Environment-friendly concrete processing equipment for civil engineering building

An environment-friendly technology for concrete and processing equipment, which is applied to clay preparation devices, mixing operation control, cleaning methods and appliances, etc. It can solve the problems of unsustainable dust removal, dust spillage and scattering, dust collection is too full, etc., and achieve good passability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and embodiments.

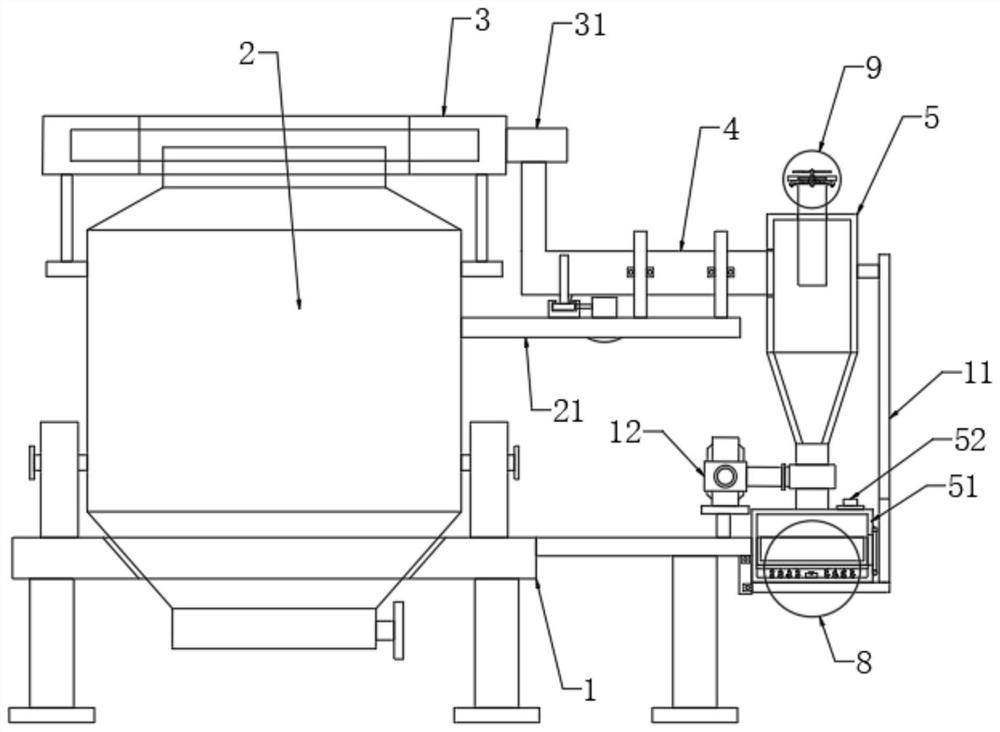

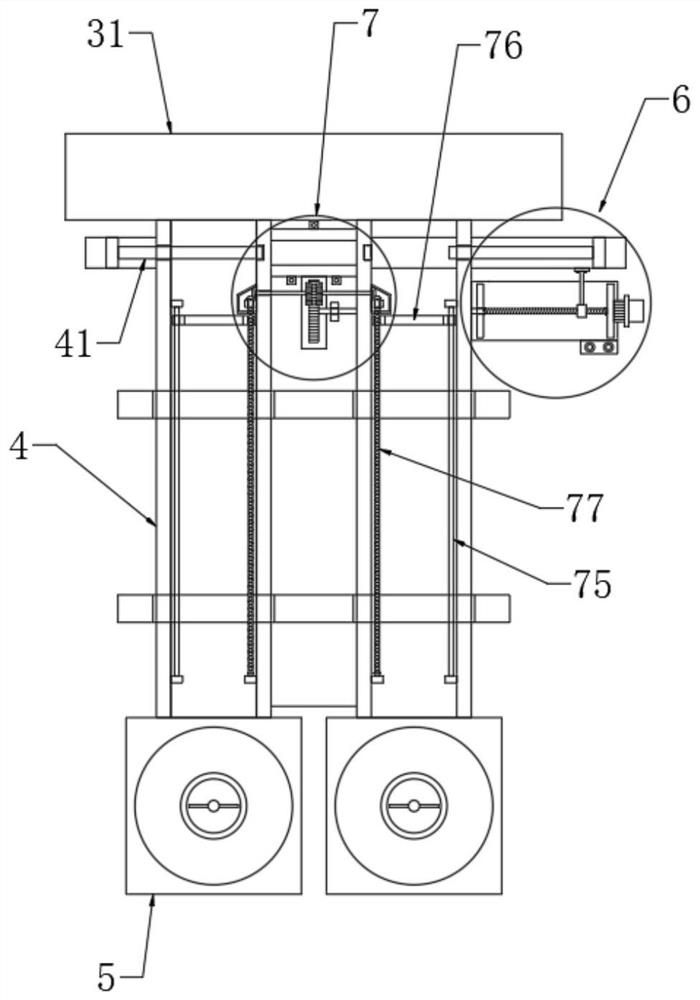

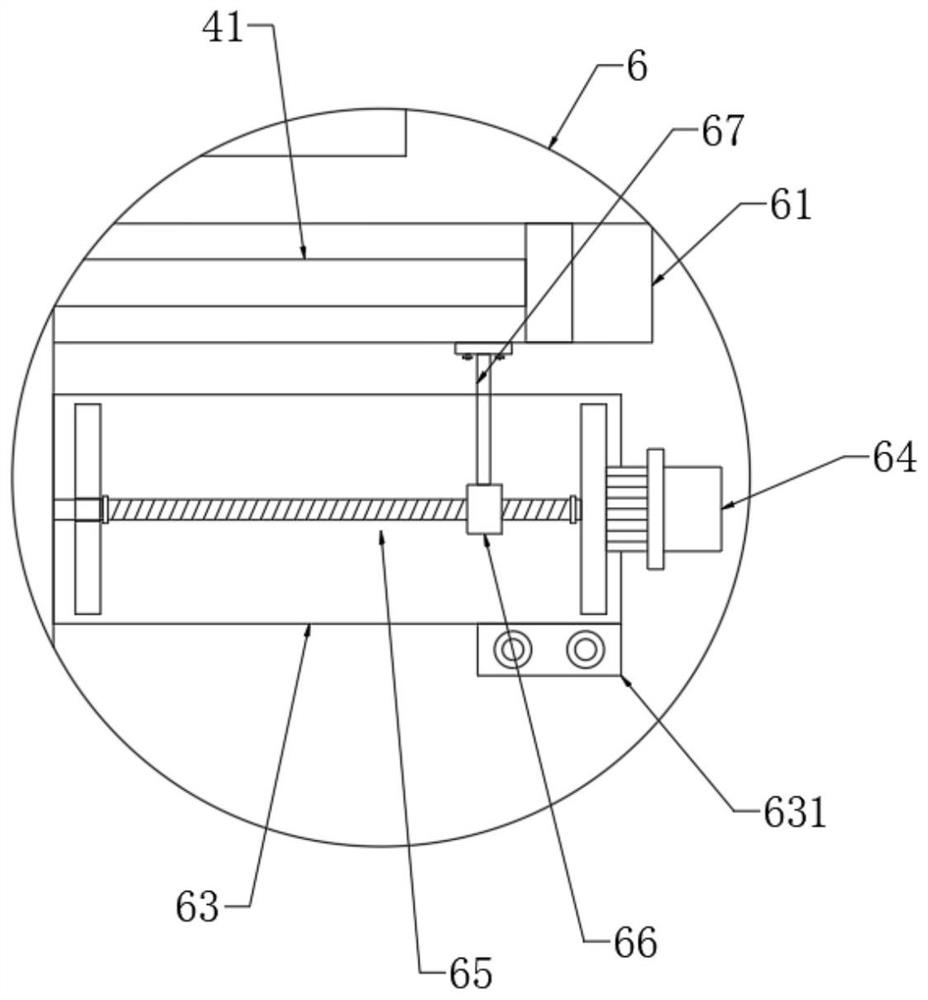

[0026] Please refer to Figure 1 to Figure 6 , an environmentally friendly concrete processing equipment for civil engineering construction includes: a base 1, a mixing tank 2 is fixedly connected to the base 1, a right angle frame 11 is fixedly connected to one end of the base 1, and a tank mouth of the mixing tank 2 is provided with a collecting tank 2 The ring shell 3, the collection ring shell 3 is provided with a double outlet piece 31, the outer wall of the mixing tank 2 is fixedly connected with a straight plate 21, and the straight plate 21 is fixedly connected with two collection pipes 4, and the pipe walls of the two collection pipes 4 are A sliding plate 41 is slidably connected, one end of the two collecting pipes 4 is connected with the double outlet piece 31, and the other end of the two collecting pipes 4 is provided with a separation compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com