Round tube axial stress measuring device and method based on torsional mode ultrasonic guided waves

An axial stress, ultrasonic guided wave technology, applied in the direction of measuring devices, measuring forces, instruments, etc., can solve the problems of inability to measure the axial stress of the circular tube, application limitations, and the influence of the surface quality of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

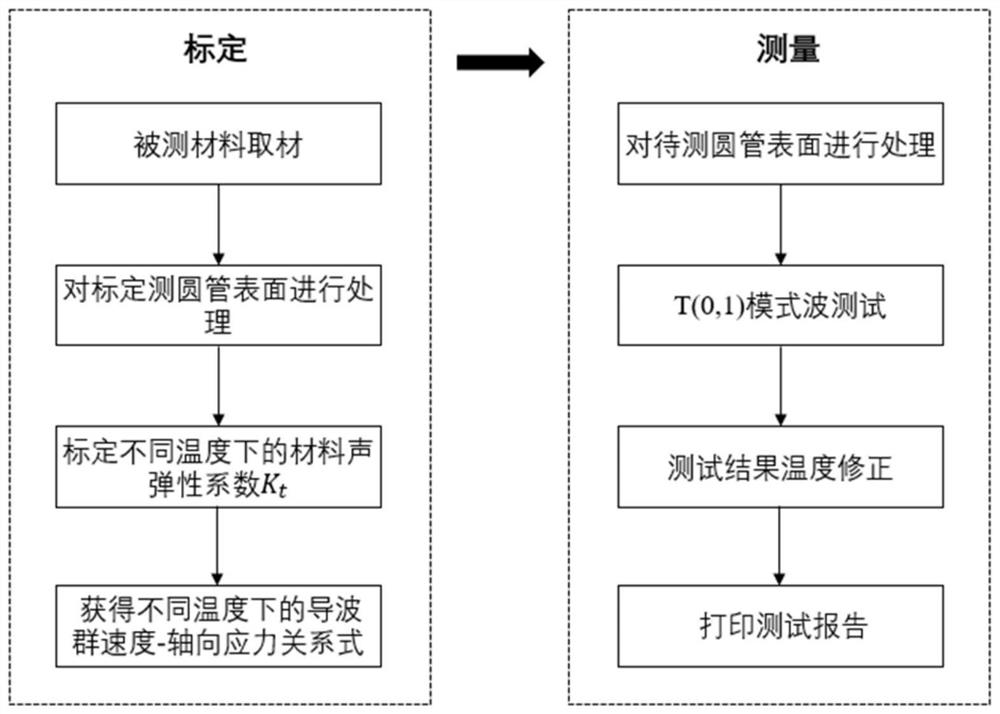

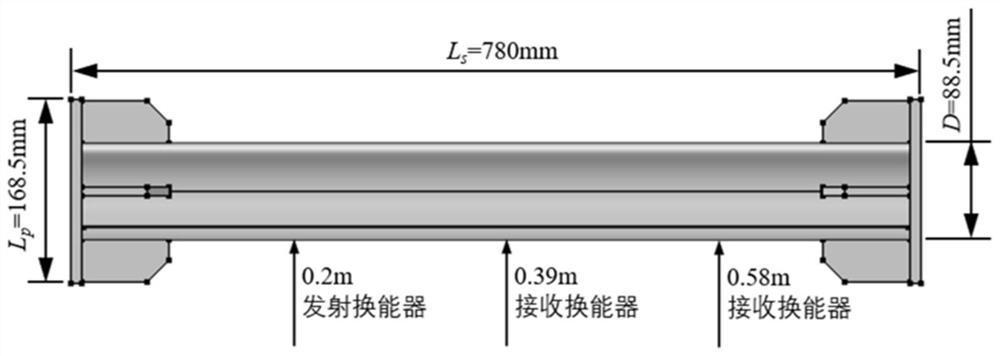

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings of the embodiments of the present invention. It should be noted that this embodiment is only a part of the embodiments of the present invention, and the technical parameters set in this embodiment are for reference only.

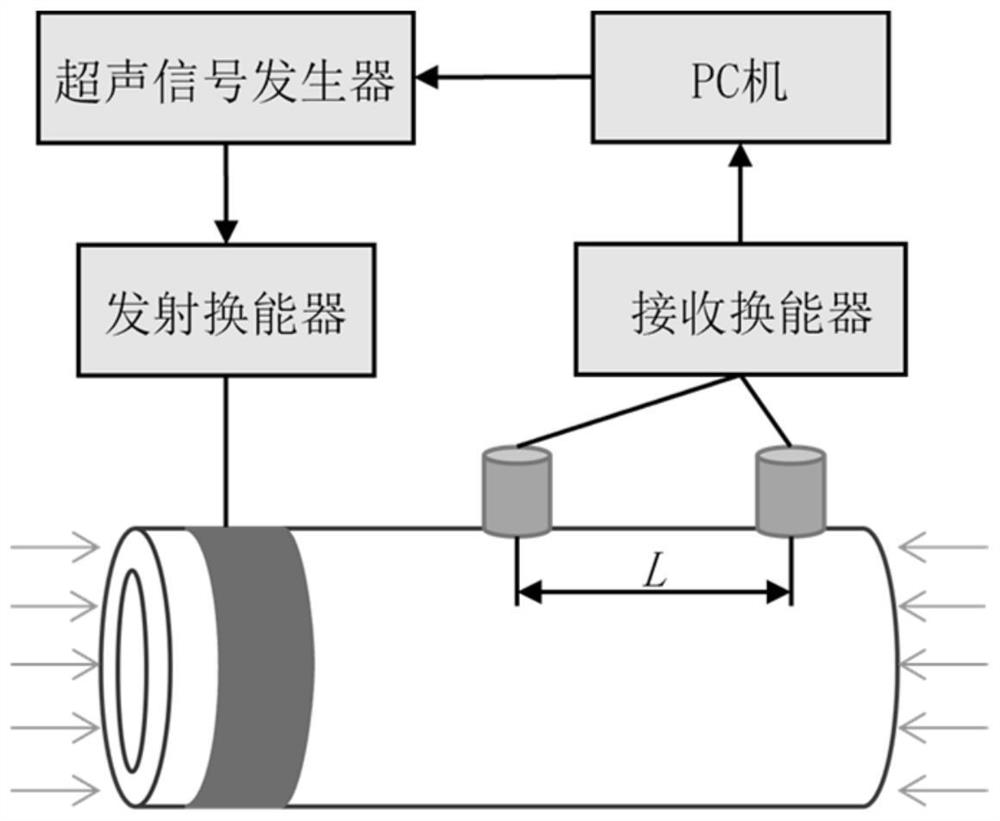

[0026] like figure 1 As shown, the present invention provides a device for measuring axial stress of a circular tube based on torsional mode ultrasonic guided waves, including a transmitting transducer, two receiving transducers, an ultrasonic generator and a PC;

[0027] The transmitting transducer is fixed at one end of the circular tube to be measured, and is used to excite the axially symmetric T(0,1) torsional mode ultrasonic guided wave transmitted along the axial direction of the circular tube and the particle vibration direction is tangential;

[0028] Two receiving transducers are fixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com