Cylindrical roller bearing and assembling method thereof

A technology of cylindrical roller bearings and rollers, applied in the field of cylindrical roller bearings and cylindrical roller bearing assembly, can solve the problems of high energy consumption, failure of sliding friction and wear of cylindrical roller bearings with large sliding ratio, and achieve energy consumption Low, small sliding friction, stable and reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

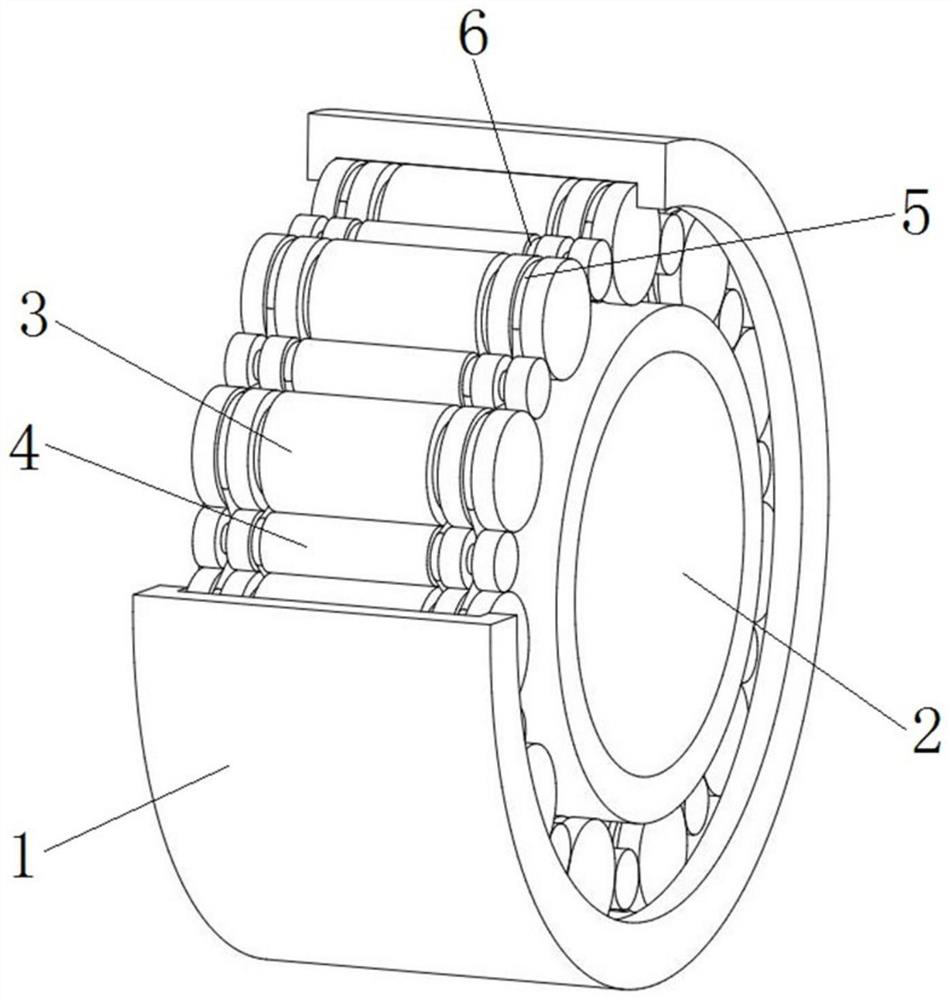

[0043] like figure 1 As shown, it includes an outer ring 1 , an inner ring 2 , a roller 3 , a spacer rod 4 and a tightening ring group, and the tightening ring group includes a first tightening ring 5 and a second tightening ring 6 .

