Sealing structure for bearing cavity of turbine rotor of core engine

A technology of turbine rotor and core engine, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of core engine performance parameter interference, reduce stability and reliability, difficult processing and installation, and achieve simple and convenient processing. , The effect of reducing the change of the original structure and reducing the difficulty of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

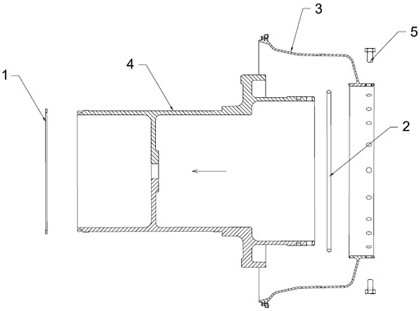

[0036] The core machine mainly includes high-pressure compressor components, combustion chamber and high-pressure turbine components, which work at extremely high temperatures and bear huge loads. When the gas turbine core machine test is performed, the turbine components will often retain the high-pressure turbine rotor 8 and the turbine fulcrum frame 12, and remove the low-pressure turbine rotor 18. In the prior art, after the low-pressure turbine rotor 18 is disassembled, a method of connecting the modified low-pressure shaft barrel to the turbine fulcrum frame 12 is often used to simply process the core machine, and then start the core machine test. Many sealing structures and low-pressure bearings are retained. These complex structures reduce the stability and reliability of operation, and the core machine only has compressed air from a high-pressure compressor, and its internal bleed air pressure is much lower than that of the whole machine. Therefore, these sealing struc...

Embodiment 2

[0050] When the sealing structure is not used for the high-pressure turbine rotor 8 and the low-pressure turbine rotor 18 described in Embodiment 1, but is applied to core machines of other types or structures for sealing, the sealing structure can also be used for sealing.

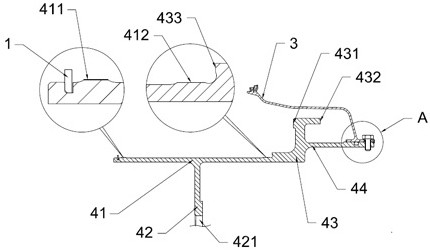

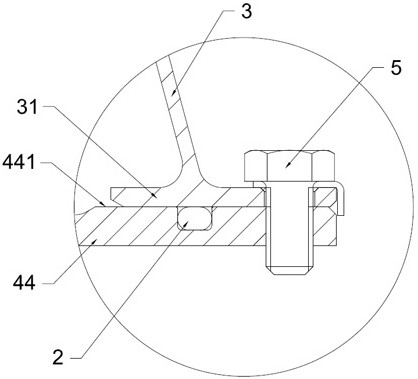

[0051] Specifically, the sealing structure in this embodiment includes a rear shaft section 44, an installation disk portion 43 and a front shaft section 41; the rear shaft section 44, the installation disk portion 43 and the front shaft section 41 extend from the rear to the rear of the core machine. The front side of the outer edge of the mounting disc portion 43 has a front pressing surface 431; the oil cavity sealing bushing 3 is in the shape of a cone ring, and the rear sides of the oil cavity sealing bushing 3 are respectively sealed and connected The rear shaft section 44 is formed with a second oil cavity 14 between the oil cavity sealing bushing 3, the sealing shaft barrel 4 and the original struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com