Semi-steel tire steel wire ring winding and attaching method

A technology of bead rings and tires, which is applied in the field of tire production, can solve the problems of large area occupied by the bead ring storage area, frequent batch quality production accidents, and high labor intensity of workers, so as to eliminate batch production accidents, realize full automation, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

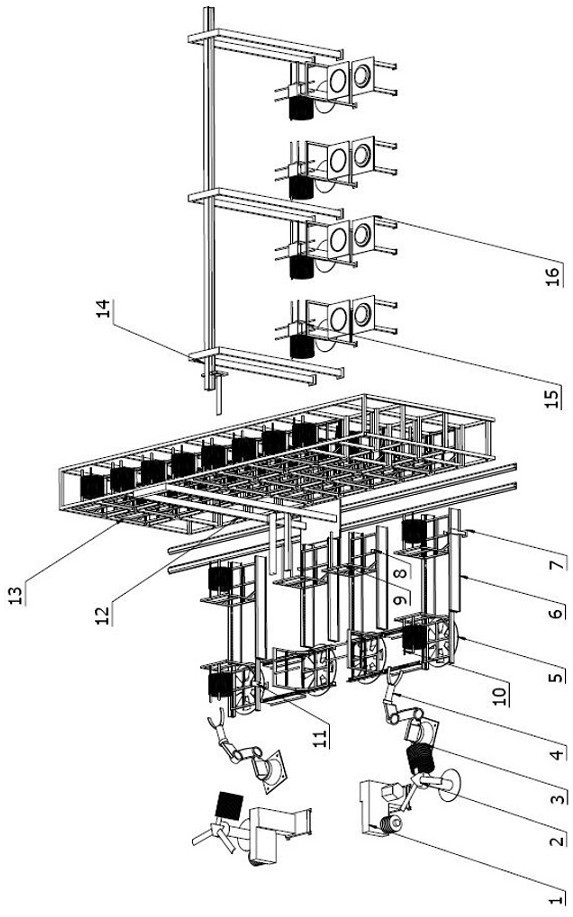

[0009] In the figure, the present invention is provided with a three-dimensional storehouse 13, a stacker 12 is installed in the three-dimensional storehouse 13, the entrance of the three-dimensional storehouse 13 is connected to the output end of the chain machine 6, and a first RFID reader is installed at the entrance of the three-dimensional storehouse 13 Device 7, the input end of the chain machine 6 is connected with the outlet of the turntable 5, a tooling car is placed on the turntable 5, an RFID tag 8 is installed on the tooling car, and a second RFID reading device 11 is installed at the exit position of the turntable 5. A joint robot 4 is arranged at the entrance, and a traveler temporary storage rack 2 is installed within the grasping range of the joint robot 4. The traveler temporary storage rack 2 is located at the output port of the traveler winding machine 1, and the exit position of the three-dimensional library 13 is provided with The truss 14 is provided with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap