Conductive adhesive dripping judgment method based on ultrasonic waves

An ultrasonic and conductive adhesive technology, applied in the re-radiation of sound waves, radio wave measurement systems, climate sustainability, etc., can solve the problems of dark spots and dark lines, LCD display defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

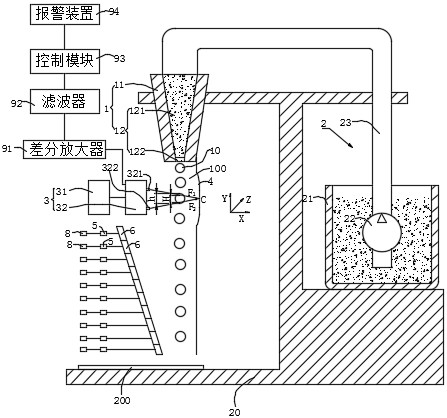

[0037] An ultrasonic-based conductive adhesive dripping judgment method is realized by an ultrasonic-based conductive adhesive dripping judgment system, such as figure 1 As shown, the ultrasonic-based conductive glue dropping judgment system includes a dripper 1, a conductive glue supply device 2, an ultrasonic generator 3, a reflector 4, a speed detection ultrasonic generator 5, a speed detection ultrasonic transducer 6, and a speed detection reflector. 7. Differential amplifier 91 , filter 92 , control module 93 and alarm device 94 .

[0038] like figure 1 As shown, the glue dispensing head 1 includes a main body 11, the main body 11 is in the shape of an inverted truncated cone, and a glue dispensing channel 12 is arranged in the main body 11. The lower end of the glue channel is a straight through hole 122 connecting the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com