Method for preparing spar image by using polymethyl methacrylate

A technology of polymethyl methacrylate and methyl methacrylate, which is applied in the process of producing decorative surface effects, special decorative structures, decorative arts, etc., can solve the problem of poor image detail reduction, lack of aesthetics, The color fidelity of the finished product is not high enough to achieve the effect of good image reproduction, light weight and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

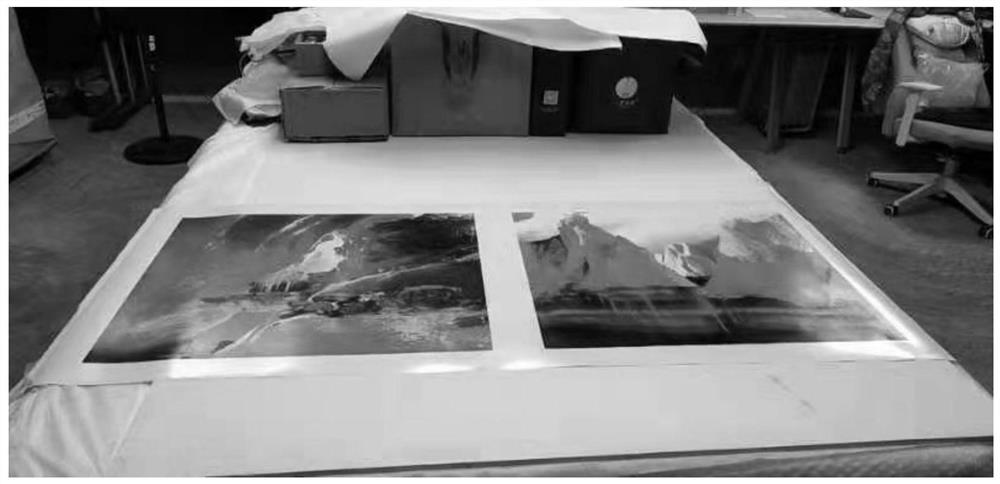

[0040] like Figures 1 to 2 As shown, the present embodiment provides a method for preparing a spar image by using polymethyl methacrylate, comprising the following steps:

[0041] 1) get the methyl methacrylate of 31%, the polymethyl methacrylate of 69%, carry out stirring, the viscous slurry M after stirring is poured into the mould, and the pouring thickness is 8 centimeters, then carry out The temperature is the polymerization of 8 ℃, after 50 minutes of polymerization and a layer of hard film is formed on the surface, then put into the autoclave, and the low temperature polymerization of 40 ℃ is carried out in the autoclave successively, and the polymerization time is 2 hours and the medium temperature of 68 ℃. Polymerization, polymerization time is 3 hours, high temperature polymerization at 100 ° C, polymerization time is 8 hours, after the viscous slurry M completes the polymerization reaction, the pressure holding temperature reaches 27 ° C, and then the autoclave is ...