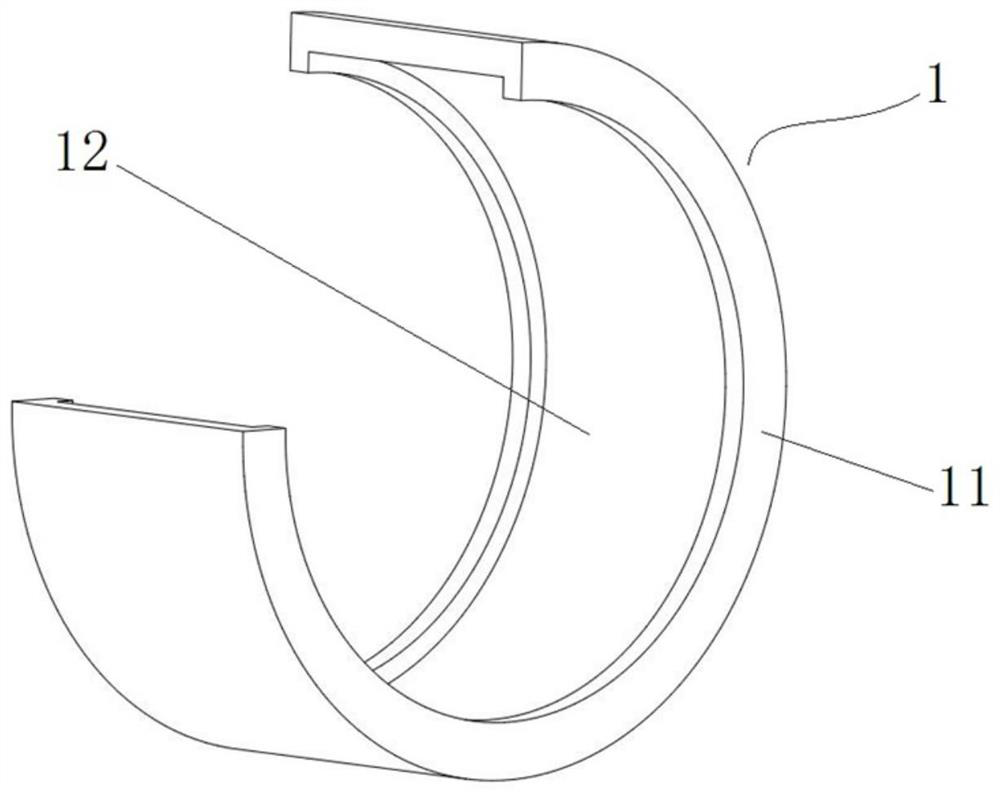

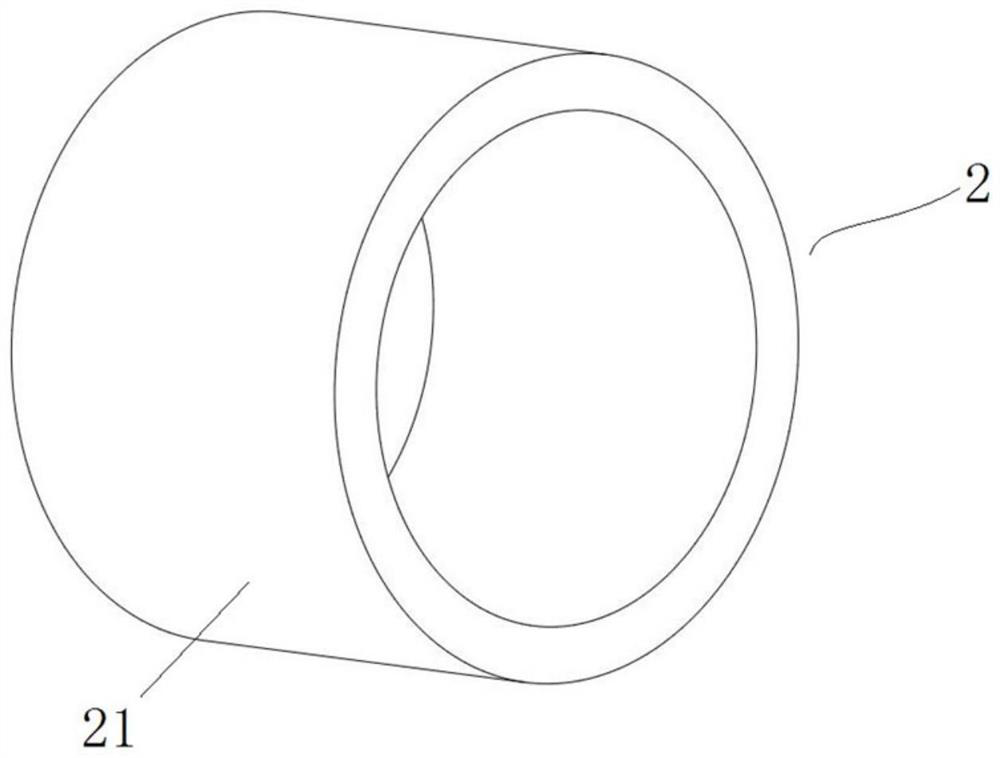

[0044] Part of the structure of outer ring 1 is as follows figure 2 As shown, the outer ring 1 is annular as a whole, and both axial ends of the outer ring 1 have flanges 11 that are folded radially inward. Outer raceway 12. The structure of inner ring 2 is as follows image 3 As shown, the inner ring 2 has a cylindrical shape, and its outer peripheral surface constitutes an inner raceway 21 that fits with the rollers 3 .

[0045] like Figure 4 As shown, the roller 3 is cylindrical, and the two axial ends of the roller 3 are provided with matching ring grooves for the roller hooping ring. Specifically, each matching ring groove for the roller hooping ring includes two ring grooves, one for the first roller The sub-ring grooves 31 and the ...

specific Embodiment 2

[0053] The specific embodiment 2 of the cylindrical roller bearing provided by the present invention is mainly different from the embodiment 1 in that: in the embodiment 1, both ends of the cylindrical roller bearing in the axial direction are provided with a hoop ring group. In this embodiment, only the clamping ring group is arranged in the middle of the cylindrical roller bearing.

specific Embodiment 3

[0054] The specific embodiment 3 of the cylindrical roller bearing provided by the present invention is mainly different from the embodiment 1 in that: in the embodiment 1, the tightening ring group is composed of two tightening rings. In this embodiment, the tightening ring group includes three tightening rings, and two adjacent ones of the three tightening rings are wound in opposite directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com