Torsional vibration absorber with excellent NVH (Noise Vibration and Harshness) performance, vibration absorber connecting structure and vehicle

A connection structure and vibration absorber technology, which is applied in the field of automobile transmission system, can solve the problems of insufficient NVH performance, high assembly difficulty, unfavorable limit, etc., and achieve the effect of improving NVH level, low cost and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

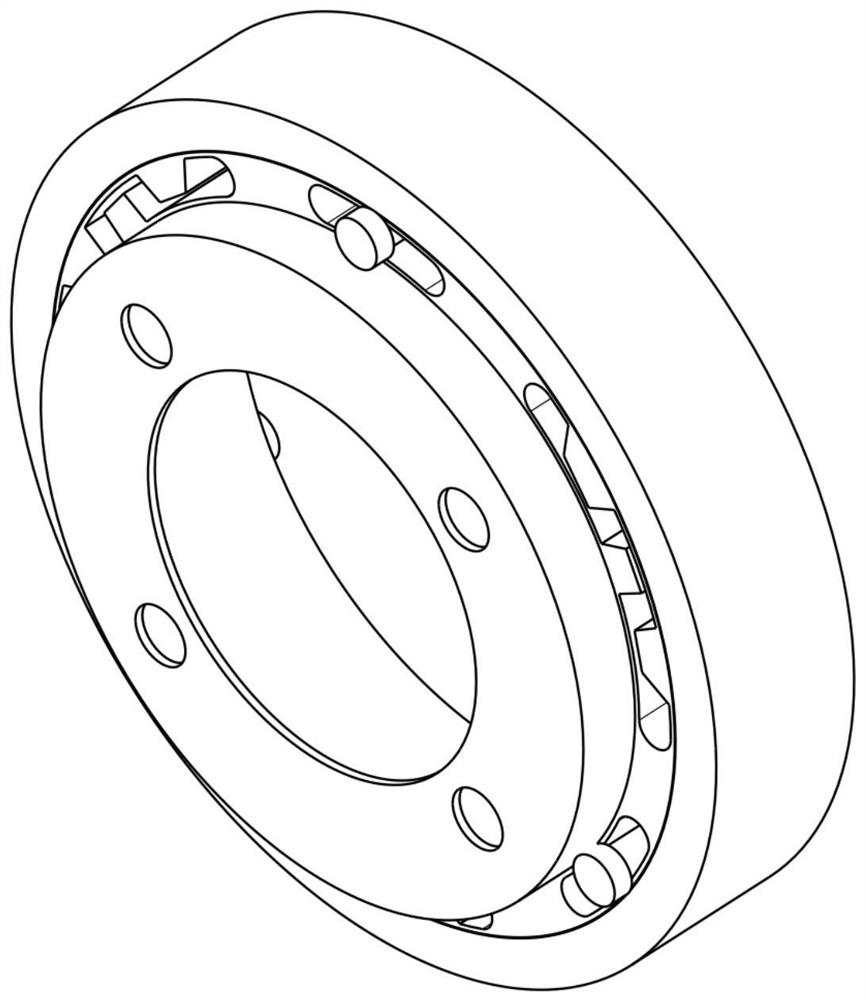

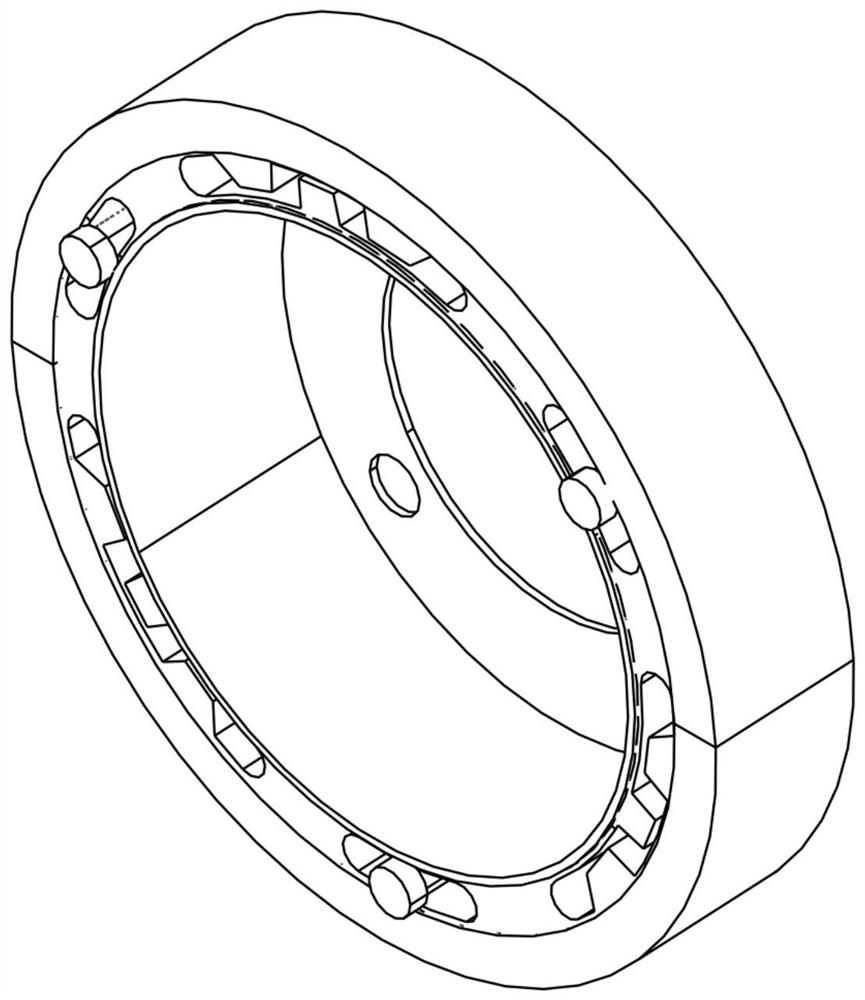

[0055] like Figure 1 to Figure 7As shown, a torsional vibration absorber with excellent NVH performance includes a flange 41, a rubber 42, a pin 43 and an inertia ring 44. A rubber 42 is vulcanized between the flange 41 and the inertia ring 44 to form a whole. The pin 43 is assembled in the axial through hole of the rubber 42, and the cross section of the axial through hole is a long circular arc. coaxial.

[0056] One end of the flange 41 protruding from the rubber 42 is provided with a flange positioning surface 411 . The flange positioning surface 411 is partially provided with four flange mounting holes 412 along the circumferential direction for mounting the flange fork 31 . The dimensional accuracy of the flange positioning surface 411 is at least H7, and the number of flange mounting holes 412 is the same as the number of flange fork mounting holes 311 .

