Various cohesiveness magnetic pad composition and making method thereof

A technology of bonding performance and vibration damping plate, which is applied in the direction of magnetic objects, magnetic materials, building structures, etc., can solve the problems of low vibration damping effect, low transmission loss of indoor noise isolation ability, etc., so as to improve vibration damping. performance, saving the cost of binder raw materials, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

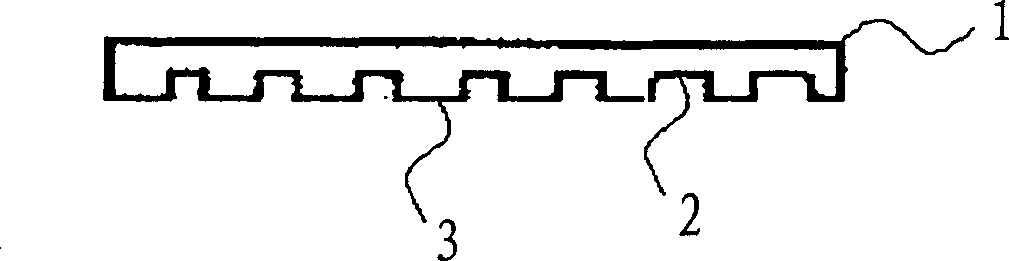

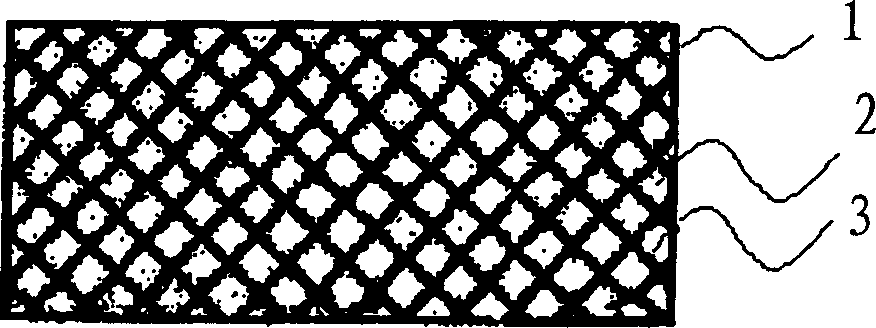

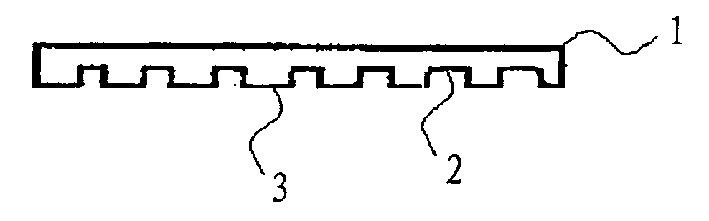

[0024] Manufacture the magnetic damping plate with the composition and content shown in Table 1, extrude it into a certain 2mm thick sheet, and press it to form a pattern. Then it is cooled by a cooling machine, magnetized by a magnetizer, and hot-melt adhesive is coated on the pattern, or it is not coated. Cut it into a size of 200×20mm with a press, and measure the damping coefficient. The damping coefficient is measured according to JASOM306-70 at the temperature of 20 and 40 ℃ respectively, and the results are shown in Table 1:

[0025] example

[0026] As mentioned above, the magnetic damping plate composition of the present invention does not require hot melt adhesives as in the past, and is bonded to the metal surface to be adhered by pitch and bonding resin in the magnetic damping plate without applying heat. Melting engineering can achieve the effect of saving binder raw material costs and engineering costs, and due to the improvement of vibration damping,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com