Method for measuring internal residual stress of thick plate welding part

A technology of internal residual stress and residual stress, which is used in measuring devices, force/torque/work measuring instruments, and process efficiency improvement. It can solve problems such as errors and complex welding processes, and achieve high efficiency and reliable measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make those skilled in the art better understand, the present invention will now be further described in detail with reference to specific examples.

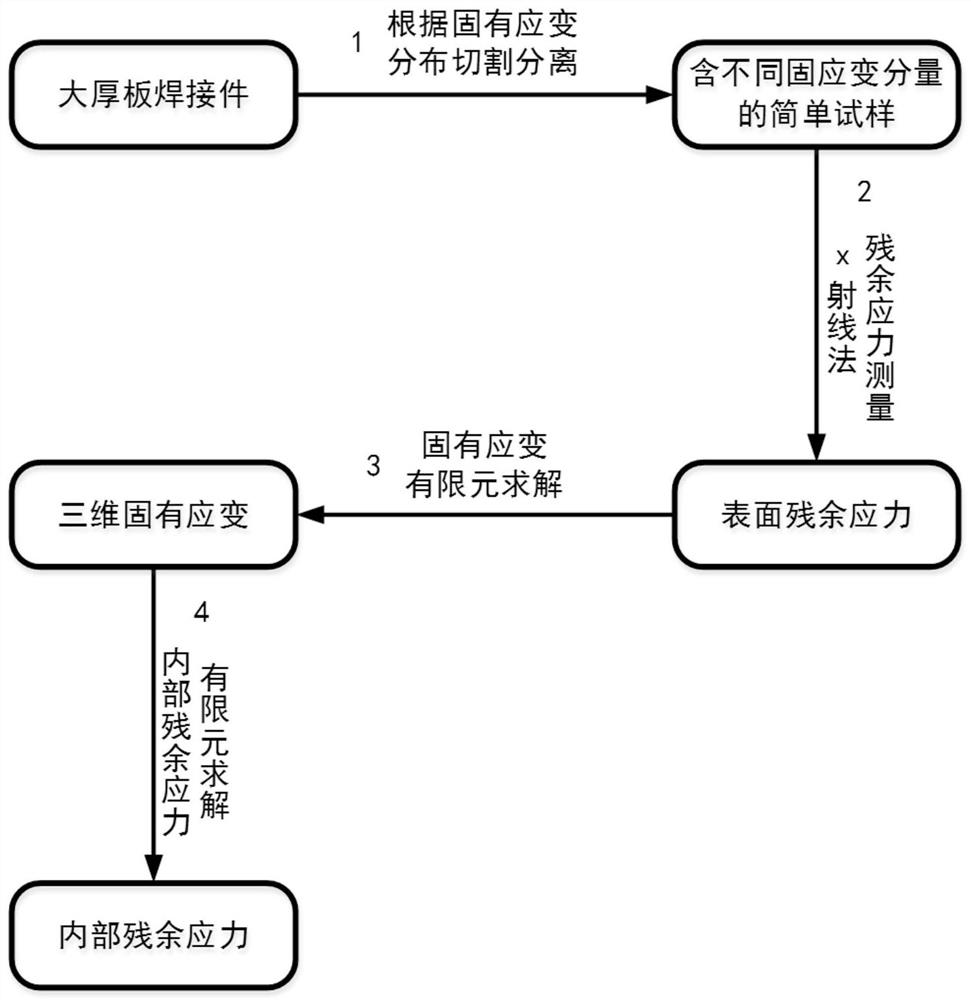

[0039] combine figure 1 , a method for measuring the internal residual stress of a thick plate weldment, through the combination of experimental test and finite element simulation, to measure the internal residual stress of the weldment.

