Carbon capture system based on capacitive deionization technology

A capacitive deionization and carbon capture technology, applied in the field of carbon capture systems, can solve the problems of low capacitor power, increased energy consumption, toxic and harmful amines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

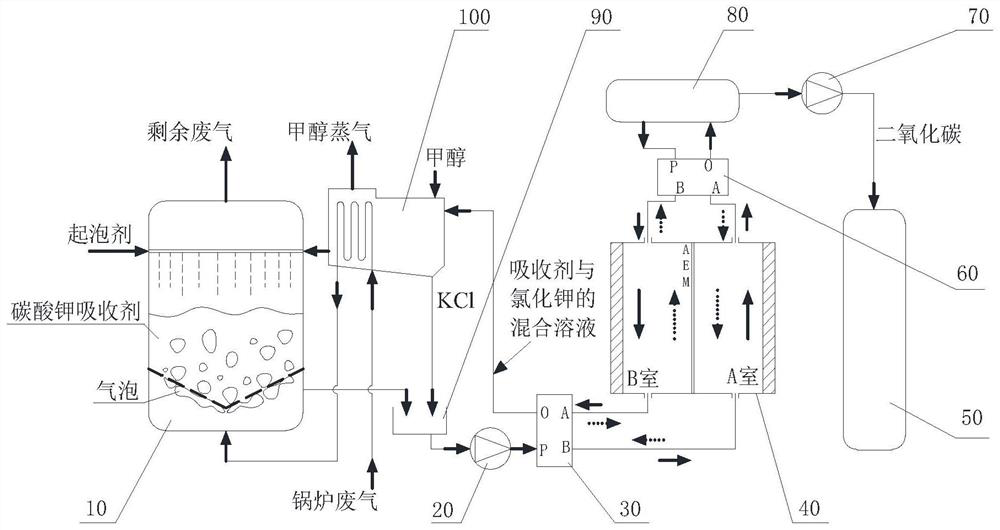

[0023] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

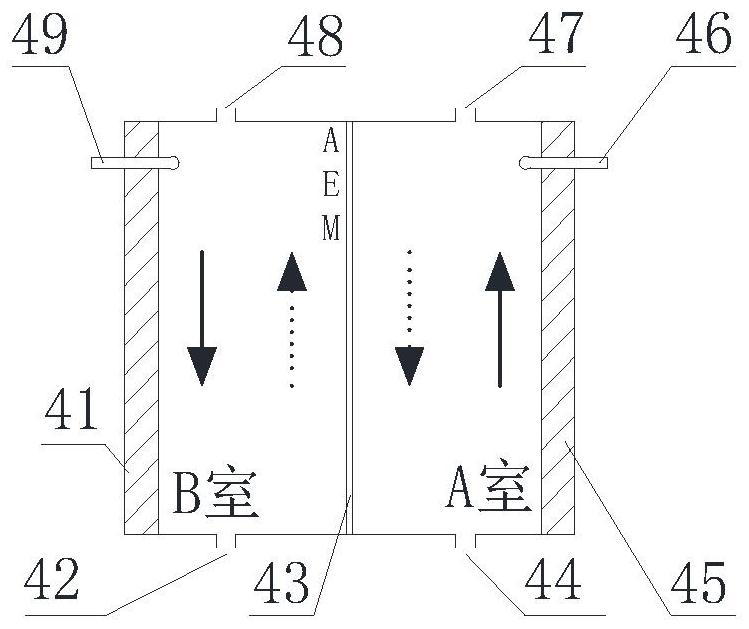

[0024] like figure 1 As shown, the present invention includes an absorption chamber 10, a drive pump 20, a first solenoid valve 30, a capacitive deionization device 40, a storage tank 50, a second solenoid valve 60, a fan 70, a flash tank 80, a buffer chamber 90, a separation chamber 100.

[0025] The boiler exhaust gas inlet is connected to the coil inlet 162 of the separation chamber 100, the coil outlet 161 of the separation chamber 100 is connected to the exhaust gas inlet 12 at the bottom of the absorption chamber 10, the top of the absorption chamber 10 is provided with the remaining exhaust gas outlet 16, and the outlet 170 of the separation chamber 100 is connected to the absorption chamber 10 side inlet 15 is communicated. A foaming agent inlet 17 is provided above the foaming agent inlet and the absorption chamber 10, the absorbent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com