Gas recovery oxygen content analyzer and method thereof

An oxygen content analyzer and gas technology, which are applied in the fields of material magnetic variables, preparation of samples for testing, sampling devices, etc., to achieve the effect of improving work efficiency, reducing pipeline medium contact, and ensuring operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

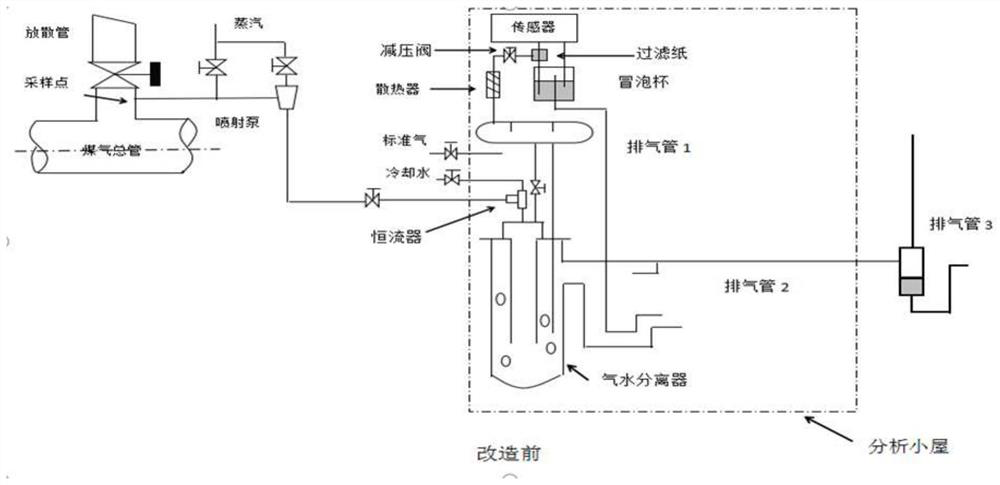

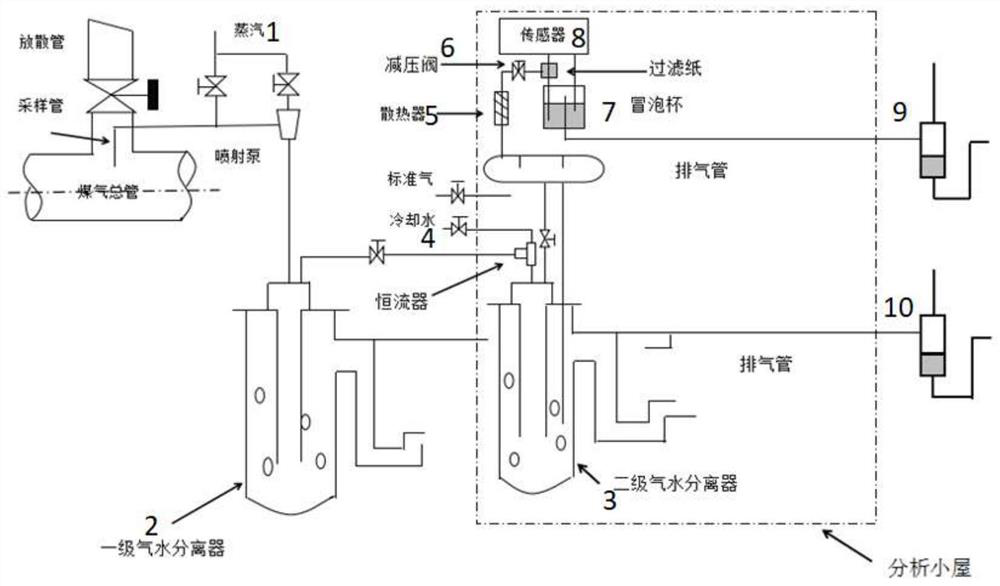

[0044] like figure 2 As shown, a gas recovery oxygen content analyzer is shown, including a steam jet pump 1, a primary gas-water separator 2, a secondary gas-water separator 3, a cooling water device 4, a radiator 5, and a pressure reducing valve 6 , the bubbling cup 7, the sensor 8, the first exhaust pipe 9 and the second exhaust pipe 10, the steam jet pump 1 is connected to the gas pipeline, the primary gas-water separator 2 and the cooling water device 4 are confluent and then connected to the secondary gas The water separator 3, the secondary gas-water separator 3, the radiator 5, and the pressure reducing valve 6 are connected in sequence, the bubbling cup 7 and the sensor 8 are connected in parallel with the pressure reducing valve 6, and the first exhaust pipe 9 is connected with the bubbling cup 7, The second exhaust pipe 10 is connected to the secondary gas-water separator 3 .

[0045] In this embodiment, the steam jet pump is connected to the gas main.

[0046] I...

Embodiment 2

[0050] The using method of a kind of gas recovery oxygen content analyzer of embodiment 1, comprises the following steps:

[0051] S1. Connect the sampling pipe to the gas main pipe;

[0052] S2. Preparation before detection: steam purge the sampling pipe from the sampling port to the steam jet pump, keep the sampling pipe in front of the steam jet pump at positive pressure, and ensure that the sampling pipe in front of the steam jet pump is in good sealing condition;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com