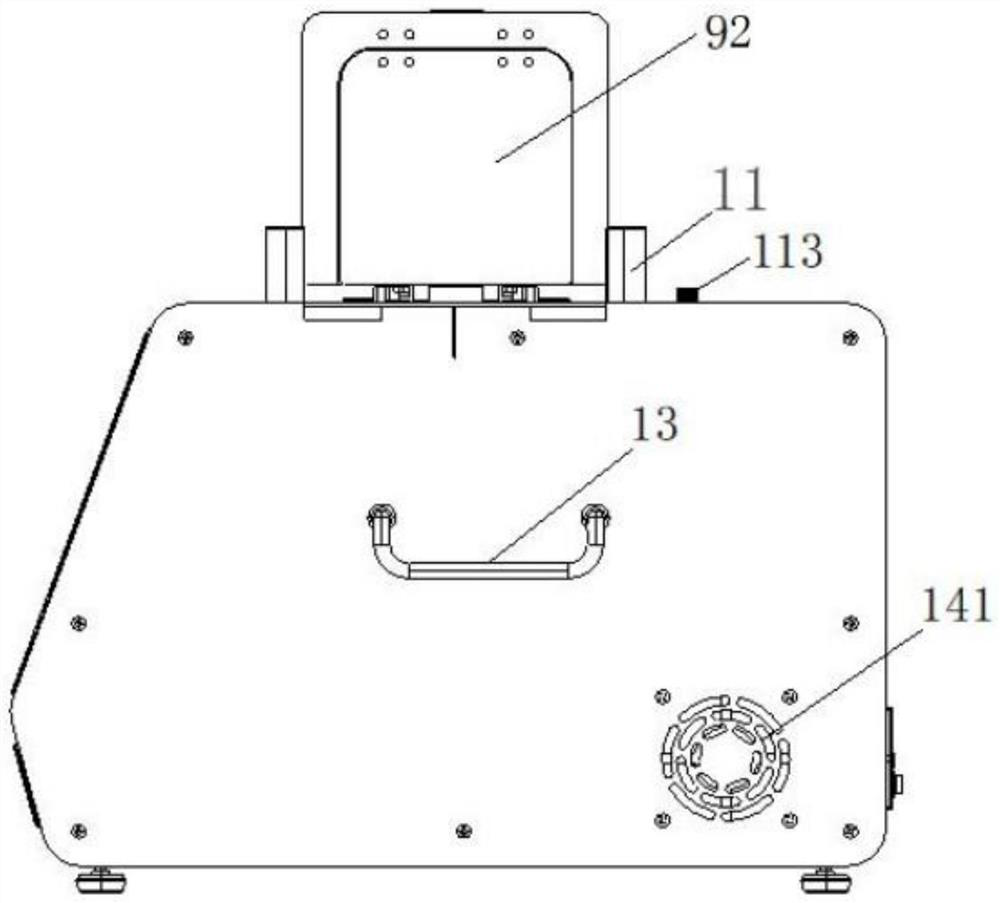

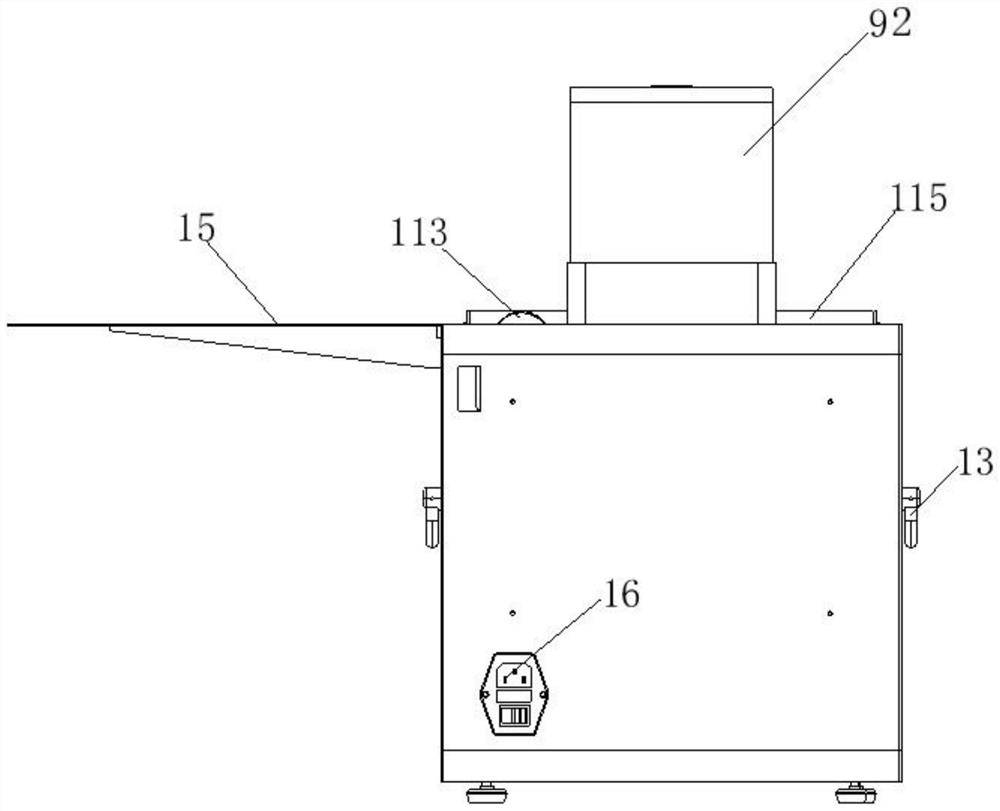

[0061] As an embodiment of the present invention, the film guide slot 11 includes: a support frame 111, and the support frame 111 is fixed on both sides of the light shield 92 by screws;

[0062] Guide rods 112, the number of the guide rods 112 is two, and distributed on both sides between the support frames 111, and both ends of the guide rods 112 are fixed to the support frames 111;

[0063] Rotating the handle 113, the rotating handle 113 is arranged beside the support frame 111 on one side, and is rotatably connected with the supporting frame 111, and the rotating handle 113 penetrates the upper surface of the box body 1;

[0064] A screw rod 114, one end of the screw rod 114 is fixedly connected to the rotating handle 113, and one end of the screw rod 114 away from the rotating handle 113 is rotatably connected to the support frame 111, the screw rod 114 is provided with a thread, and the thread is in the screw Symmetrical opening on the rod 114;

[0065] The slot frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com