Four-axis nanometer control system

A control system, nanotechnology, applied in the direction of general control system, control/regulation system, program control, etc., can solve the problems of large system interference, single static control, nanoscale precision motion process harmonic interference, etc., to reduce The amount of system interference, the realization of dynamic feedback, and the effect of avoiding harmonic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The invention will be further described below with reference to the accompanying drawings and specific embodiments.

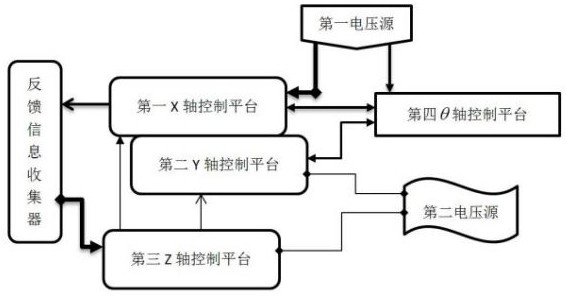

[0046] figure 1 It is a schematic diagram of the main structure of a four-axis nano-control system according to an embodiment of the present invention.

[0047] exist figure 1 , the four-axis nano-control system includes a four-axis motion control platform, and the four-axis motion control platform includes a first X-axis control platform, a second Y-axis control platform, a third Z-axis control platform, and a fourth θ-axis control platform platform.

[0048]Specifically, the first X-axis motion platform is used to control the acceleration and traction speed of the first target object in the X-axis direction;

[0049] The second Y-axis is mounted on the X-axis, and is used to adjust the distances between different multiple second target objects;

[0050] The third Z-axis control platform is used to control the movement of the third target object in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com