Wafer cleaning device for liquid protection

A technology for cleaning devices and wafers, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as damage to drive and transmission structures, achieve smooth rotation, and improve waterproof effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

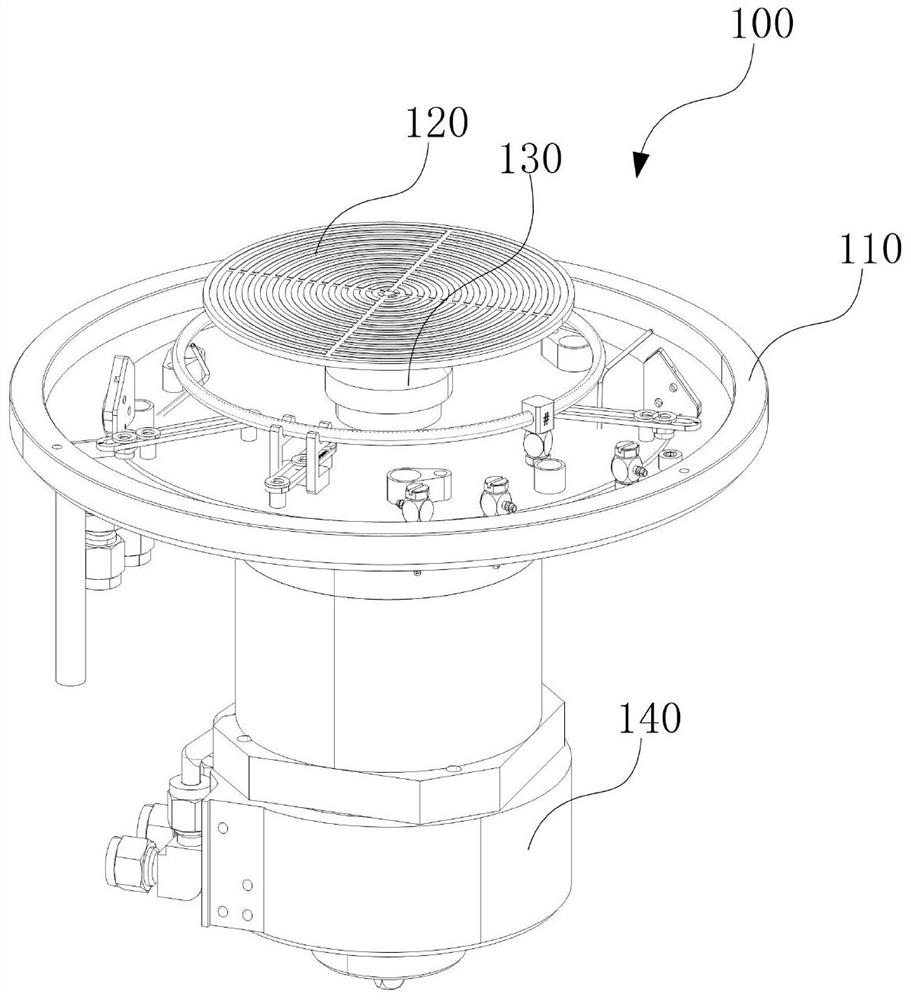

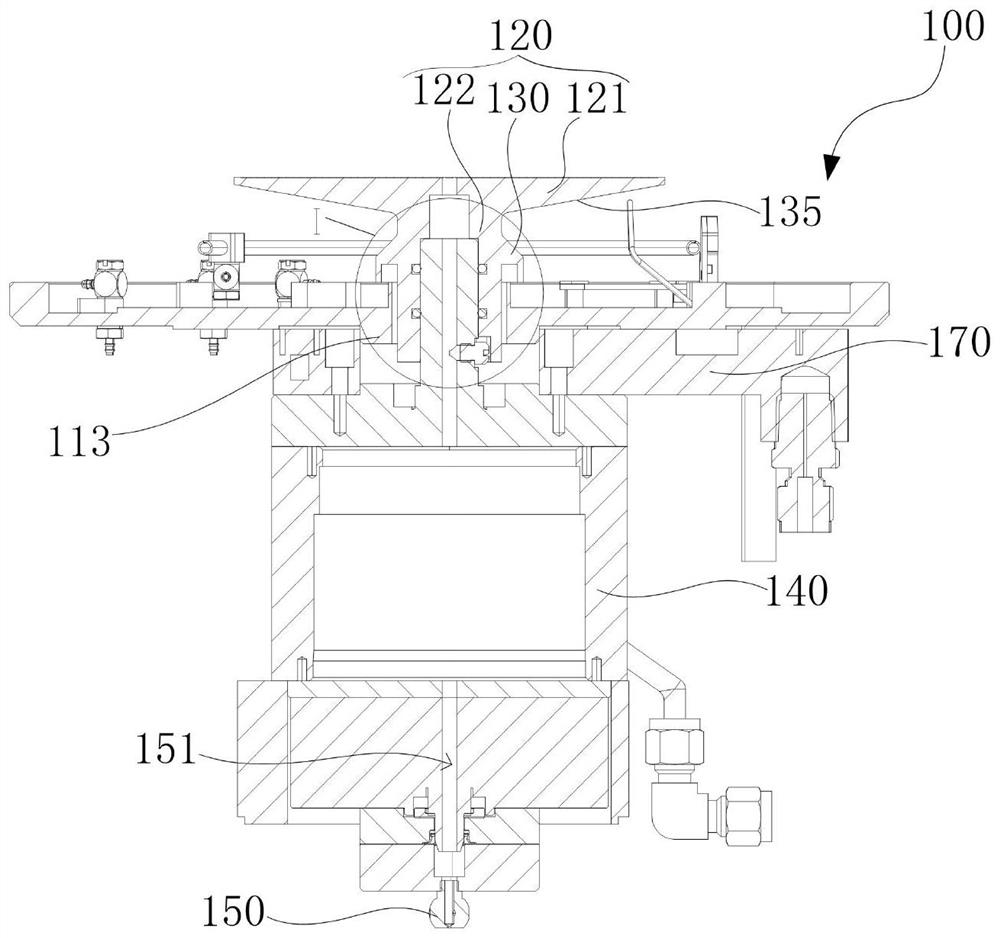

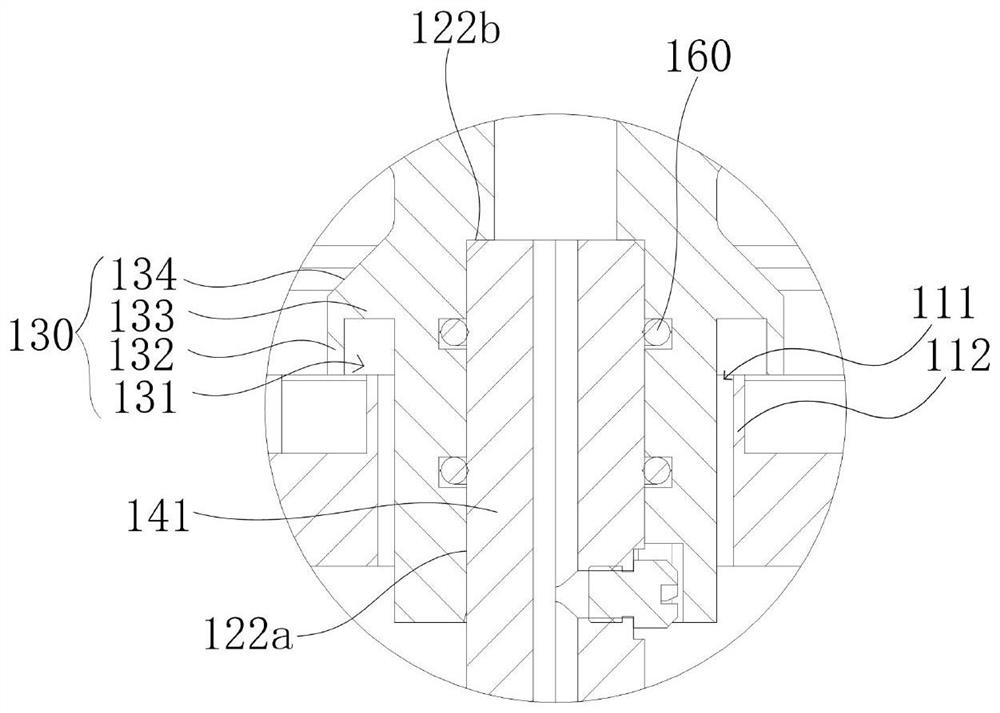

[0039] see Figure 1-3The first embodiment of the present invention provides a wafer cleaning device 100 for liquid protection, including: a mounting plate 110, the mounting plate 110 includes a mounting plate body, a mounting hole 111 opened in the center of the mounting plate body, and a mounting plate The baffle plate 112 on the top surface of the disc body and surrounding the installation hole 111; the wafer support portion 120, the wafer support portion 120 includes a wafer support table 121, a support column 122 and a liquid blocking cover 130, the support column 122 is arranged in the installation hole 111, and the wafer support table 121 is connected to the top of the support column 122 , the liquid blocking cover 130 surrounds the supporting column 122 , and the liquid blocking cover 130 covers the mounting hole 111 .

[0040] In this embodiment, the mounting plate 110 is used for accommodating the nozzles and other devices required for cleaning, and at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com