Design scheme and preparation method of composite material wing for micro ornithopter

A technology of flapping wing aircraft and composite materials, which is applied in the field of aircraft design and manufacturing, can solve the problems of poor processing consistency, poor aerodynamic performance, and short service life, and achieve the effects of good aerodynamic performance, good processing consistency, and strong designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention is further described below in conjunction with the accompanying drawings and examples.

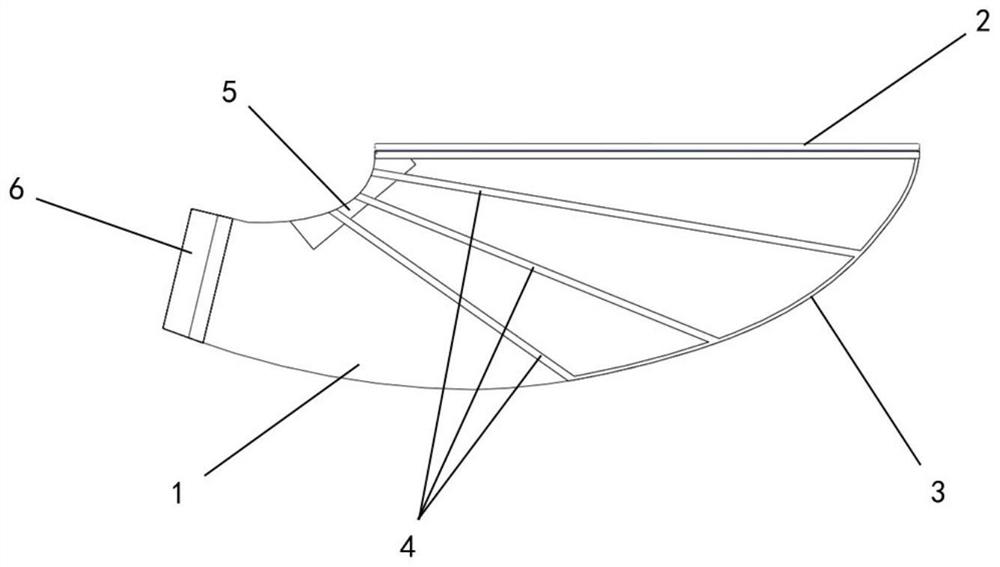

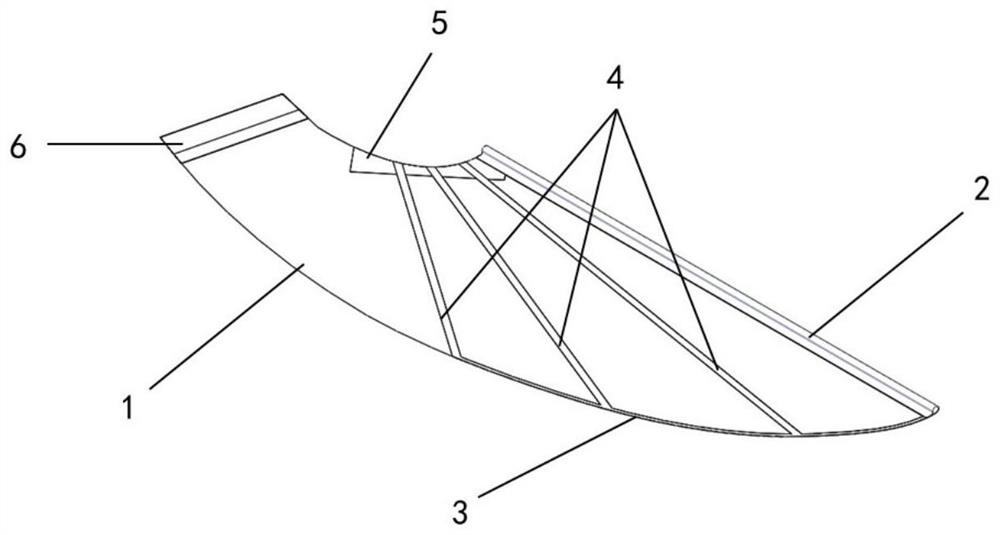

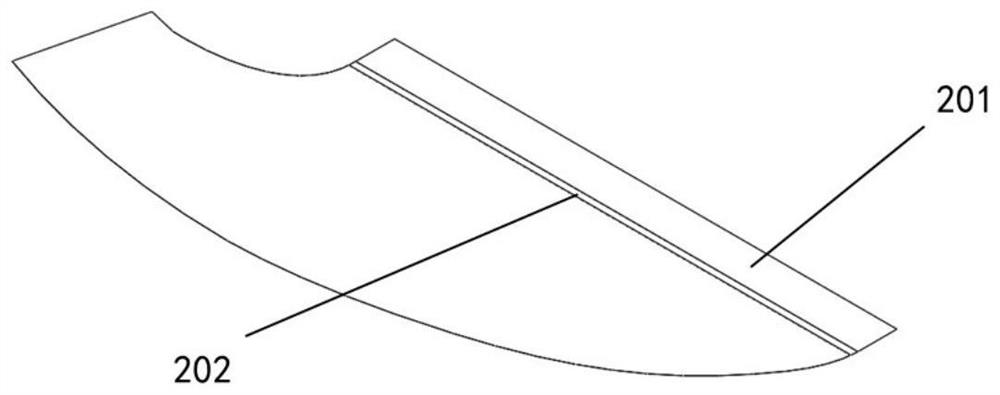

[0062] The present invention is a composite material wing for a micro flapping aircraft, which is composed of a wing membrane 1, a sleeve 2, a wing vein (including a secondary wing vein 3 and a main wing vein 4), an adhesive tape 5 for protecting the wing membrane, and a fixed compound. Material wing tape 6 (as figure 1 and figure 2 The difference from the current design of the wing used in the micro flapping-wing aircraft is: the design of the wing veins (including the secondary wing vein 3 and the main wing vein 4) has been changed, and the tape used to protect the wing membrane has been added. 5 designs.

[0063] The design of the wing veins (including the secondary wing veins 3 and the main wing veins 4) is that the wing veins (including the secondary wing veins 3 and the main wing veins 4) of the composite wing are divided into the secondary wing veins ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com