Bag type self-generating dynamic membrane high-efficiency solid-liquid separation device

A solid-liquid separation and dynamic membrane technology, applied in the field of water treatment, can solve the problems of limiting the application range and effect of dynamic membrane devices, low structural flexibility of dynamic membrane support bodies, and low volume load rate of dynamic membrane devices, etc. Utilization rate, improving oxygen utilization rate, and reducing the effect of occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

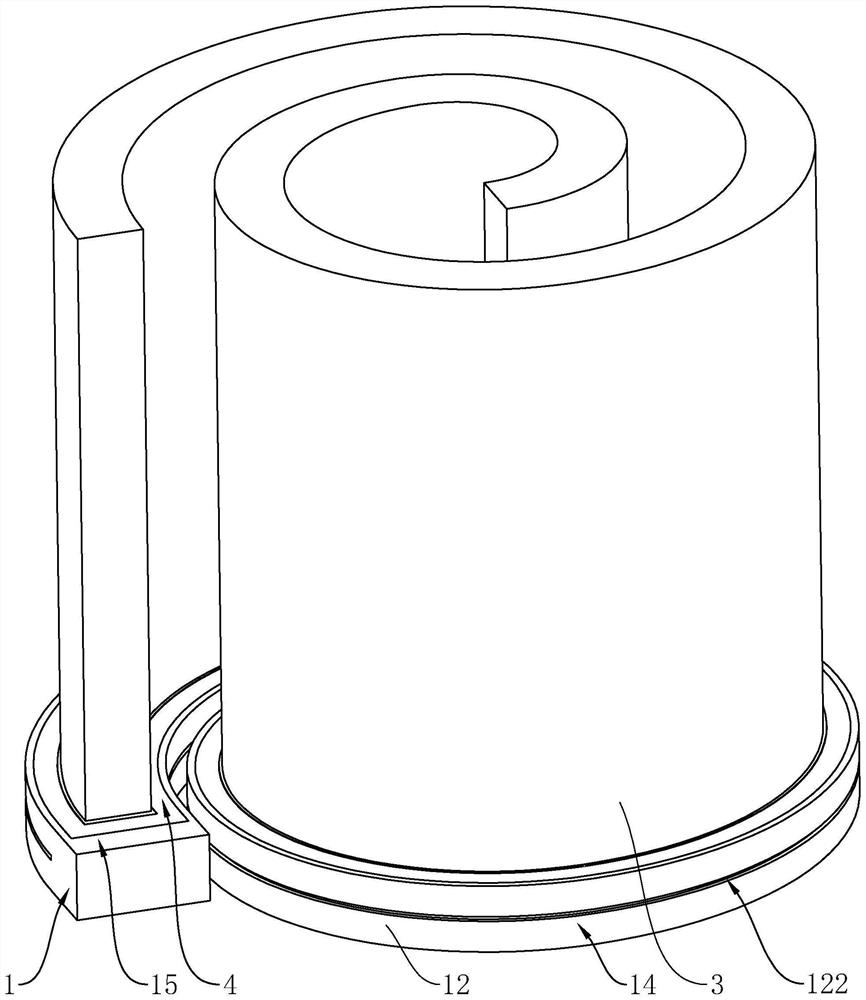

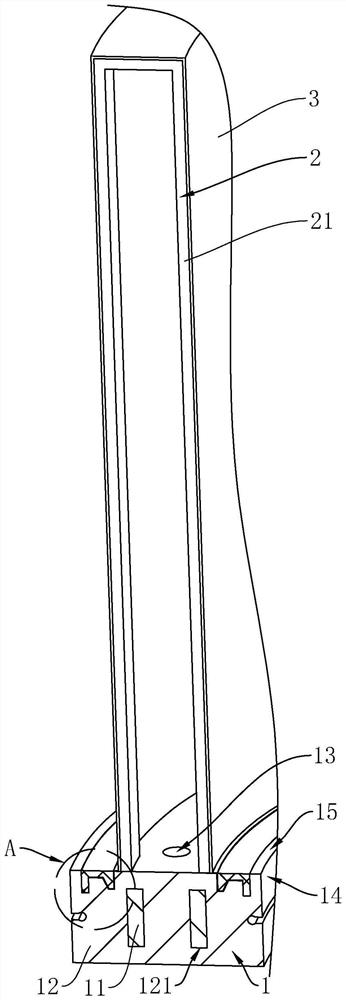

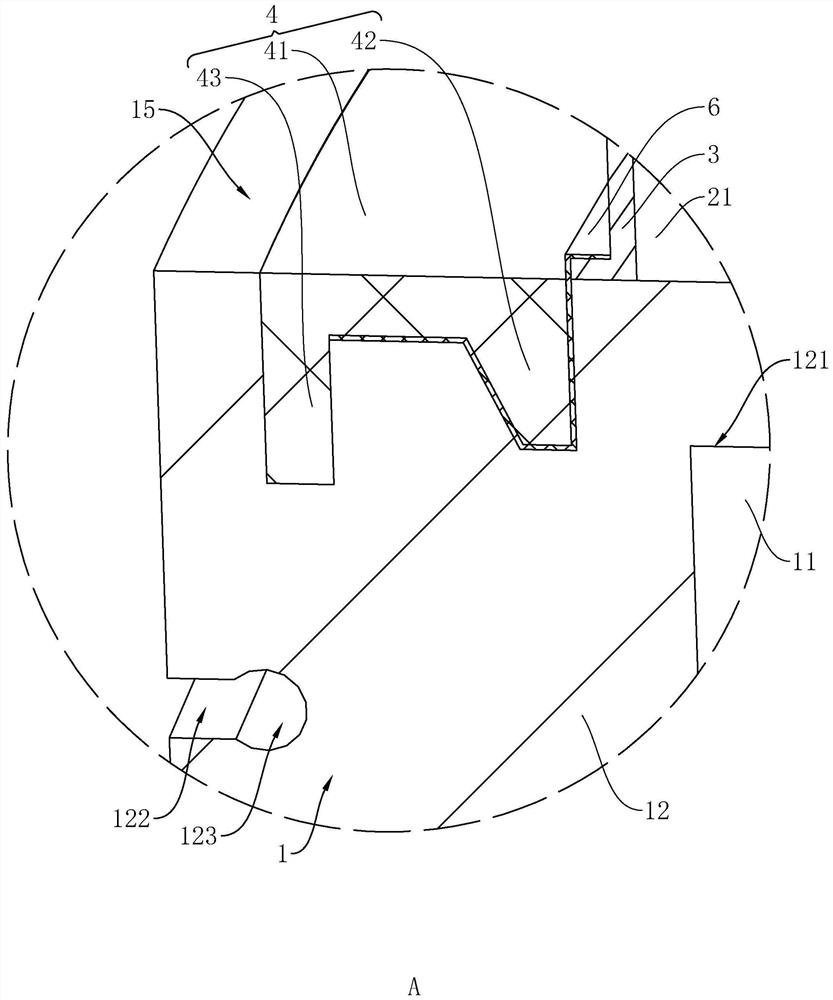

[0050] Examples of this application 1 reveal a pocket -type self -living dynamic film high -efficiency solid liquid separation device. Reference figure 1 and figure 2 , The solid -liquid separation device includes basic branches 1. Supporting parts 2, membrane bags 3, sealing parts 4 and setting components 5. Basic support 1 is a long -strip square branch that can be bent in the direction of length. Basic branch 1 has four side walls along the length direction. The side wall is the flat side wall 15, the plane side wall 15 and the surface wall 14 staggered cloth.

[0051] Among them, the support parts 2 is installed on one of the plane side wall 15, 3 sets of film bags are set on supporting parts 2, and the support parts 2 pairs of film bag 3 shall reduce the probability of fitting the inner wall of the film bag 3. like image 3 Show, the surrounding area of the film bag 3 is sutured and fixed with flexible material connection seal 6, connected to seal 6 and the side wall of the ...

Embodiment 2

[0070] The difference between the embodiment of this application and the embodiment 1 is: Refer to reference Figure 5 , Basic support is bent in the direction of the length into a ripple shape, and several setting sliders 51 are located at each bending point on the basic support of the base support. There are two setting sliders 51 at the curved point located at the same basic support, and the two setting sliders 51 are set up and connected by the setting thicker 52, so as to set the wave pattern base support.

[0071] The ripple -shaped solid -liquid separation equipment not only reduces the occupation space of the overall equipment, increases the volume load rate of dynamic film device, and also increases the contact area of the sewage and dynamic film in the same pool space compared with the spiral shape. Shorten the contact distance between the sewage and the dynamic film, thereby increasing the purification rate of the sewage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com