Double-framework common-winding current transformer structure and design method thereof

A winding current and structure design technology, applied in the manufacture of inductors, transformers/inductor cores, inductors/transformers/magnets, etc., can solve problems such as high cost, poor transient characteristics, and small dynamic range, and achieve anti-saturation Strong ability, improved anti-saturation point, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0144] Below in conjunction with accompanying drawing, the present invention is described in further detail:

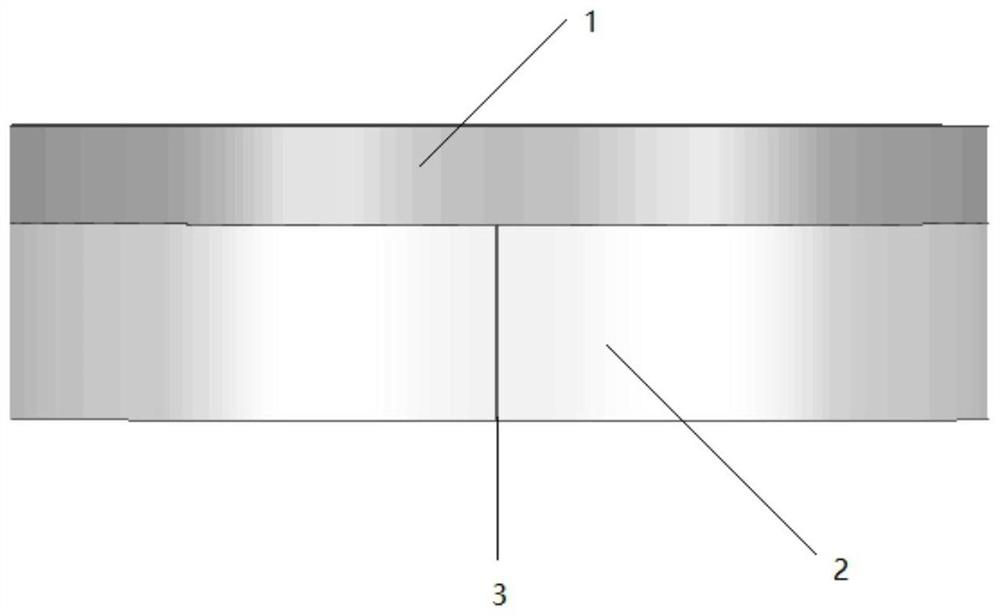

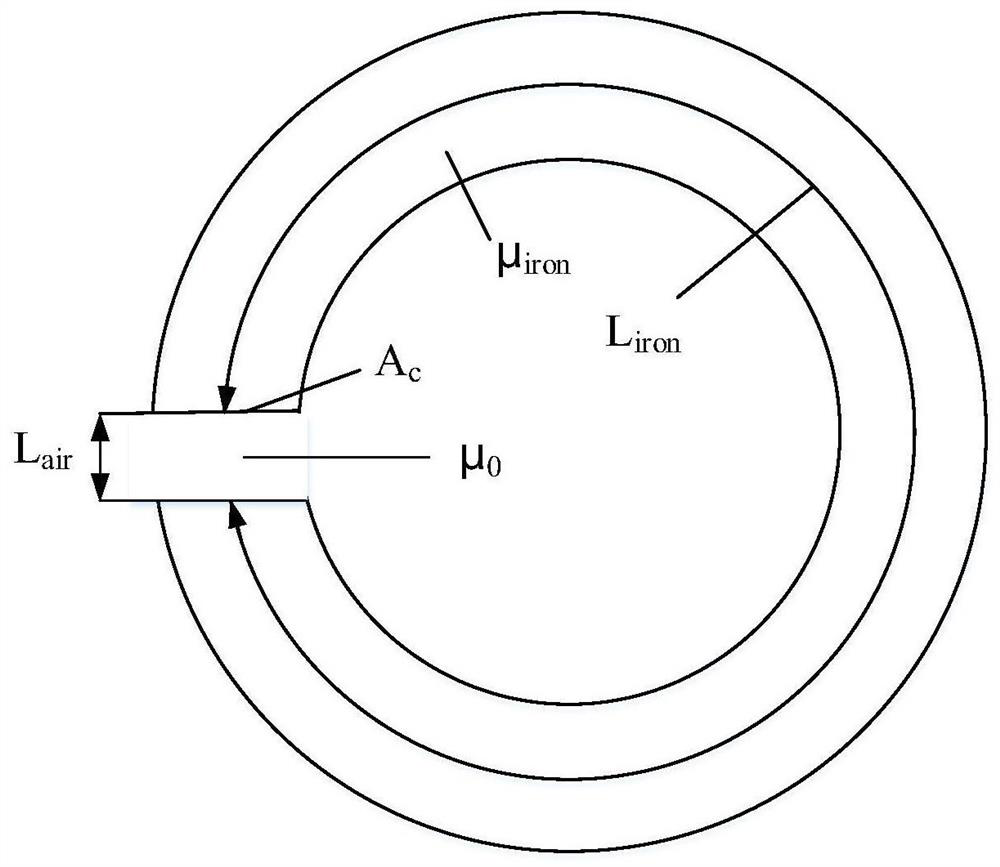

[0145] The double skeleton common winding current transformer structure includes an ultra-microcrystalline iron core 1 and a silicon steel sheet iron core 