Embodiment 2

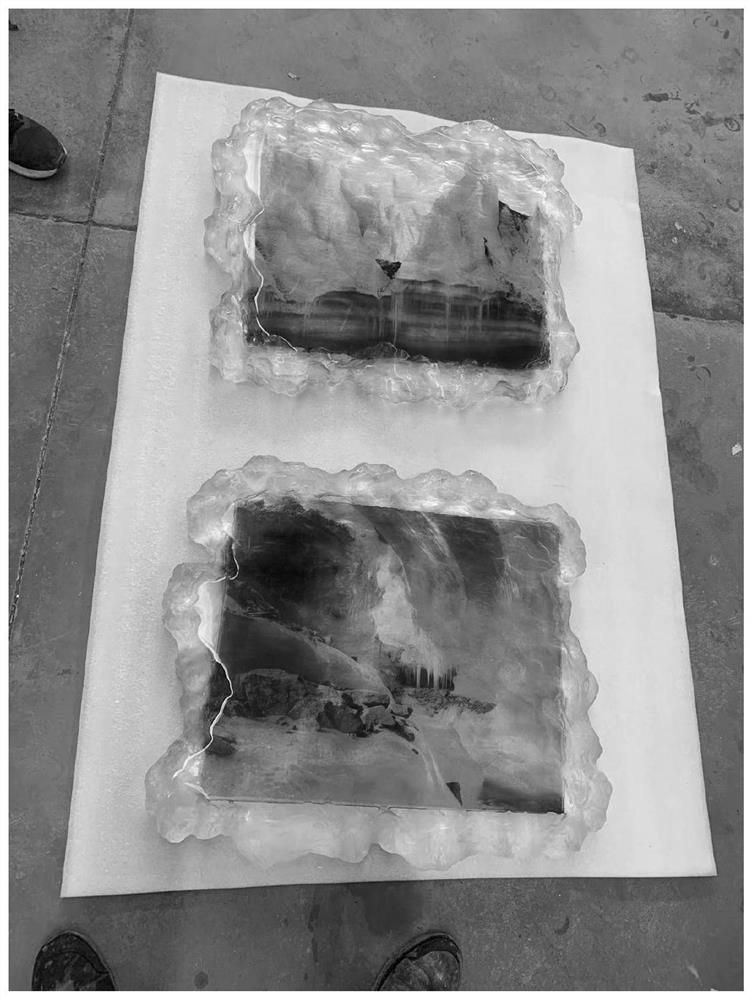

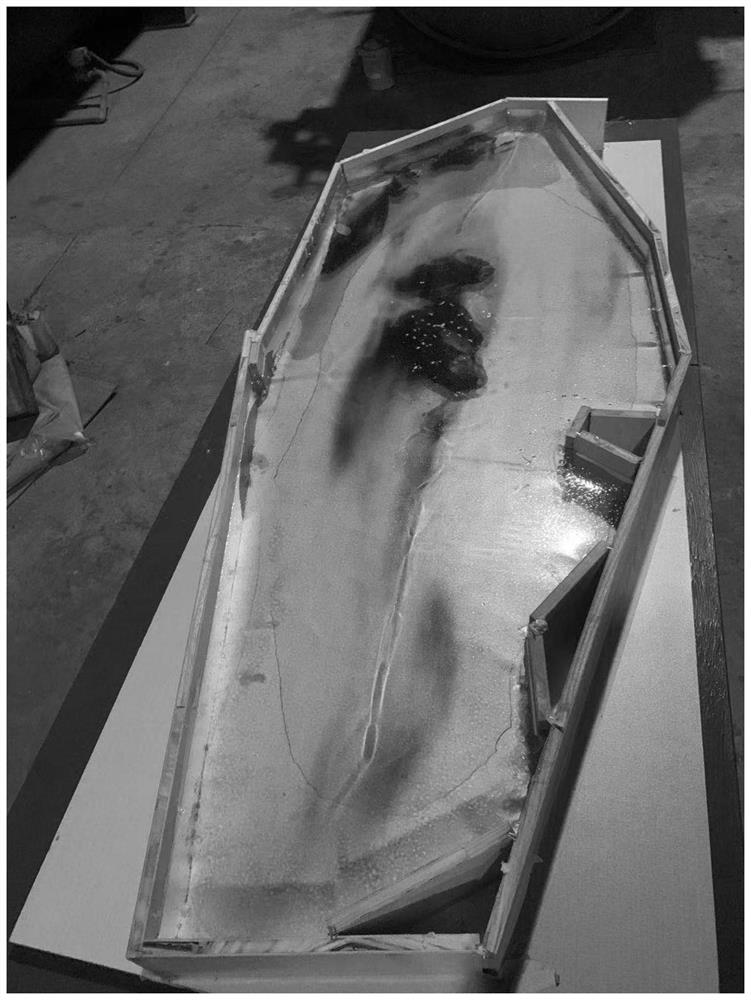

[0050] like Figures 3 to 5 As shown, the present embodiment provides a method for preparing a spar image by using polymethyl methacrylate, comprising the following steps:

[0051]1) Take the mass percentage of 32% methyl methacrylate, 67% polymethyl methacrylate, 0.3% plasticizer, 0.7% coloring agent and stir, and pour the stirred viscous slurry M To the mold, and the pouring thickness is 10 cm, and then carry out the polymerization at a temperature of 10 ° C, after 50 minutes of polymerization and a layer of hard film is formed on the surface, put it into the autoclave, and in the autoclave, perform a low temperature of 40 ° C in turn. Polymerization, polymerization time is 3 hours, medium temperature polymerization at 70 ° C, polymerization time is 3 hours, high temperature polymerization at 100 ° C, polymerization time is 8 hours, after the viscous slurry M completes the polymerization reaction, the pressure holding temperature reaches 20 ° C, and then Only open the autoc...

Embodiment 3

[0059] The present embodiment provides a method for preparing a spar image using polymethyl methacrylate, comprising the following steps:

[0060] 1) Take 35% of methyl methacrylate, 64% of polymethyl methacrylate, 0.4% of plasticizer, 0.3% of coloring agent, 0.3% of benzoyl peroxide by mass and stir, The stirred viscous slurry M is poured into the mold, and the pouring thickness is 25 cm, and then the polymerization is carried out at a temperature of 20 ° C. In the autoclave, low-temperature polymerization at 50° C. was carried out in turn, the polymerization time was 5 hours, and the medium-temperature polymerization at 89° C. was carried out. The polymerization time was 4 hours and the high-temperature polymerization at 110° C. The polymerization time was 9 hours. After the pressure holding temperature reaches 10℃, the autoclave is opened, and the spar A is taken out and polished; the pressure parameter of the autoclave is 0.8MPa;

[0061] 2) The image is printed on the UV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com