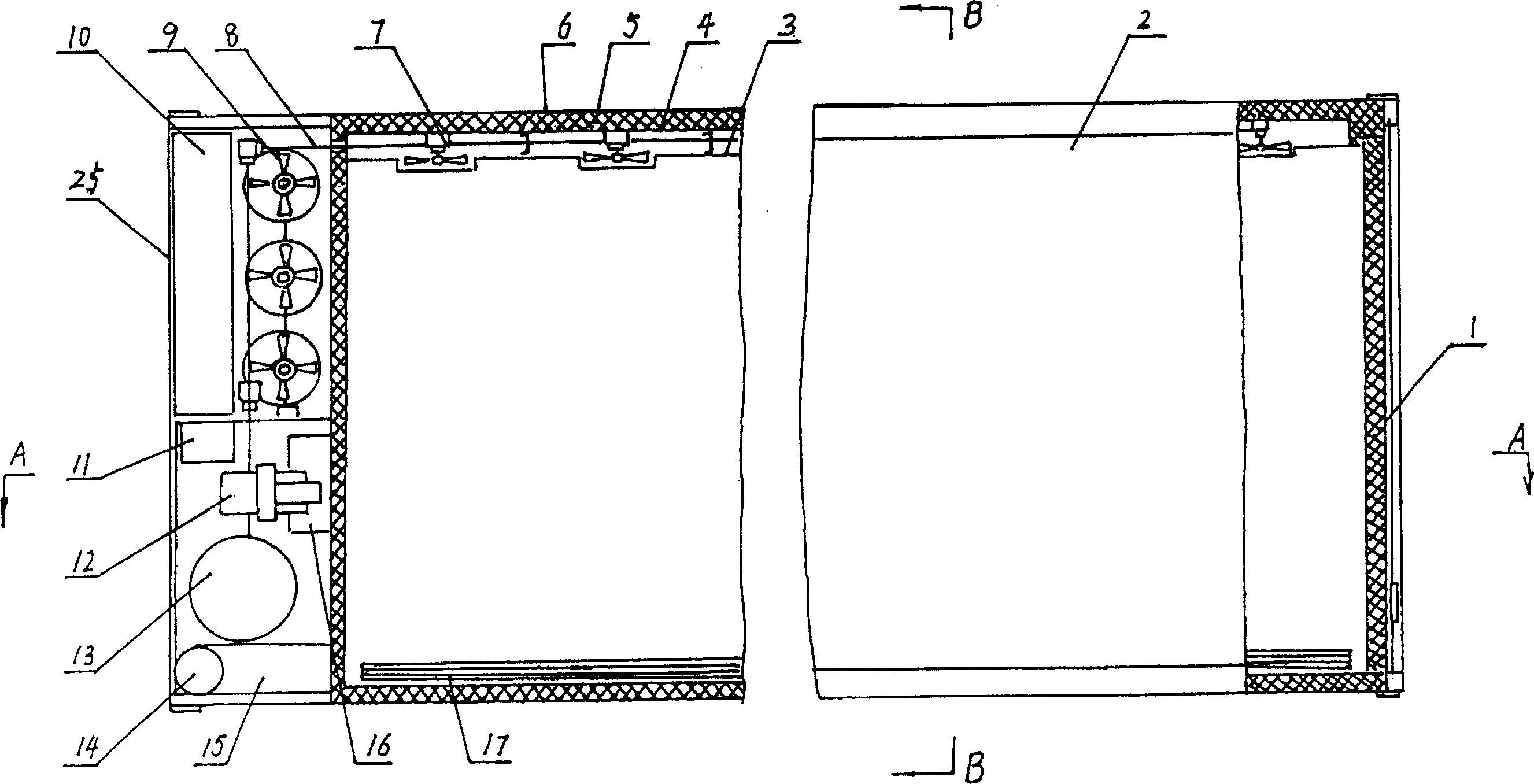

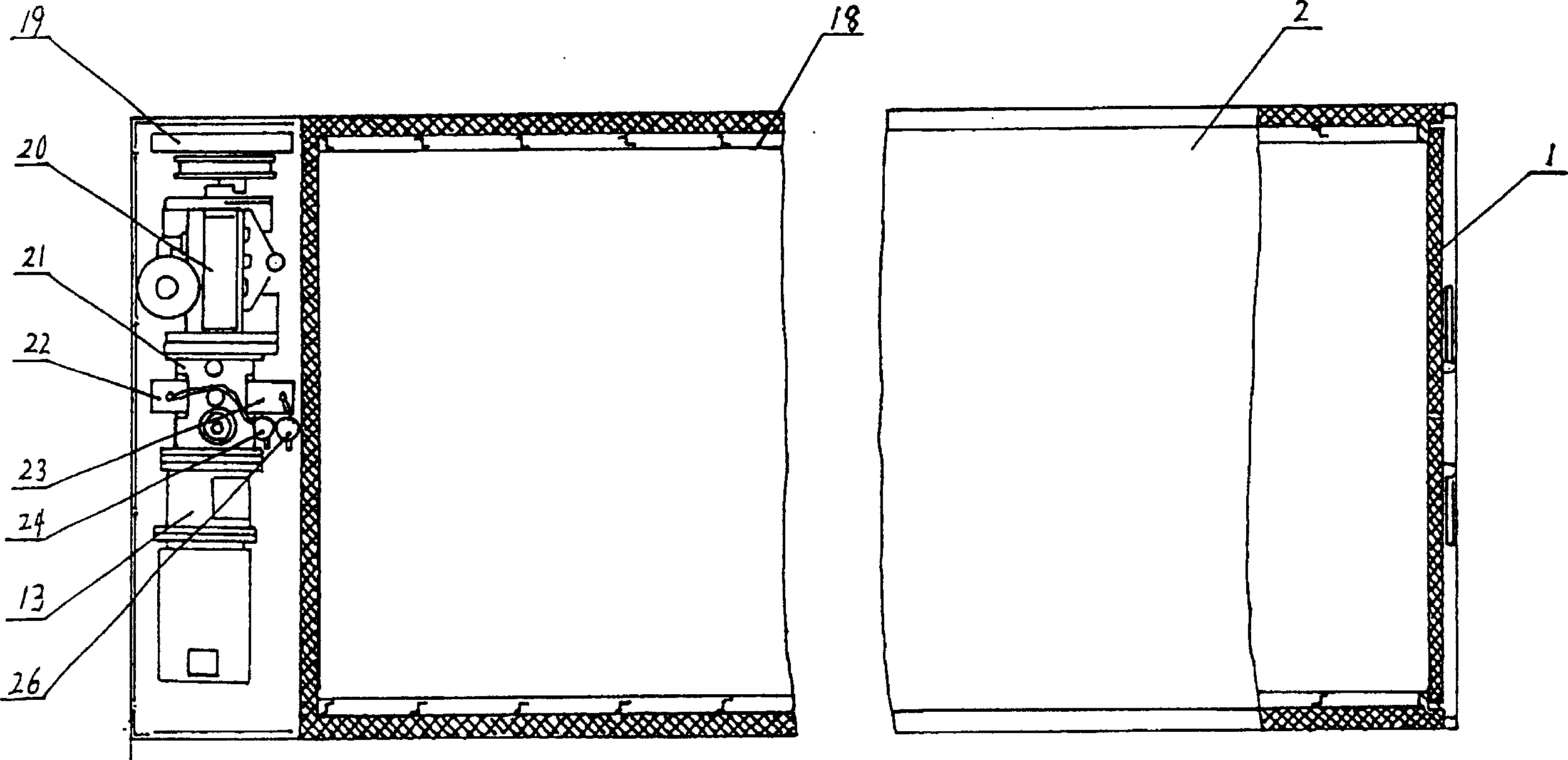

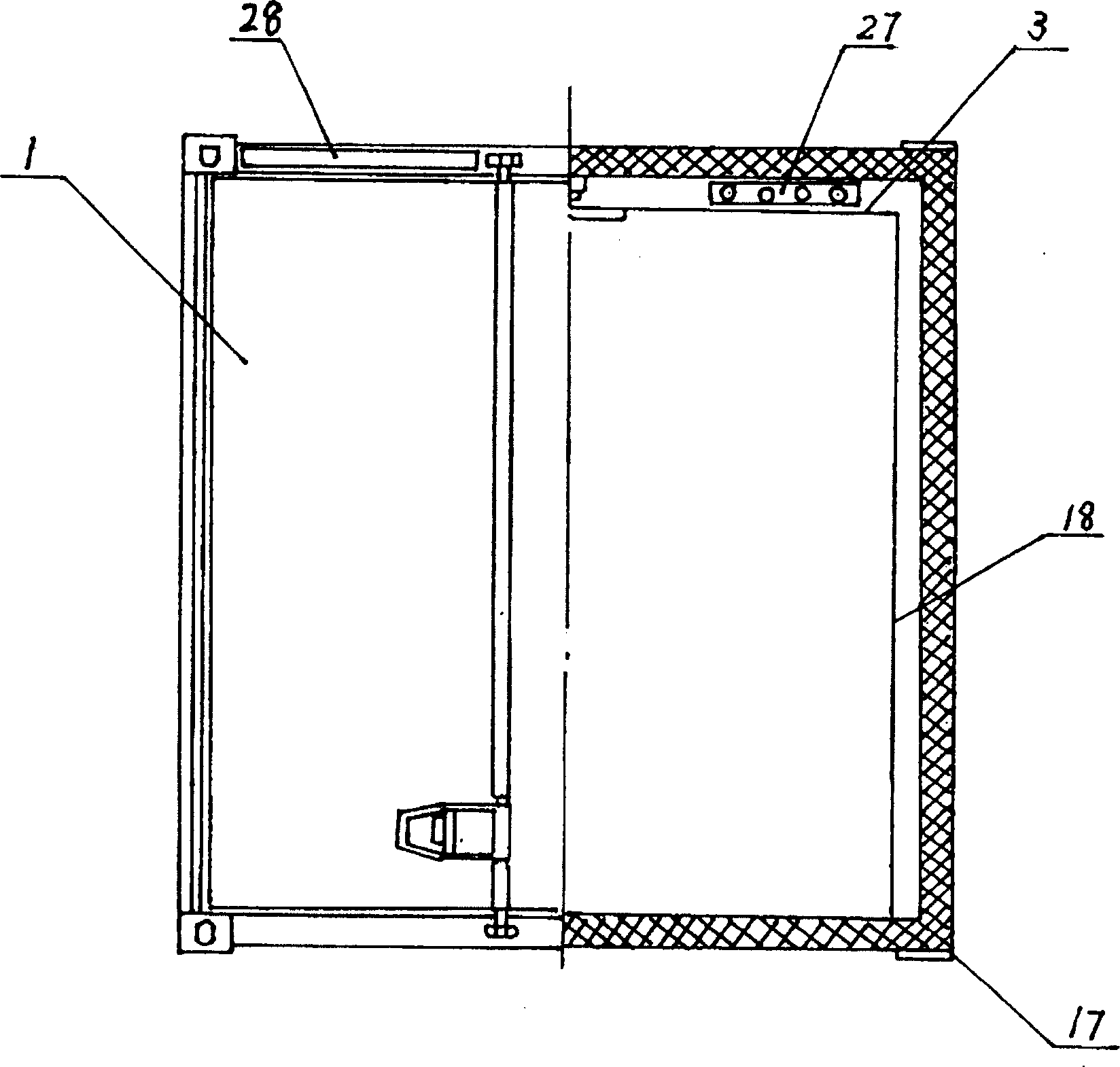

Cold-storage container with very large volume

A refrigerated box and power box technology, used in the field of containers for material storage or transportation, can solve the problems of prolonged turnaround time, narrowed scope, improper ventilation methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The JLJ100 type precooling refrigerated container is the specific implementation of the above invention. In October 1998, the container was loaded with 15 tons of fattening sheep slaughtered on the spot in Xilinhot, Inner Mongolia. The temperature of the cargo was 38°C. The container was disinfected with ozone and packed in vacuum on the spot. The time before and after loading was 6 hours. After loading the goods, they will go on the road to Guangzhou. 10.5 hours after going on the road, the mutton in the box was pre-cooled and reached the set temperature of -1°C. There is no freezing on the surface of the mutton meat in the box, nor is there any situation above 0°C. It took 7 days to reach Guangzhou during the whole journey. The maximum temperature fluctuation on the way was 0.8°C, and the container itself was not refueled on the way. By the time of wholesale sales, the whole box of goods has not been frozen or deteriorated due to high temperature, and has reached th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com