2, the ultra-microcrystalline iron core 1 is a closed iron core, and an air gap 3 is opened on the silicon steel sheet iron core 2.

[0146] The ultra-microcrystalline iron core 1 and the silicon steel sheet iron core 2 are arranged side by side and stacked together.

[0147] The inner and outer radii of the ultra-microcrystalline iron core 1 and the silicon steel sheet iron core 2 are the same. When the windings are co-wound, the generation of excess edge magnetic flux can be avoided, which will affect the performance of the current transformer.

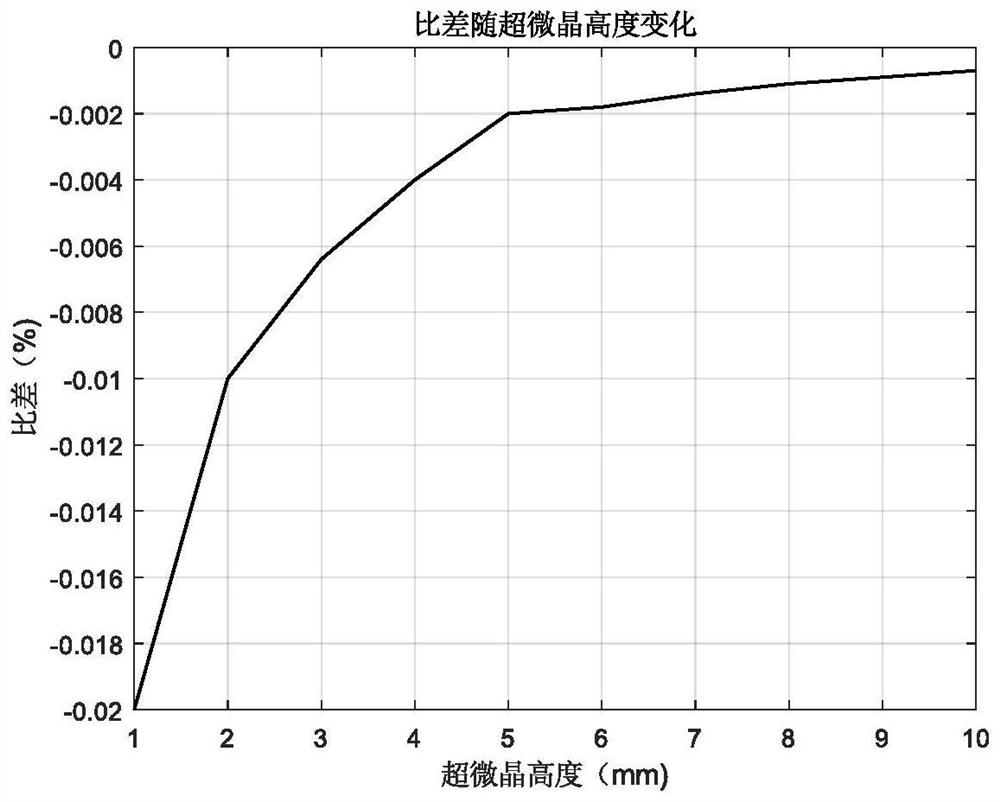

[0148] The height of the ultra-microcrystalline iron core 1 is h1, the height of the silicon steel sheet iron core 2 is h2, and the length of the air gap 3 is L δ , the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com