Process for producing flat heat excahnger tubes

A technology of heat exchange tubes and manufacturing methods, applied in the direction of heat exchange equipment, manufacturing tools, metal rolling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

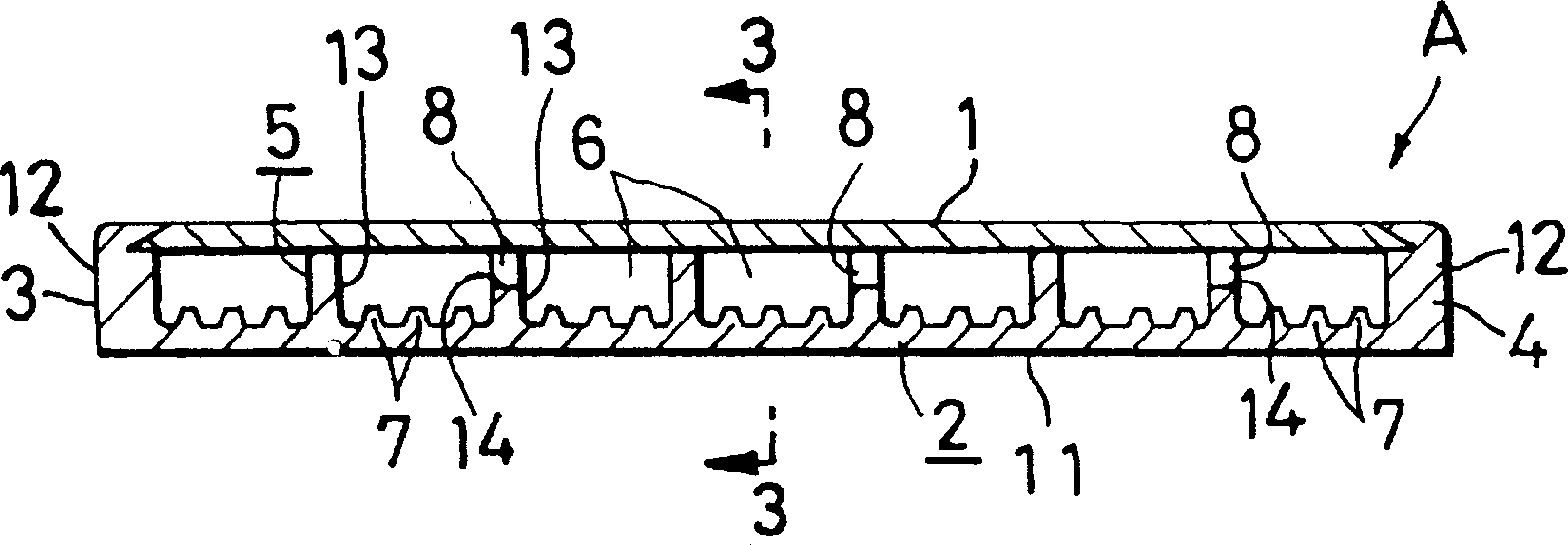

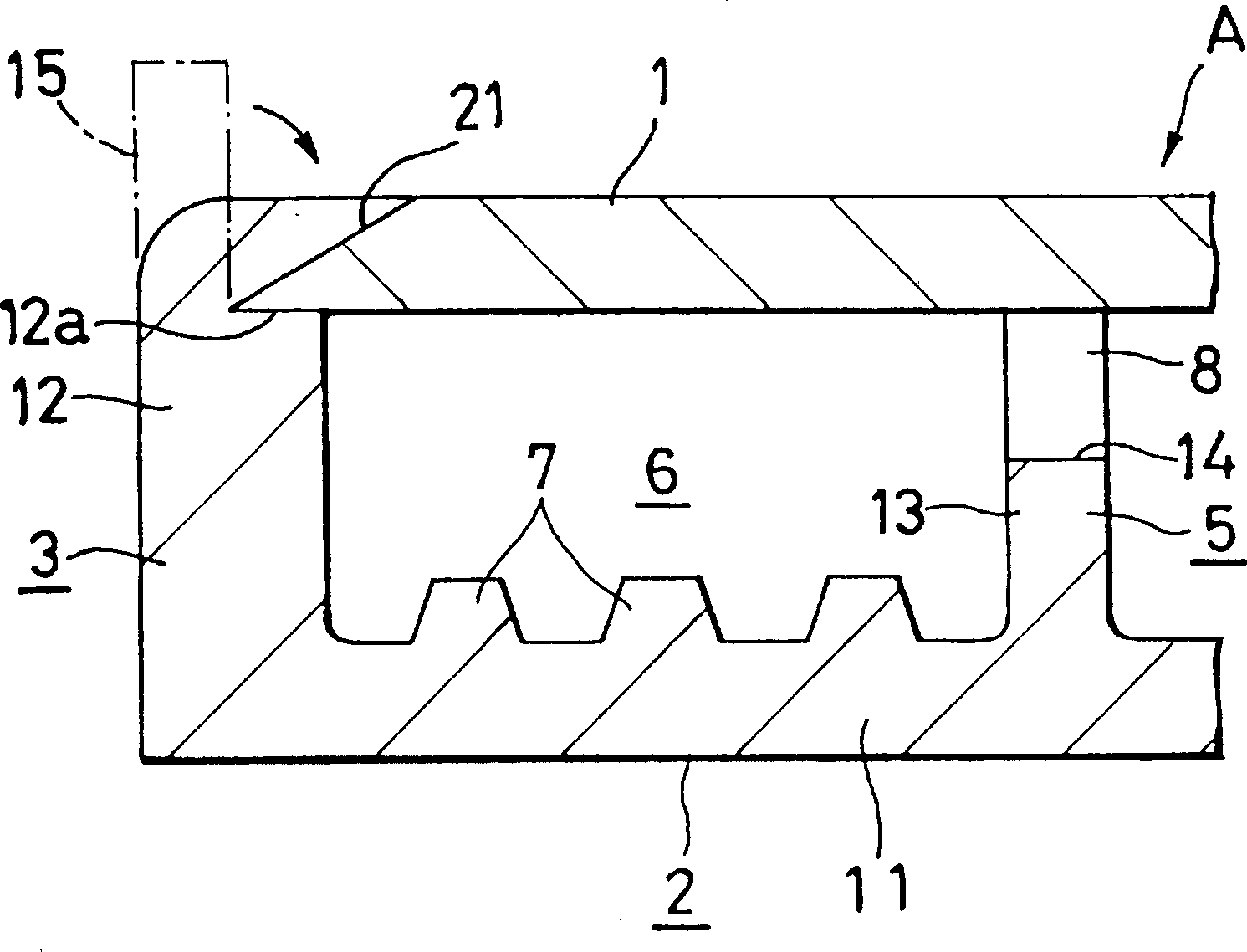

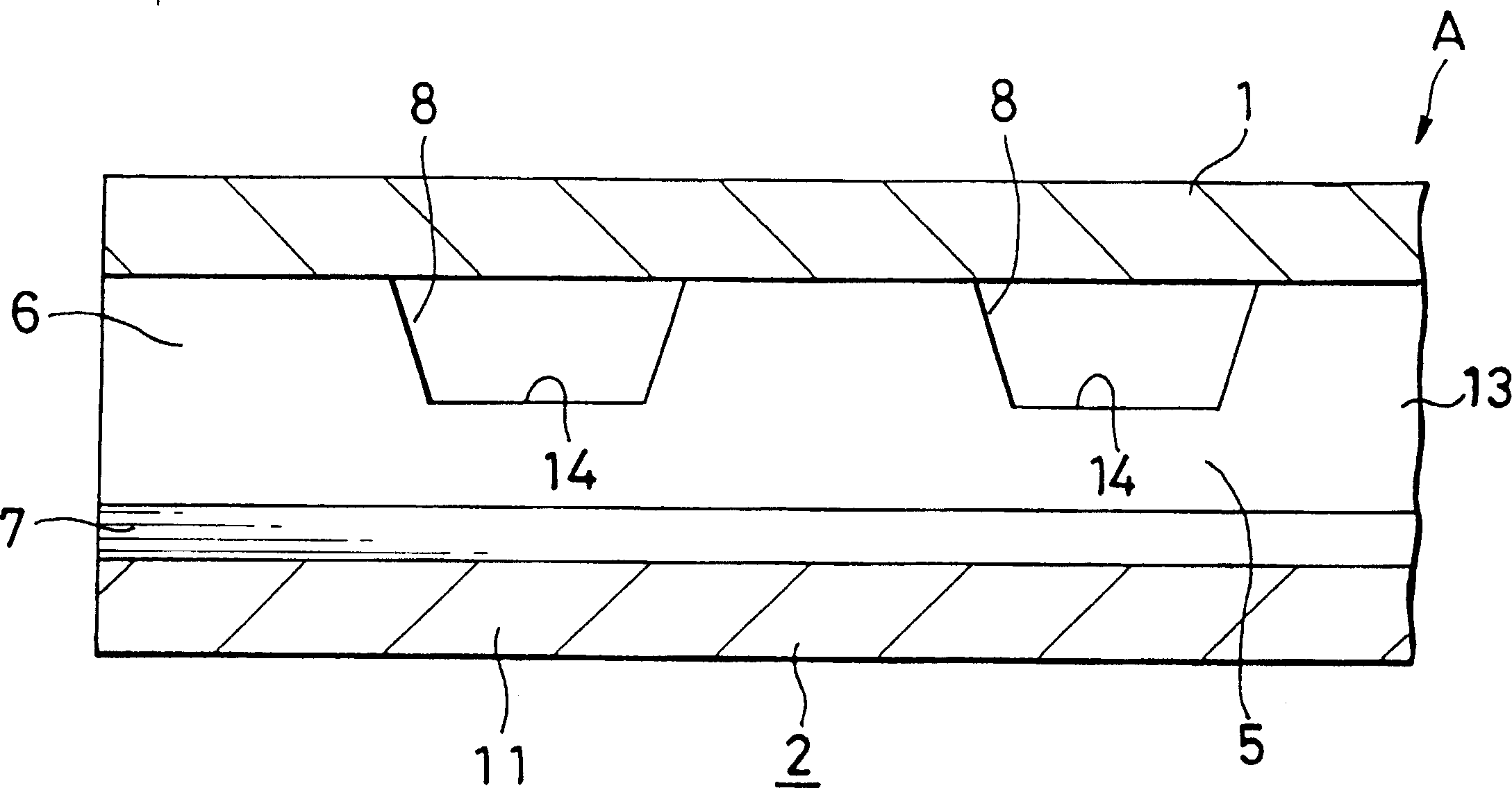

[0043] Figure 1 ~ Figure 1 1 indicates Example 1. Such as Figure 1 ~ Figure 3 As shown, the flat heat exchange tube (A) manufactured by the method of embodiment 1 is provided with: flat upper and lower walls (1), (2) brazed with cooling fins; straddling the upper and lower walls (1), ( 2) on the left and right side edges, the vertical left and right side walls (3), (4); between the left and right side walls (3), (4), across the upper and lower walls (1), (2) and A plurality of reinforced walls (5) extending along the length direction and arranged at a certain interval with each other; there are parallel refrigerant passages (6) inside. Low protrusions (7) for increasing the heat transfer area are integrally formed between mutually adjacent reinforcing