Pipe fitting forming method and device for improving magnetic field distribution of trapezoidal magnetic collector through convex pieces

A technology of magnetic field distribution and magnetic collector, which is applied in the field of electromagnetic forming control of pipe fittings, can solve problems such as uneven distribution of electromagnetic force, reduction of circumferential uniformity of electromagnetic forming, and weak electromagnetic force, so as to facilitate large-scale promotion and use and improve electromagnetic field distribution Unbalanced, easy-to-produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

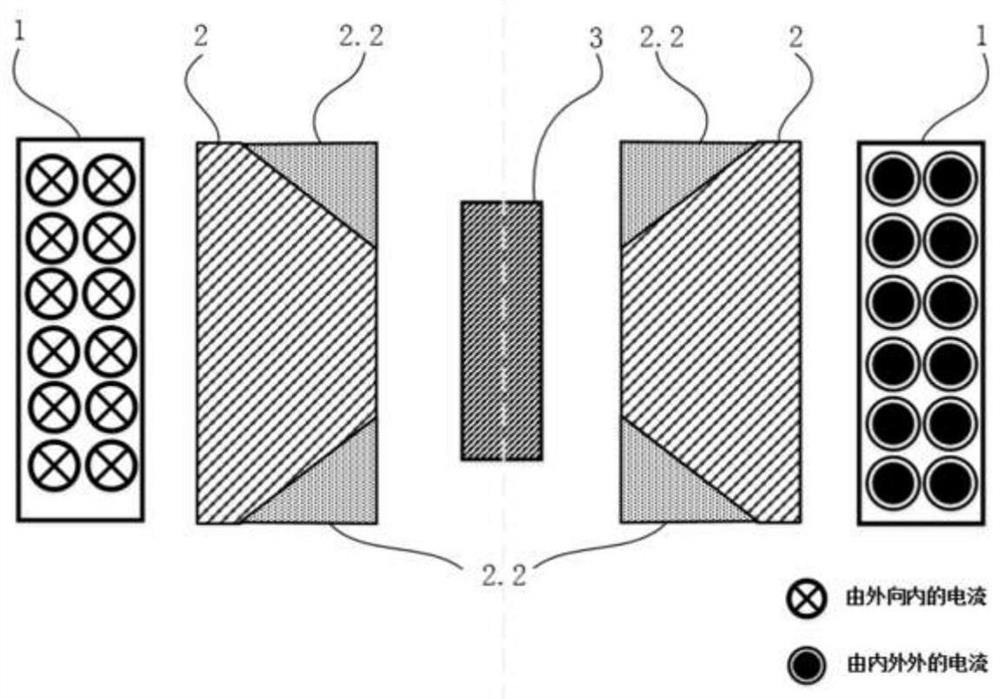

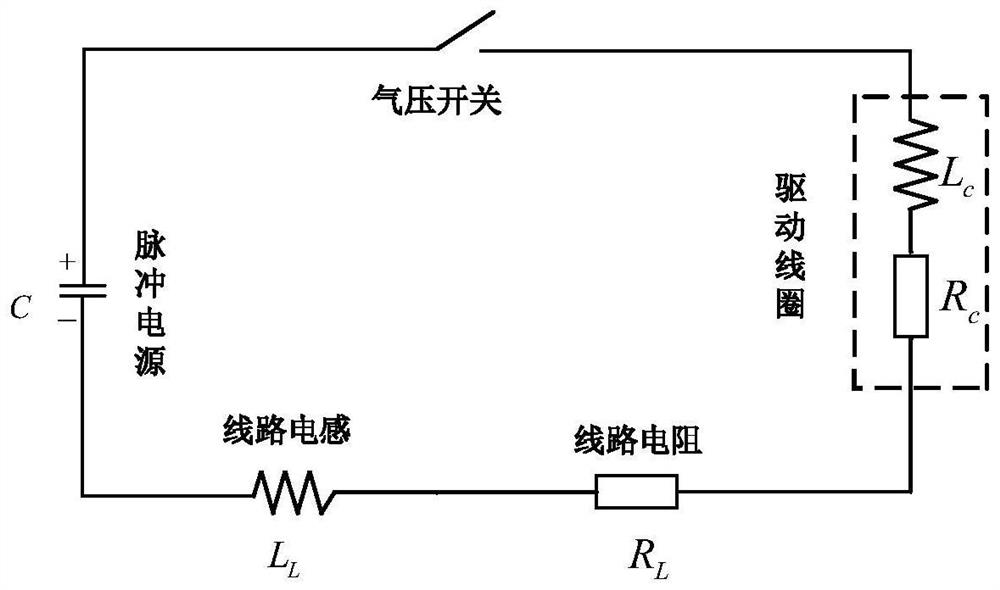

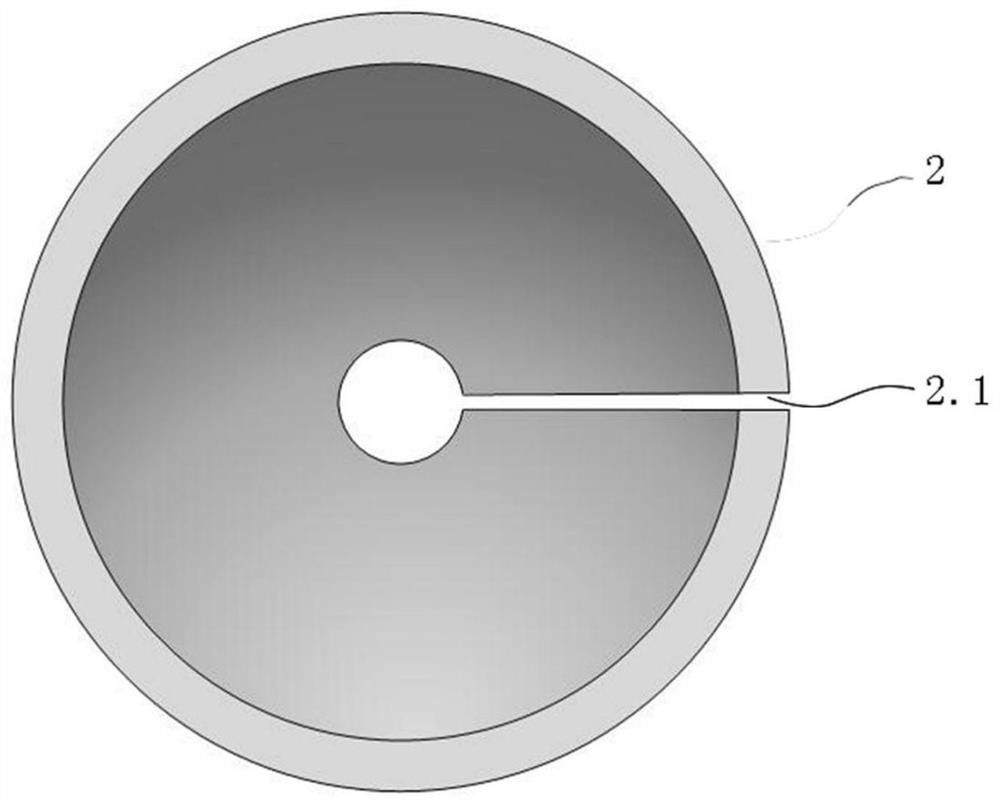

[0034] image 3 It is a magnetic collector of the existing technology. The magnetic device is a trapezoidal ring, and there is a very narrow seam with a ring; the height of the outer wall of the ring is far greater than the height of the inner wall. The capacitor power supply is powered on the driving coil to generate counter -timing pipe current. According to the law of electromagnetic induction, the inner wall of the magnetic device will generate a clockwise sensing current; at the same time, due to the gap in the magnetic collector, the induction current cannot form a closed loop on the inner wall; therefore, the inductive current encounters encounters When the gap is the gap, it will flow along the gap to the outer wall of the magnetic device, and form a reverse -clockic induction current on its outer wall. The induction current of the inner wall of the magnetic device is used as the source of incentives for the workpiece, and the induction current is generated within the work...

Embodiment 2

[0050] The pipe forming method of the embodiment is the same as the embodiment.

[0051] The number of cashmers of the trapezoidal magnetic 2 2.2 of the embodiment of the embodiment is 2 pairs, the angle of the adjacent convex tablet 2.2 is 120 °, and the angle of the disconnected seam 2.1 and the adjacent bulk 2.2 is 120 °, such as 120 °, such as Figure 5A As well as 5b Show.

Embodiment 3

[0053] The pipe forming method of the embodiment is the same as the embodiment.

[0054] The number of convex 2.2 of the trapezoidal magnetic 2 2.2 of the embodiment is 1 pair, and the angle of the convex tablet 2.2 and the broken seam 2.1 is 180 °, such as Figure 6A As well as 6b Show.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com