Preparation method of wide-range fluorine grease

A production method and technology of fluorine oil, which are used in lubricating compositions, petroleum industry, etc., can solve the problems of unsatisfactory friction performance indicators, high temperature performance indicators, easy cracking, oil separation, and poor grease-forming state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

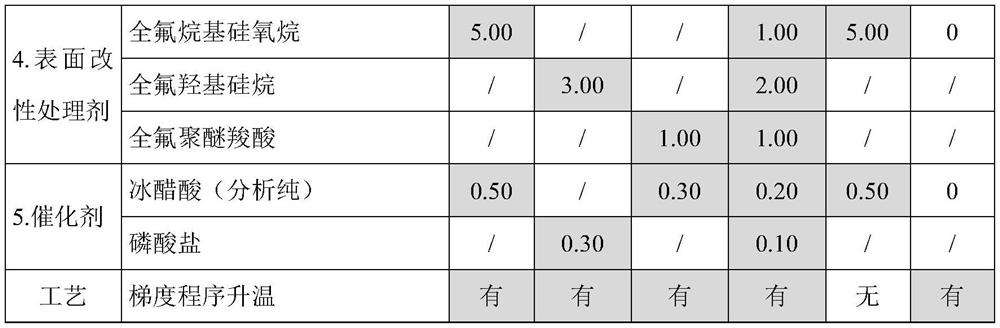

[0030] This embodiment 1 (also includes four specific embodiments 1A, 2A, 3A, and 4A, only the material selection is different) adopts the method of comparing with the other two embodiment cases 1B and 1C at the same time. Among them, 1B adopts the exact same material as 1A in this embodiment, and does not adopt the temperature-programmed method in the production process; and 1C adopts the completely same temperature-programmed method as in the first embodiment, but the material ratio is changed. The specific parameters are shown in Table 1 below.

[0031] Table 1

[0032]

[0033]

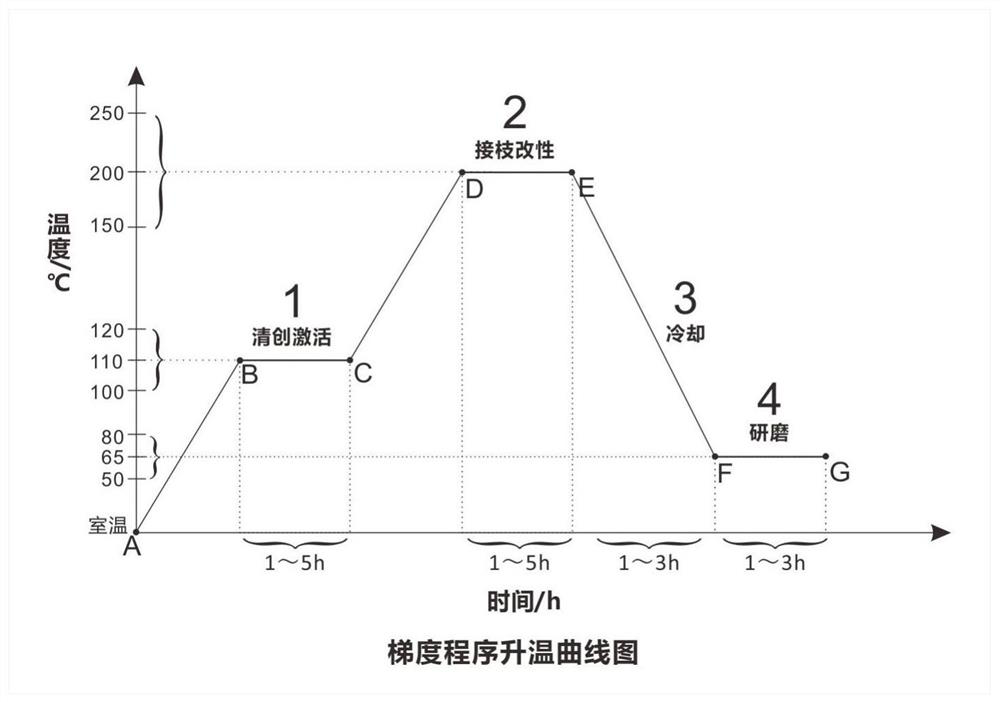

[0034] Wherein, the curve of the gradient temperature programming of the in-situ reaction in the first embodiment is completely in accordance with the figure 1 set up. Among them, the debridement activation stage is the BC section, and the temperature / time is 110 °C / 3h; the CD section is the natural temperature rise stage; the grafting modification stage is the DE section, and the temperat...

Embodiment 2

[0038] Similarly, the second embodiment is used for comparison test with another implementation case 2B. Among them, 2B adopts the exact same temperature programming method as in Example 2, but the material does not contain debridement activator, modified treatment agent and catalyst.

[0039]The material ratio of each embodiment and technology are shown in table 2 below

[0040] Table 2

[0041]

[0042] Wherein, the gradient temperature-programmed curve of the in-situ reaction in the present embodiment is completely in accordance with figure 1 set up. Among them, the debridement activation stage is the BC section, and the temperature / time is 100 °C / 5h; the CD section is the natural temperature rise stage; the grafting modification stage is the DE section, and the temperature / time is 250 °C / 2h.

[0043] It can be seen from the test that the product of Comparative Example 2B is easy to crack, while the product of Example 2 prepared by the method of the present invention ...

Embodiment 3

[0045] Similarly, the third embodiment is compared with another implementation case 3B. Among them, 3B adopts the same material as in Example 3, but there is no segmented temperature rise.

[0046] The material proportioning and technology of each embodiment are shown in the following table 3

[0047] table 3

[0048]

[0049] Wherein, the gradient temperature-programmed curve of the in-situ reaction in the present embodiment is completely in accordance with figure 1 set up. Among them, the debridement activation stage is the BC section, and the temperature / time is 120 °C / 1h; the CD section is the natural temperature rise stage; the grafting modification stage is the DE section, and the temperature / time is 150 °C / 5h.

[0050] Comparing Example 3B, there is no staged temperature rise. BC segment, CD segment, DE segment: all at 120°C, kept for 6 hours.

[0051] The test shows that the product of Comparative Example 3B is easy to crack, while the product of Example 3 prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com