walls (5) on the upper surface of the lower wall (2). A plurality of trapezoidal communication holes (8) are opened at the upper end of each reinforcing wall (5) to communicate the parallel refrigerant passages (6) with each...

Embodiment 2

[0060] 12 to 15 are diagrams showing Example 2. FIG.

[0061] The flat heat exchange tube (A) manufactured by the method of embodiment 2 1 ) as shown in Figure 12 and Figure 13, except that the left and right side walls (50), (51) form a double structure, the rest are all and

[0062] Embodiment 1 is the same.

[0063] Flat heat exchange tube (A 1 ) is composed of a lower structural member (60) and an upper structural member (70), but in the lower structural member (60), the left and right standing parts (61) have the same height and thickness as the protruding strip (5), and the flat part ( 11) The outward and upward slopes (62) are formed below the two side edges; and, in the upper structure (70), a hanging part (72) having the same thickness as the upright part (61) is formed on the two side edges. ), the lower ends of the two hanging parts (72) are folded and overlapped on the above-mentioned outwardly upward inclined surface (62), and its cross-section is made to be th...

Embodiment 3

[0070] Figure 16 ~ Figure 18 Figure showing Example 3.

[0071] The flat heat exchange tube (A) manufactured by the method of embodiment 3 2 ),Such as Figure 16 As shown, it is provided with: the flat upper and lower walls (86), (87) of the brazing fins; Side walls (85), (88); between the left and right side walls (85), (88), straddling the upper and lower walls (86), (87) and extending along the length direction and spaced apart from each other at a certain interval A plurality of reinforced walls (89); there are parallel refrigerant passages (74) inside. A plurality of hexagonal communication holes (90) for communicating the parallel refrigerant passages (74) are opened at the center of the height of each reinforcing wall (89).

[0072] Flat heat exchange tube (A 2 ) consists of 1 structural member (94). Such as Figure 17 As shown, the structural member (94) is provided with a central flat portion (92) forming the right side wall (88) in the center of the width, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com