Method for producing nitric acid

A technology of nitric acid and absorption zone, applied in the direction of nitric acid, chemical instruments and methods, nitrogen oxides/oxo acids, etc., can solve the problems of not being disclosed, and achieve the effect of improving color quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

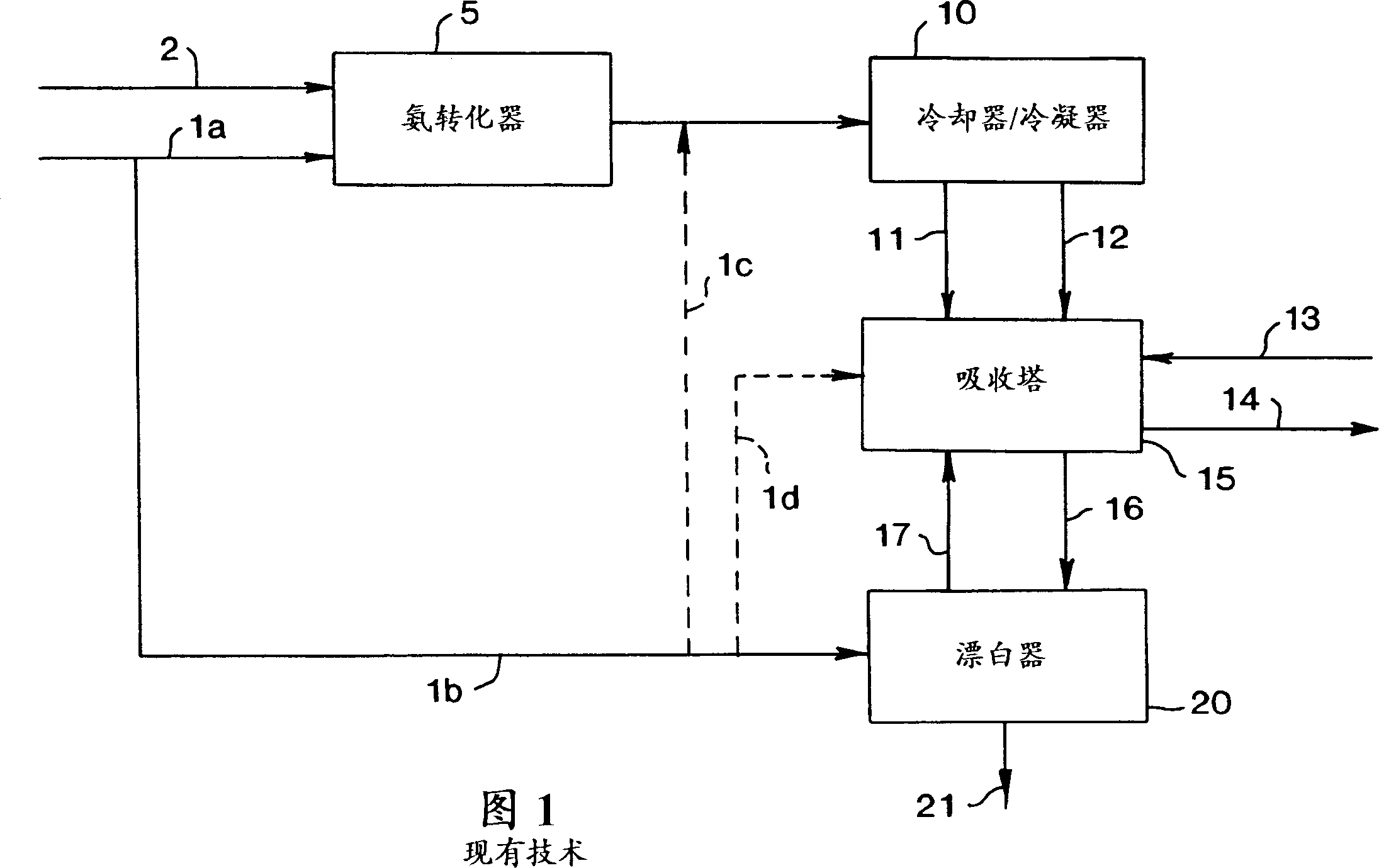

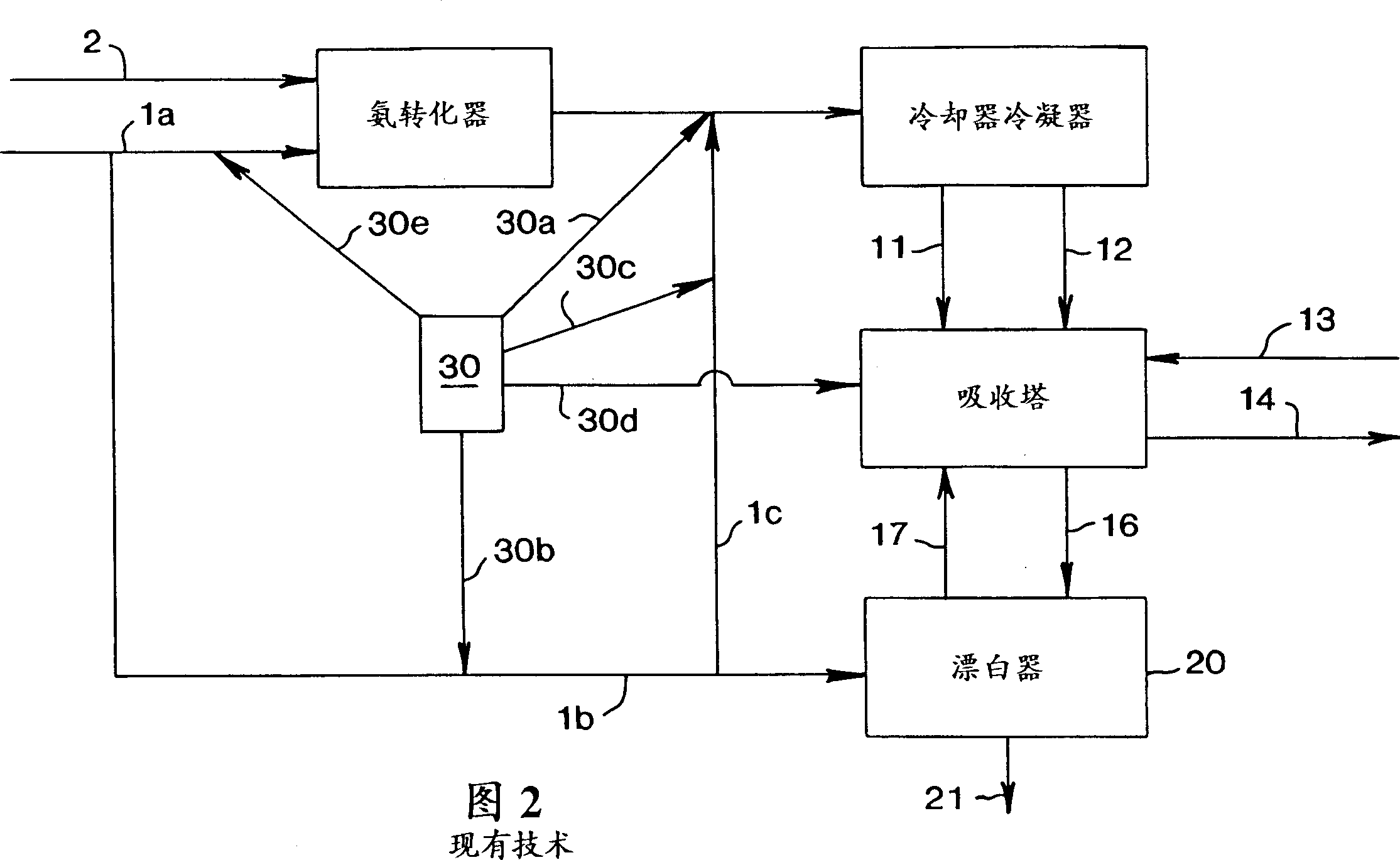

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] All patent applications, patents and literature cited in this specification are incorporated by reference in their entirety.