[0057] The rubber 42 includes a main spring 421, and the main spring 421 is provided with a plurality of axial t...

Embodiment 2

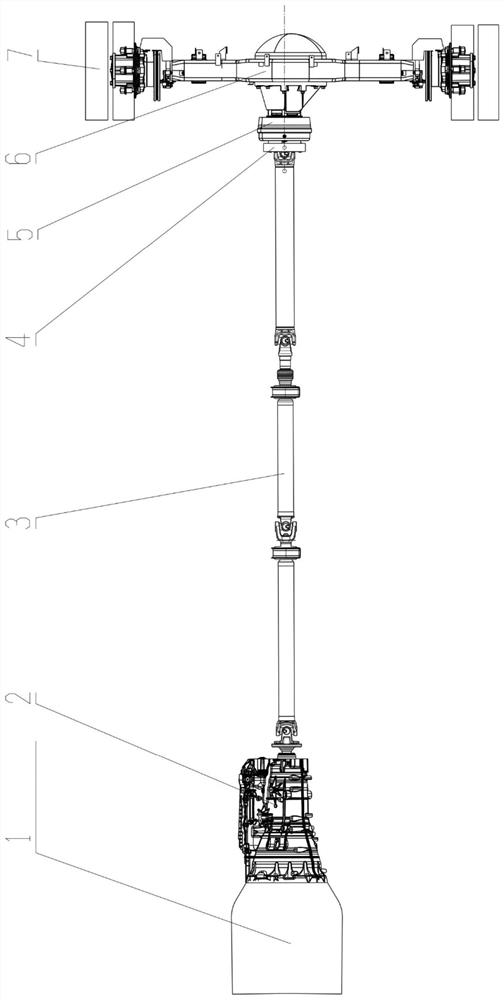

[0065] like figure 1 As shown, the power generated by the vehicle engine 1 is transmitted to the wheels 7 through the transmission 2 , the transmission shaft 3 , the torsional vibration absorber 4 , the parking brake 5 , and the rear axle 6 in sequence. Generally speaking, there is no parking brake 5 in the power train of a passenger car, and there is a parking brake 5 in the power train of a commercial vehicle; the engine 1 and the transmission 2, that is, the powertrain, have both vertical and horizontal positions.

[0066] This embodiment is a connection structure of a torsional vibration absorber, including a transmission shaft 3, a torsional vibration absorber 4, a parking brake 5, and a rear axle 6; 41 and the brake drum 51 of the parking brake 5 are connected by bolts, and the brake drum positioning surface 513 of the brake drum 51 is connected with the input flange 61 of the rear axle 6 .

[0067] like Figure 8 As shown, the flange fork 31 of the transmission shaft ...

Embodiment 3

[0076] A vehicle includes the torsional vibration absorber described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com