Automatic workpiece turning process based on manipulator

A technology of manipulators and automatic vehicles, which is applied in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve problems such as personnel replacement, and achieve the effect of simplifying alignment steps, saving grasping space, and simplifying control difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

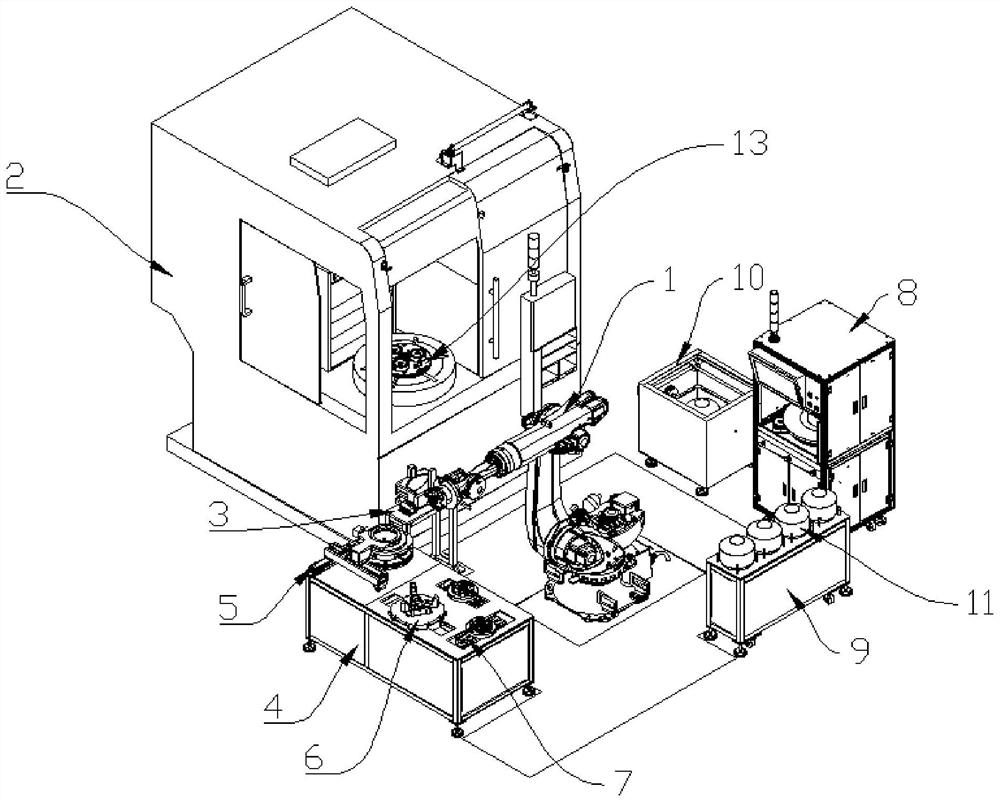

[0057] like Figure 1 to Figure 15 As shown, in order to meet the needs of automatic turning processing of the above-mentioned workpiece 11, the present embodiment designs a turning processing device, which includes a station circulation mechanism and different stations around the station circulation mechanism. The workpiece 11 will be replaced by the station The circulation mechanism grabs and realizes the circulation of the workpiece 11 between different stations, and the different stations are used for corresponding processing of the workpiece 11 .

[0058] In this embodiment, the station circulation mechanism adopts the manipulator 1, and the manipulator 1 is controlled by a corresponding industrial computer. The specific control program is provided by the supplier of the manipulator 1, which will not be repeated here.

[0059] A storage station, a cleaning station, a turning station, a rotation station, an alignment station, a tool placement station and a visual inspectio...

Embodiment 2

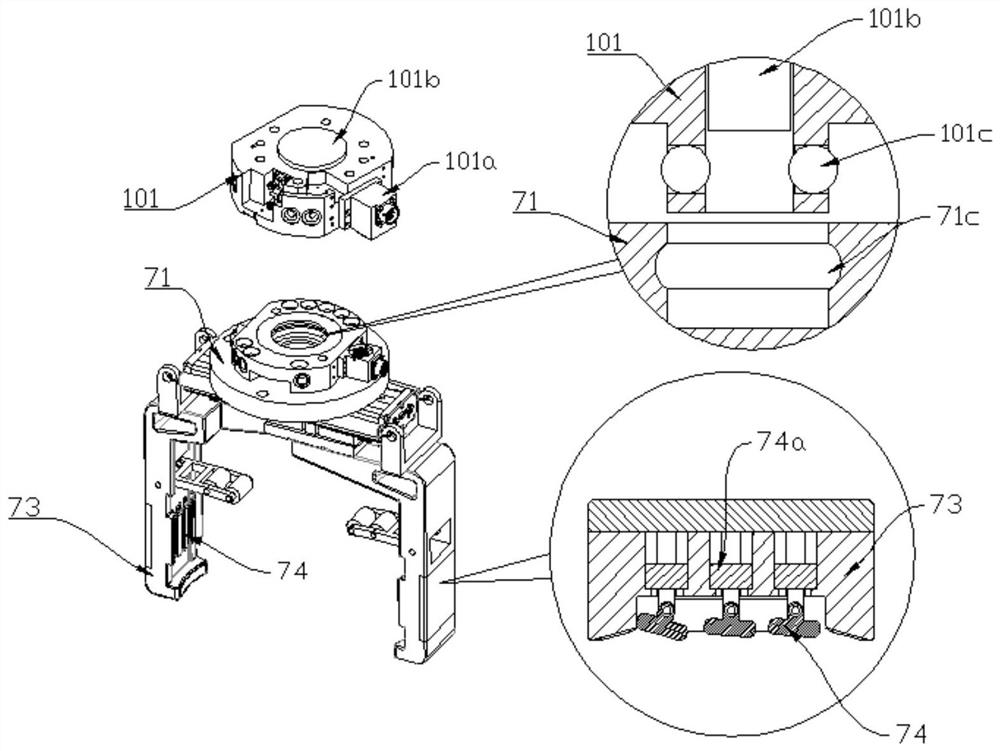

[0061] On the basis of the structure of the first embodiment, in order to realize the rapid replacement of the tooling claw 7 by the manipulator 1 and the manipulation of the tooling claw 7 , the present embodiment designs the tooling claw 7 with the following structure.