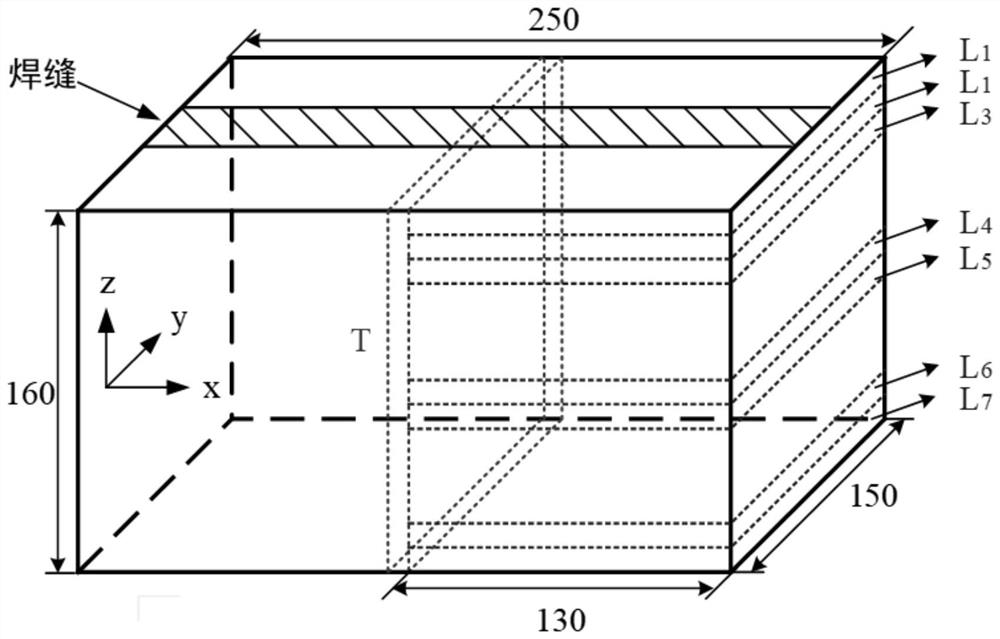

[0040] In this example, a TC4 titanium alloy thick plate with a size of 250mm*160mm*150mm forms a “nail-shaped” weld that is completely penetrated in the thickness direction, so that the internal stress first increases and then decreases along the thickness direction, and the weld length direction There is a condition of residual stress quasi-stable state, so the internal residual stress can be measured according to the following steps:

[0041] Step 1, Decomposition of Intrinsic Strain.

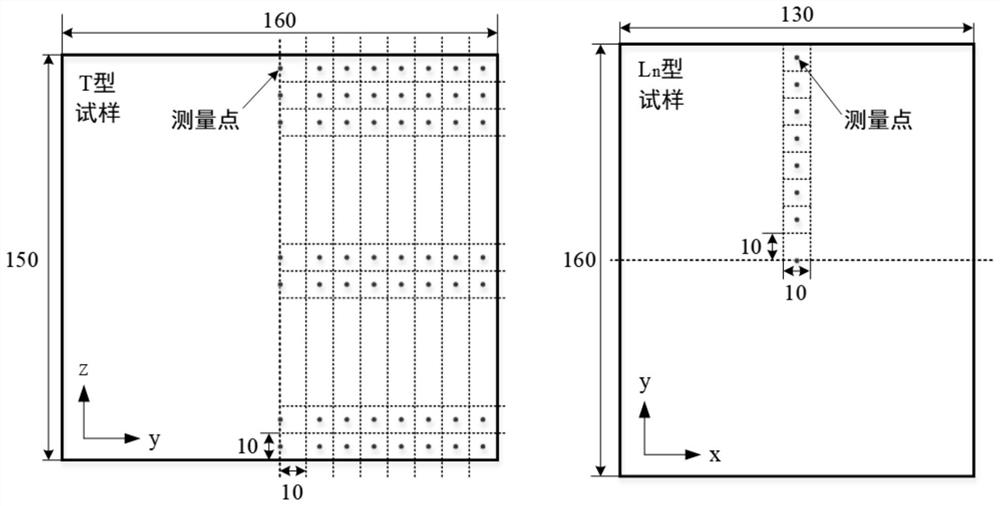

[0042] combine figure 2 , use wire cutting machine to weld TC4 titanium alloy thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com