Clamping device for flexibly clamping and detecting rotary motor support assembly workpiece

A motor bracket and clamping device technology, which is applied in the field of aerospace navigation applications, can solve the problems of being unsuitable for mass production and testing of components, limiting the detection efficiency of such workpieces, and taking a lot of time for preparation, so as to save labor costs, Fast changeover and consistent clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with the examples.

[0030] The invention provides a clamping device for flexible clamping to detect the workpiece of a rotary motor bracket assembly, improves the clamping method of the motor bracket assembly workpiece, realizes flexible locking, positioning and clamping; at the same time, it realizes fast workpiece clamping and batch detection. , to realize the detection of flexible clamping of the workpiece and improve the detection efficiency of the workpiece of the motor bracket assembly.

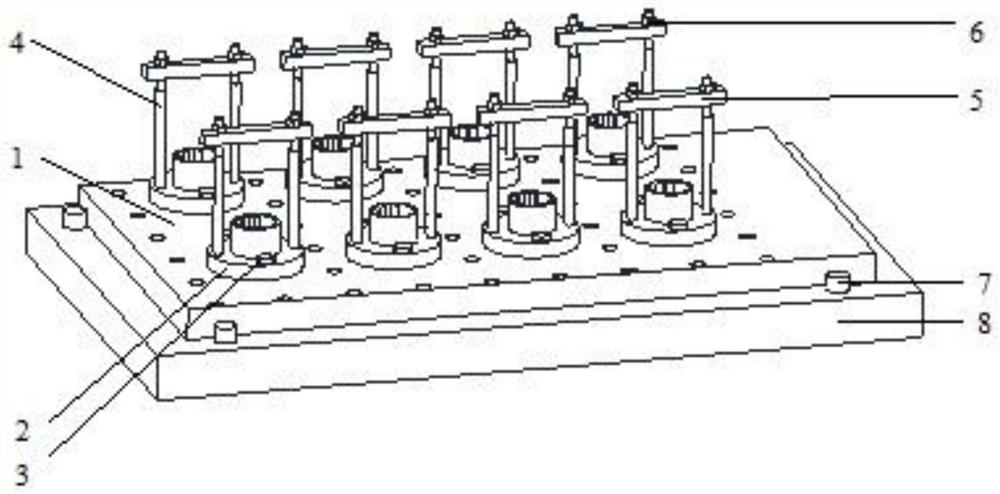

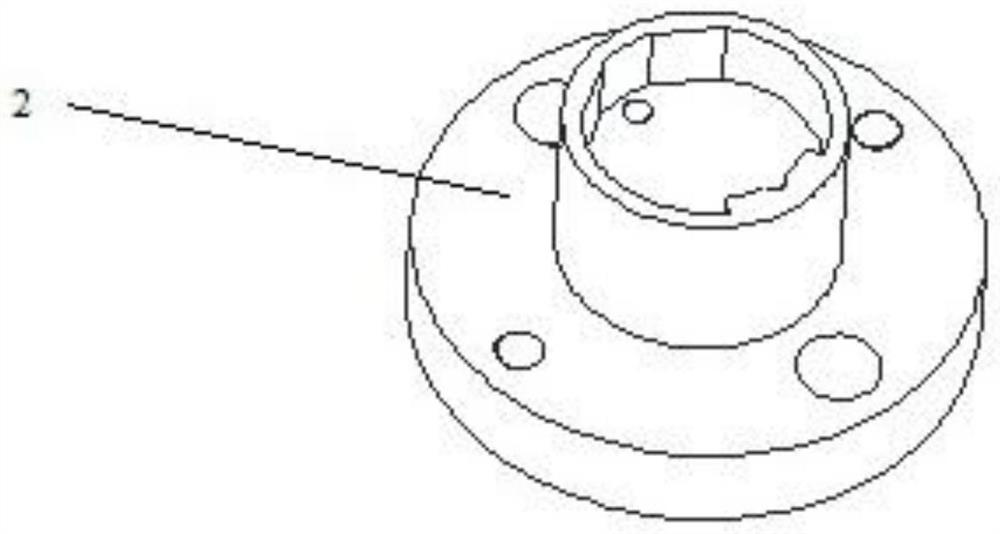

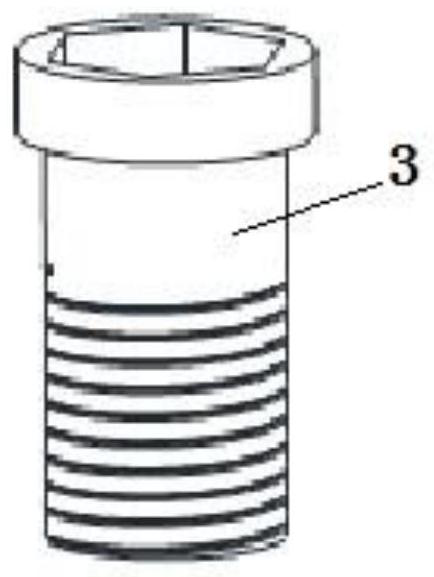

[0031] The flexible clamping device detects the clamping device of the workpiece of the rotary motor bracket assembly, such as figure 1 As shown, it specifically includes a detection substrate 1, a support block 7, a CMM flat plate 8 and n limit mechanisms; wherein, the CMM flat plate 8 is a horizontally placed plate-like structure; the detection substrate 1 is placed horizontally on the three-coordinate The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com