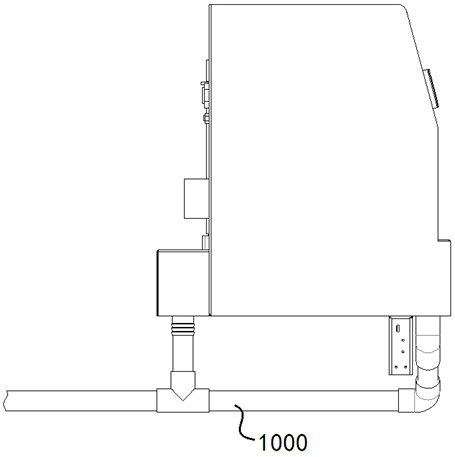

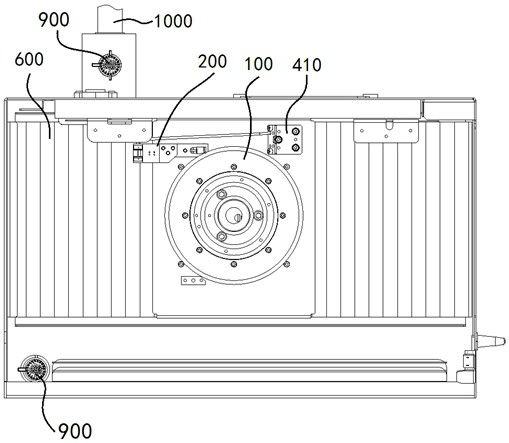

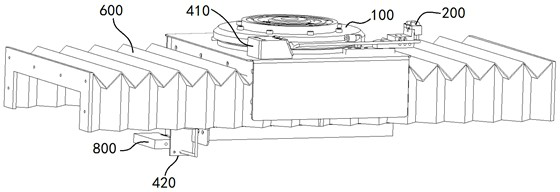

Non-contact height measurement scribing machine

A dicing machine, non-contact technology, applied in the direction of grinding frame, measuring device, grinding machine tool parts, etc., can solve the problems of poor stability of height measurement, signal transmission affected by optical fiber cables, etc., and achieve the goal of improving stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples will be based on the embodiments to clearly and complete the technical scheme of the present invention. Obviously, the embodiment described is part of the embodiments of the invention, not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by ordinary technical personnel in the art under the premise of not creating creative labor belong to the protection of the present invention.

[0027] Technical personnel in this technical field can understand that unless otherwise defined, all the terms (including technical terms and scientific terms) used here have the same significance as ordinary technical personnel in the field of the invention. It should also be understood that the terms defined in the universal dictionary should be understood as the meaning of consistent with the context of the existing technology, and unless it is specifically defined as here, it will not be idealized or too too much. Formal m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com