Evaporator for household refrigerator

A technology for refrigeration devices and evaporators, which is applied in household refrigeration devices, evaporators/condensers, refrigerators, etc., and can solve problems such as costly processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

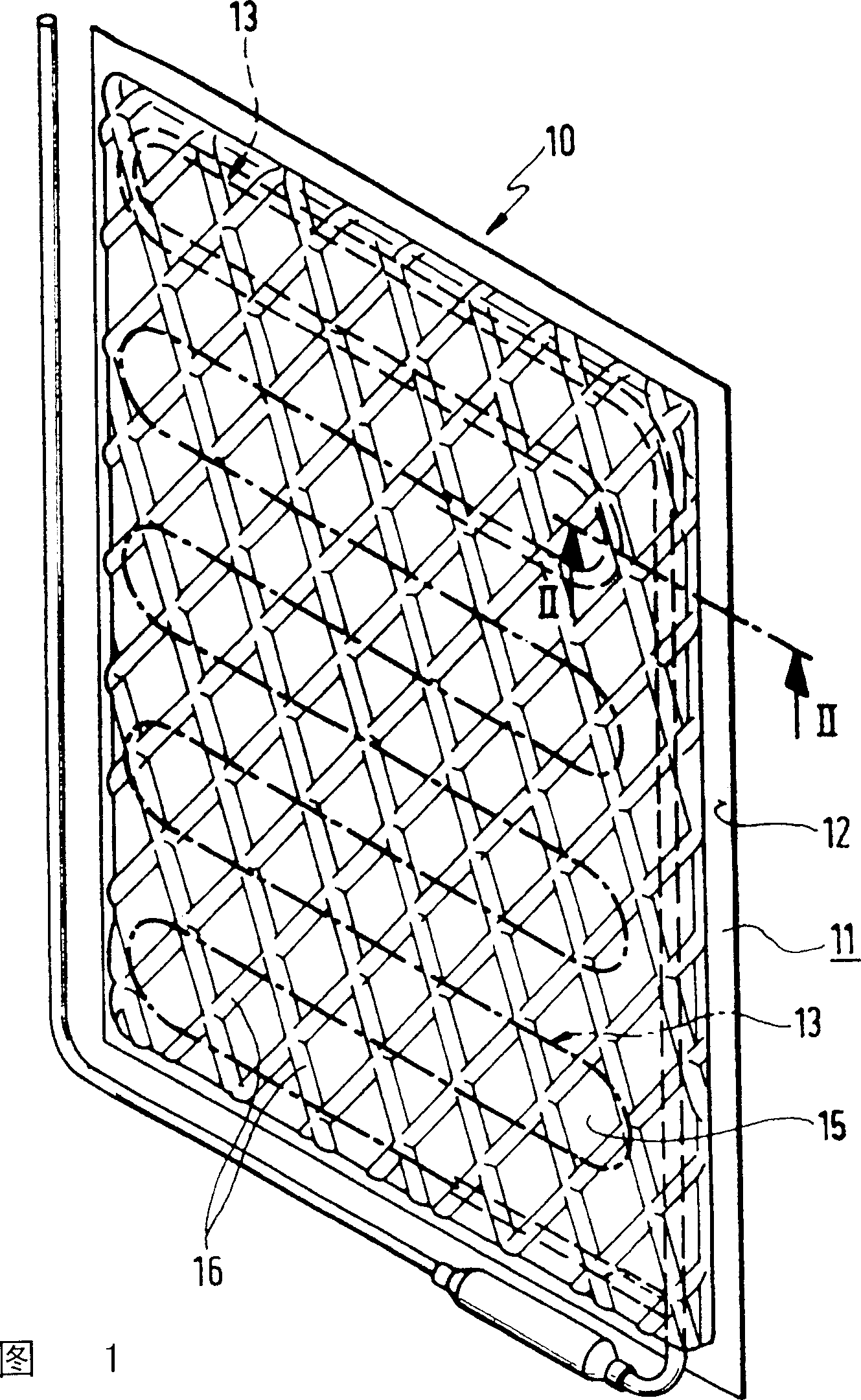

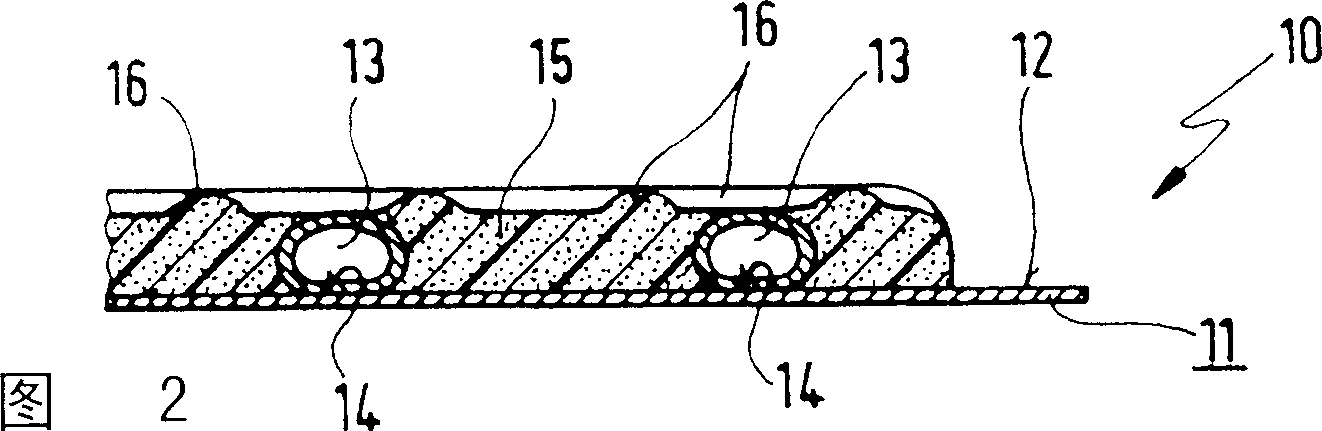

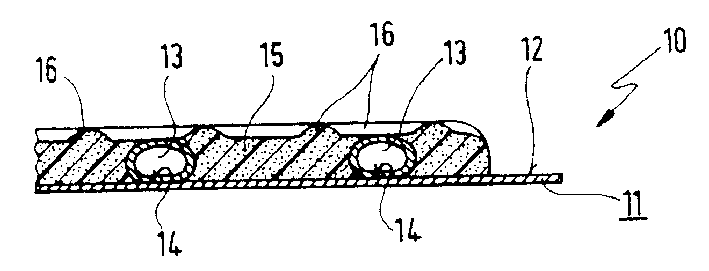

[0023]FIG. 1 shows a plate-shaped evaporator 10, for example used as a so-called cold-wall evaporator, which has a base plate 11 made of a heat-conducting material, such as aluminum or also corrosion-resistant steel sheet or the like. The base plate 11 has a holding surface 12 on one side of its large area, on which a zigzag-shaped pipeline used as a refrigerant medium pipeline 13 is placed in heat conduction contact. The material is a thermally conductive material such as aluminum or corrosion-resistant steel or similar. In order to form the best heat conduction from the refrigerant medium pipeline 13 to the base plate 11, the cross section of the refrigerant medium pipeline 13 with a circular cross section is changed in shape, so that the refrigerant medium pipeline basically It has a D-shaped cross-section, and its supporting surface 14 is basically flat. The supporting surface 14 of the refrigerant medium pipeline 13 is in thermal contact with the base plate 11 (see FIG. 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com