Marine anti-explosion watertight cabin door based on lightweight design

A lightweight design, watertight technology, applied in the direction of watertight door arrangement, door leaf, sealing device, etc., can solve problems such as unfavorable hatch door, coordinated design of door frame and bulkhead, loss of opening and closing ability, and heavy quality, so as to improve explosion-proof Performance, direct flyout prevention, and safety enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

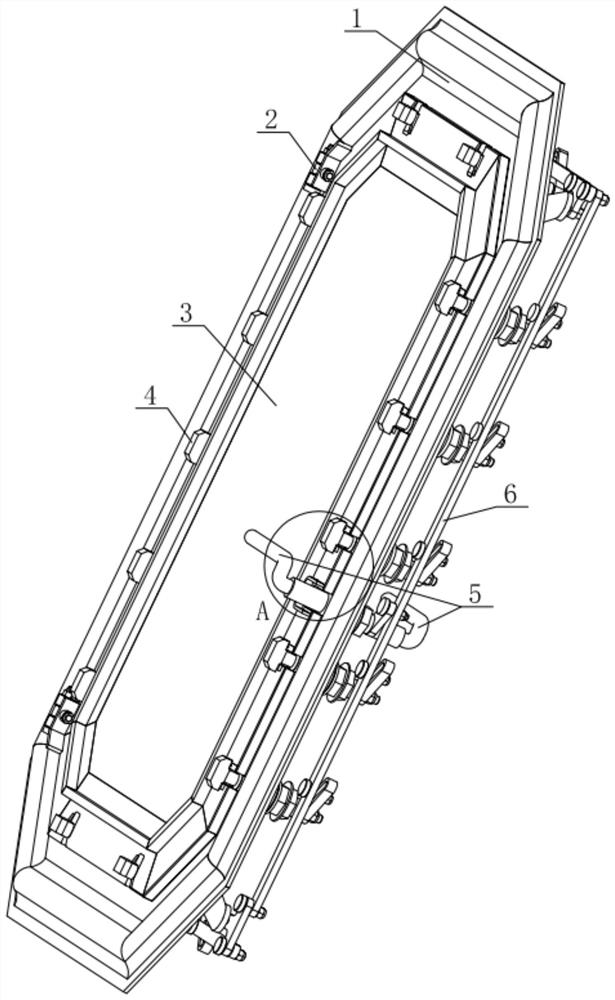

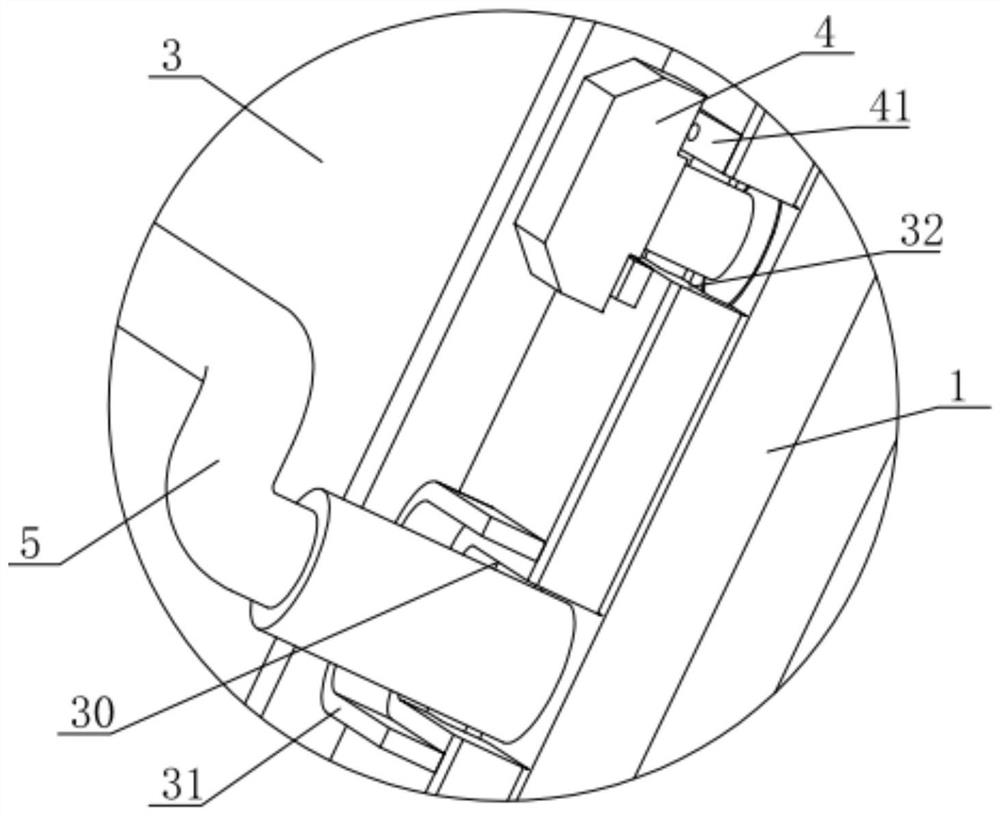

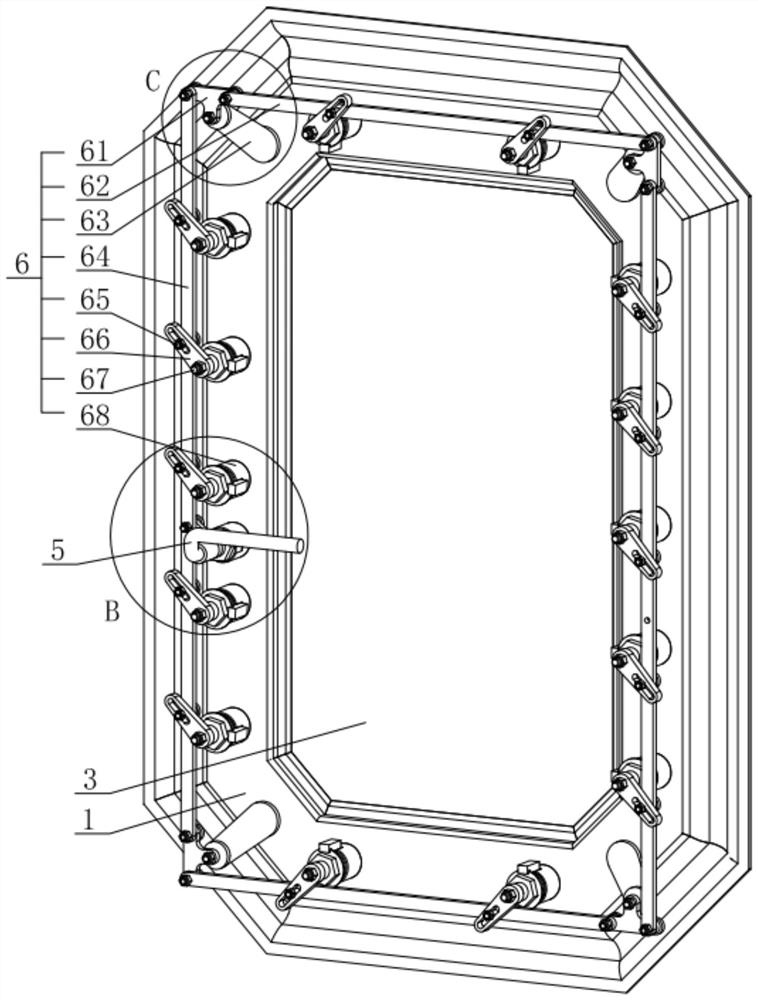

[0044] like figure 1 , figure 2 , Figure 9 and Figure 10 As shown, a marine explosion-proof watertight hatch based on a lightweight design in this embodiment includes a door frame 1 whose outer edge is fixedly installed with the bulkhead 7 along the circumferential direction. 1. A plurality of locking blocks 4 are installed on the inner edge of the side at intervals along the circumferential direction, and the edge of the door leaf 3 is provided with an opening groove 32 corresponding to the locking blocks 4 one-to-one and passing through the thickness direction along the circumferential direction; When the leaf 3 is attached to the door frame 1 , the end of the locking block 4 passes through the opening slot 32 in the direction of the door leaf 3 ; it also includes a linkage mechanism 6 that drives the plurality of locking blocks 4 to rotate sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com