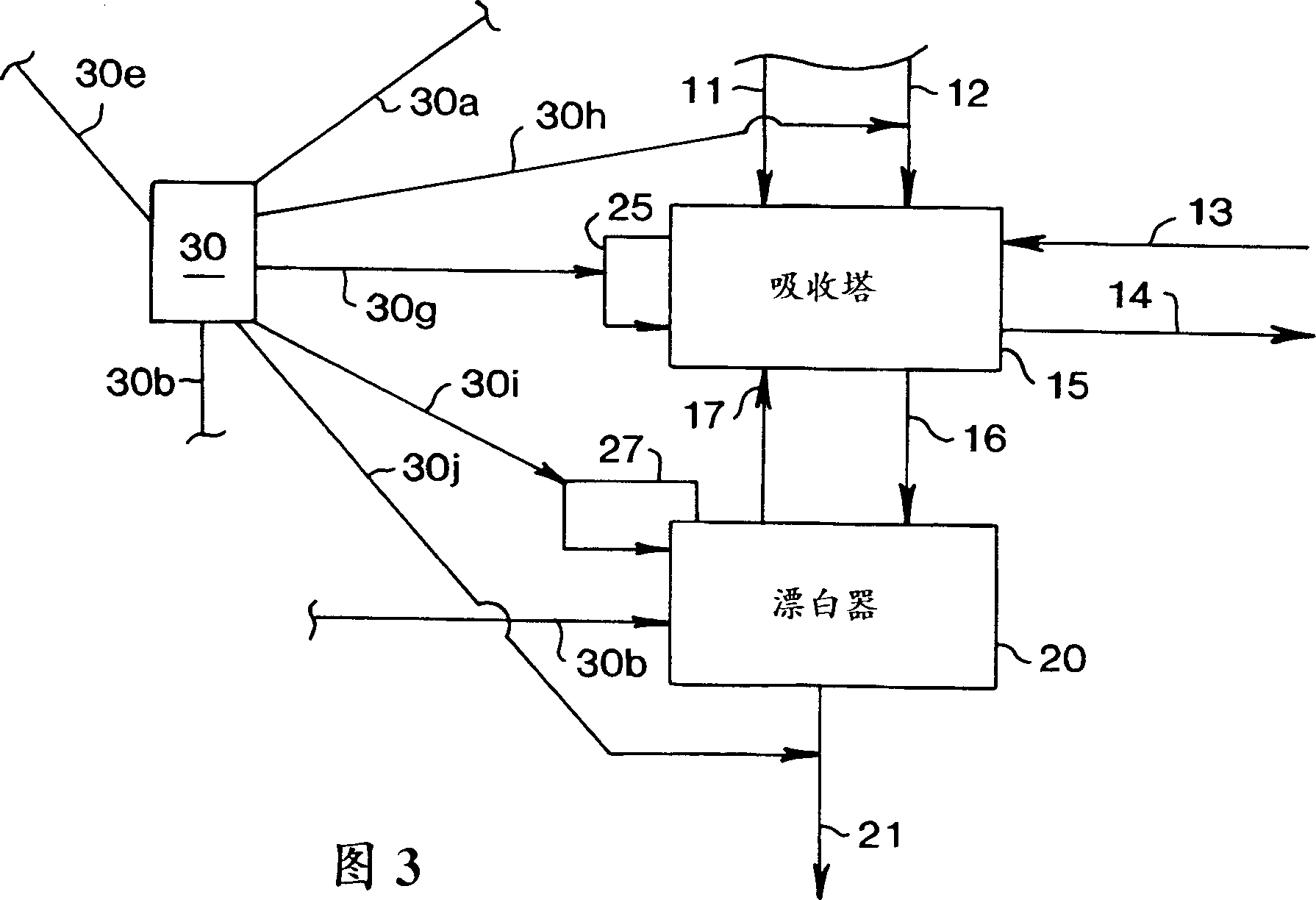

[0074] The method of the present invention is accomplished using an in-line gas dispersion device capable of forming gas bubbles with a diameter below about 0.1 mm. A preferred device is an in-line sonic stripper, such as that available from Praxair and described in US Patent 5,302,325. The online gas dispersing device of US Patent No. 5,302,325 can accelerate part of the gas / liquid mixture to supersonic velocity and then decelerate the mixture to subsonic velocity. Acoustic shock waves are formed in the mixture in such a way that very fine bubbles are created which raise the interface surface between gas and liquid.

[0075] Oxygen can be introduced into the aqueous nitric acid wherever there is such a stream in the production process by the method of the present invention, particularly anywhere between the cooler / condenser chain 10 and the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com