[0062] The tooling claw 7 of this embodiment includes a movable connector 71 and a claw assembly. The movable connector 71 is connected to the handle of the claw assembly. The manipulator 1 is provided with a fixed connector 101 matching the movable connector 71. Therefore, the jaw assembly can be quickly assembled on the manipulator 1 .

[0063] An electrical connection male 71a is provided on one side of the movable connector 71, and the connection direction of the two is the same; an electrical connection female 101a is provided on one side of the fixed connector 101, and the connection direction of the two is the same; the dynamic connection When the head 71 is connected to the fixed connection head 101,...

Embodiment 3

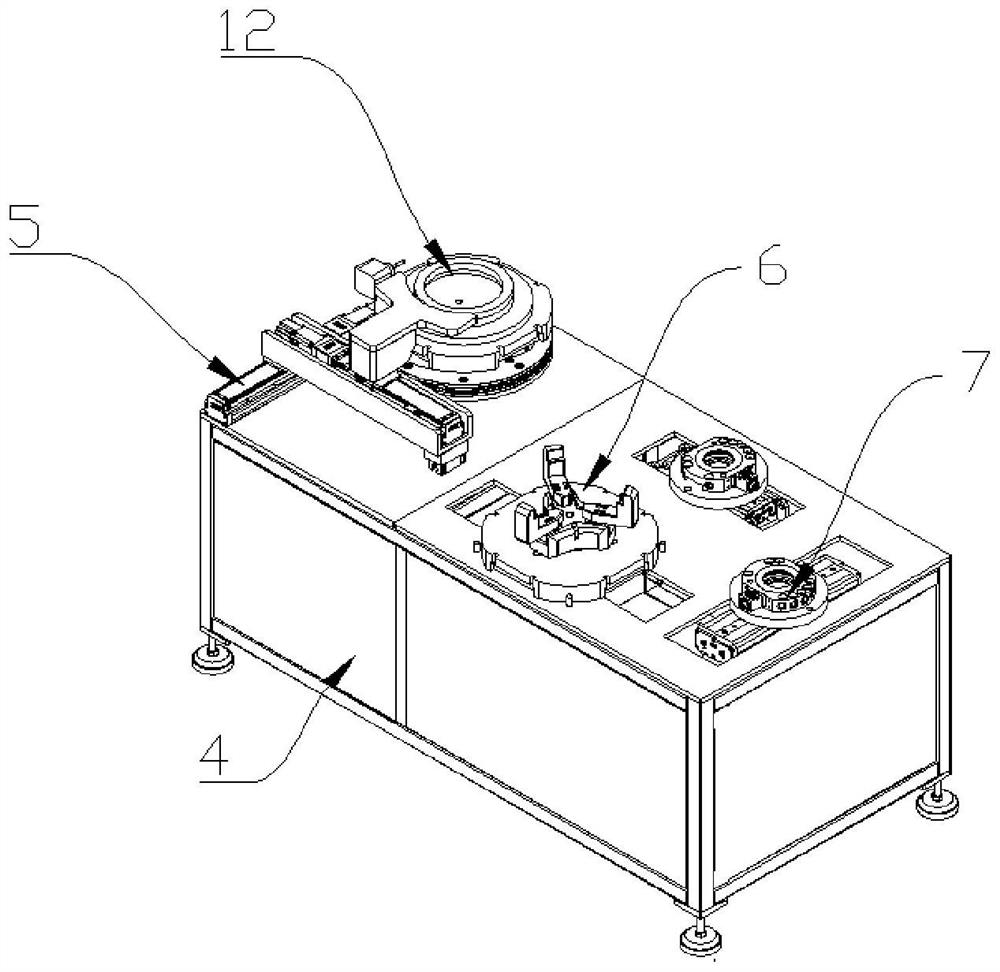

[0071] On the basis of the structure of Embodiment 1, in order to ensure the determination of the center position of the workpiece 11 when turning on the vertical lathe structure 2, it is often necessary to place the workpiece 11 on a carrier for turning, and this embodiment is aimed at this. One problem, the pneumatic chuck 6 and the suction cup assembly 12 are designed that can be used as a carrier for the workpiece 11 .

[0072] The pneumatic chuck 6 includes a chuck positioning plate 62 and a three-jaw pneumatic clamping jaw 61. The chuck positioning plate 62 is disc-shaped, and the three-jaw pneumatic clamping jaw 61 is fixed on the top surface of the chuck positioning plate 62 and is used for the workpiece 11. A plurality of chuck positioning feet 63 are arranged on the bottom surface of the chuck positioning plate 62; a chuck pressure maintaining joint 64 is arranged at the center of the bottom surface of the chuck positioning plate 62, and the chuck pressure maintaining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com