Shell pass exhaust and pollution discharge structure suitable for vertical shell-and-tube waste boiler heat exchanger

A shell-and-tube heat exchanger technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the local failure of the waste boiler heat exchanger, and can only be as close to the end of the tube sheet as possible. , can not be fully cooled, etc., to achieve the effect of good sewage effect, easy processing, and no difficulty in manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to specific embodiments and accompanying drawings.

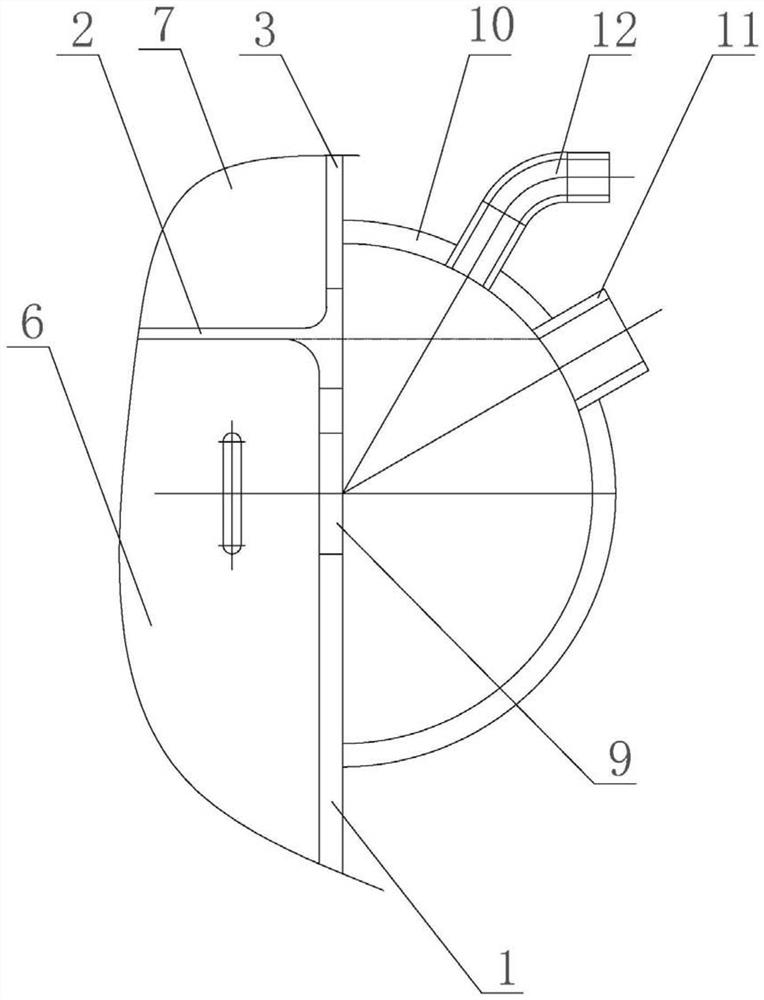

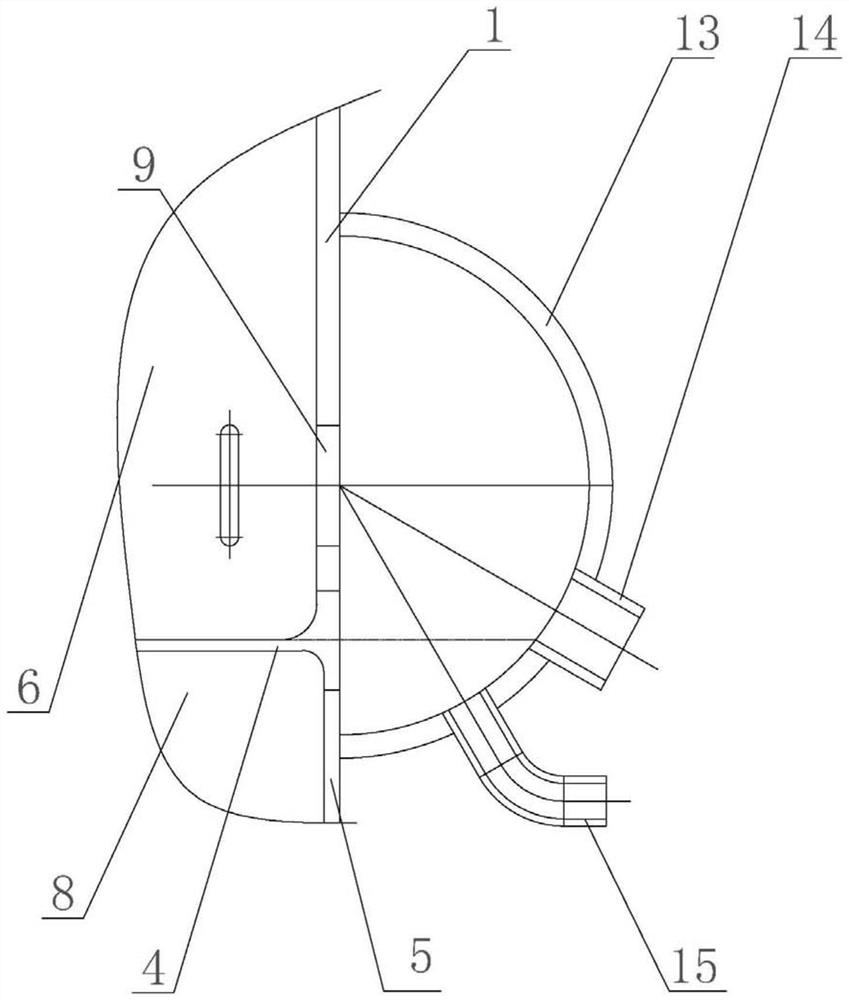

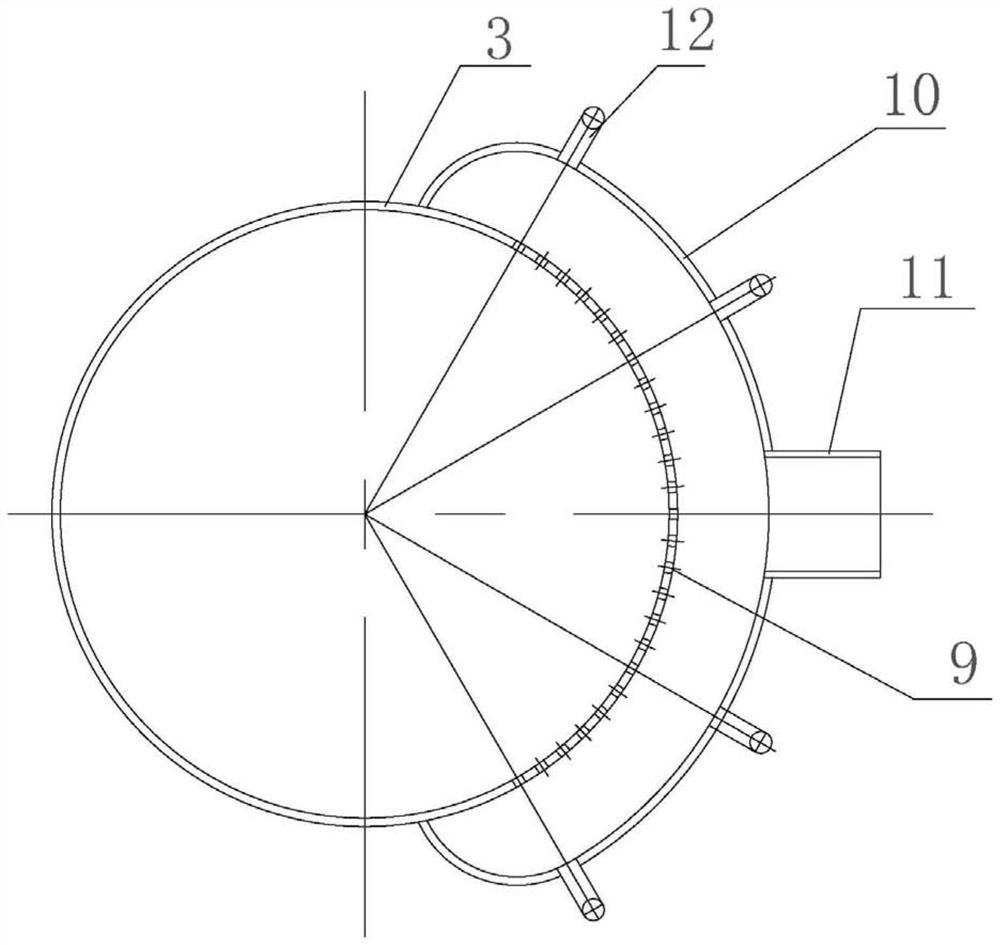

[0038] The shell-side exhaust and sewage discharge structure suitable for the vertical shell-and-tube waste boiler heat exchanger in this embodiment, such as figure 1 and figure 2 As shown, it includes a shell 1, an upper tube sheet 2, an upper tube box 3, a lower tube sheet 4, a lower tube box 5 and a plurality of heat exchange tubes (not shown in the figure), the shell 1 is a cylindrical body, the upper The tube sheet 2 and the lower tube sheet 4 are respectively fixed to the two ends of the shell 1 and together form a shell side space 6, the upper pipe box 3 is fixed to the upper tube sheet 2 and together form an upper pipe side space 7, and the lower pipe box 5 is fixed to the lower tube plate 4 and together form a lower tube side space 8 . A plurality of heat exchange tubes are located in the shell-side space 6 , and their upper ends are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com