Filter plate of filter press

A filter press and filter plate technology, which is applied to the filter plate field of a filter press, can solve problems such as large workload, and achieve the effects of less maintenance, low manufacturing cost and less wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

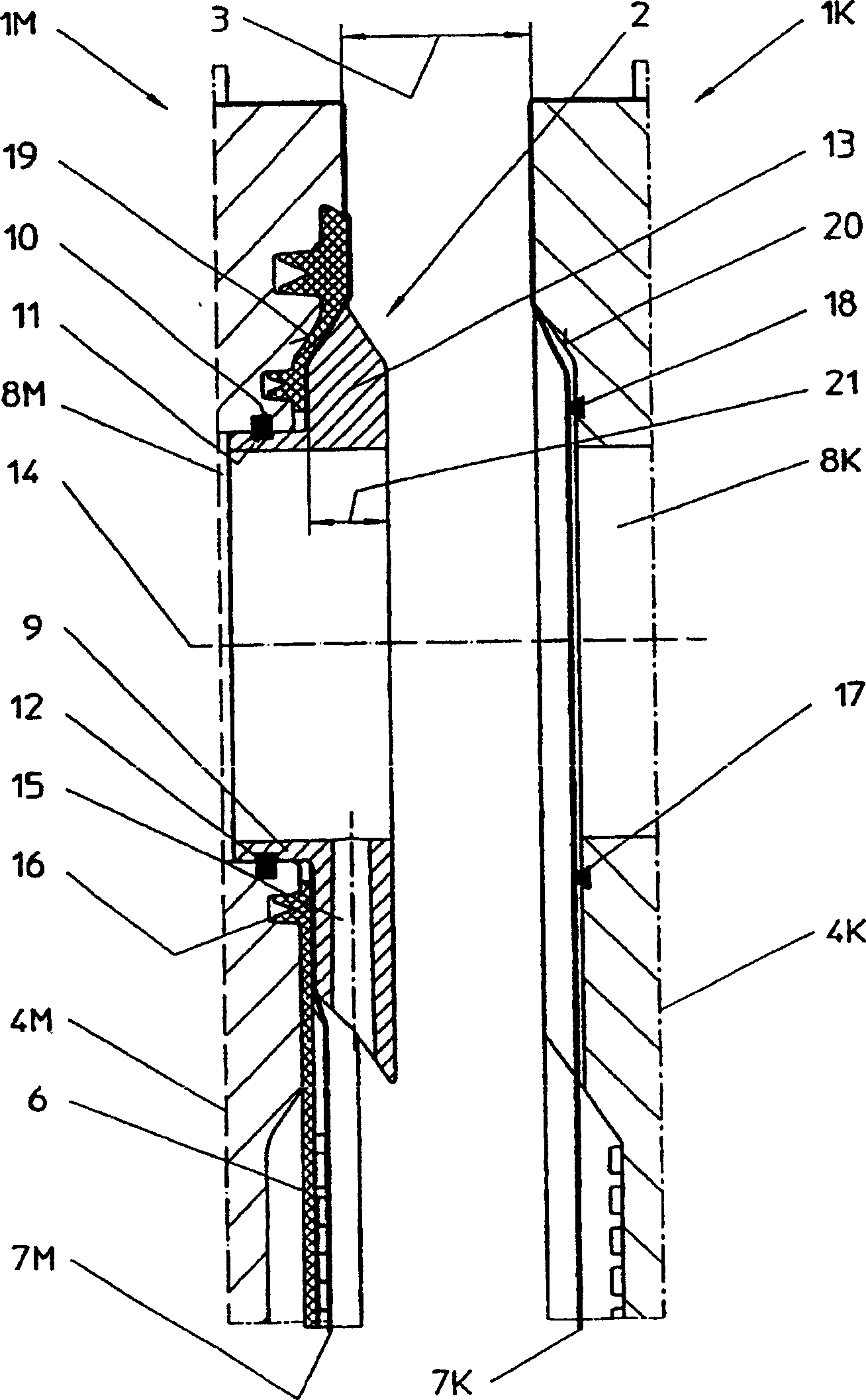

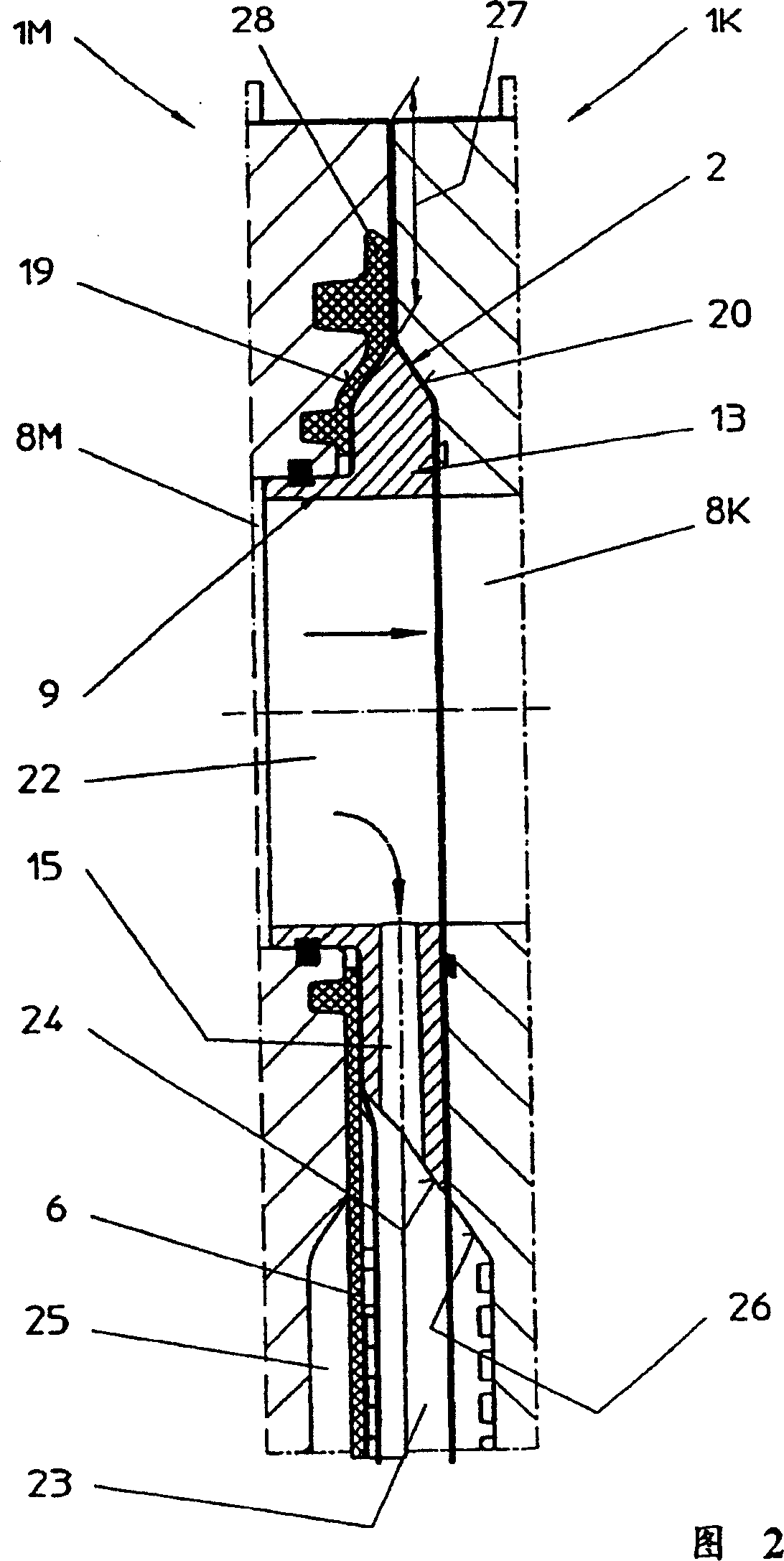

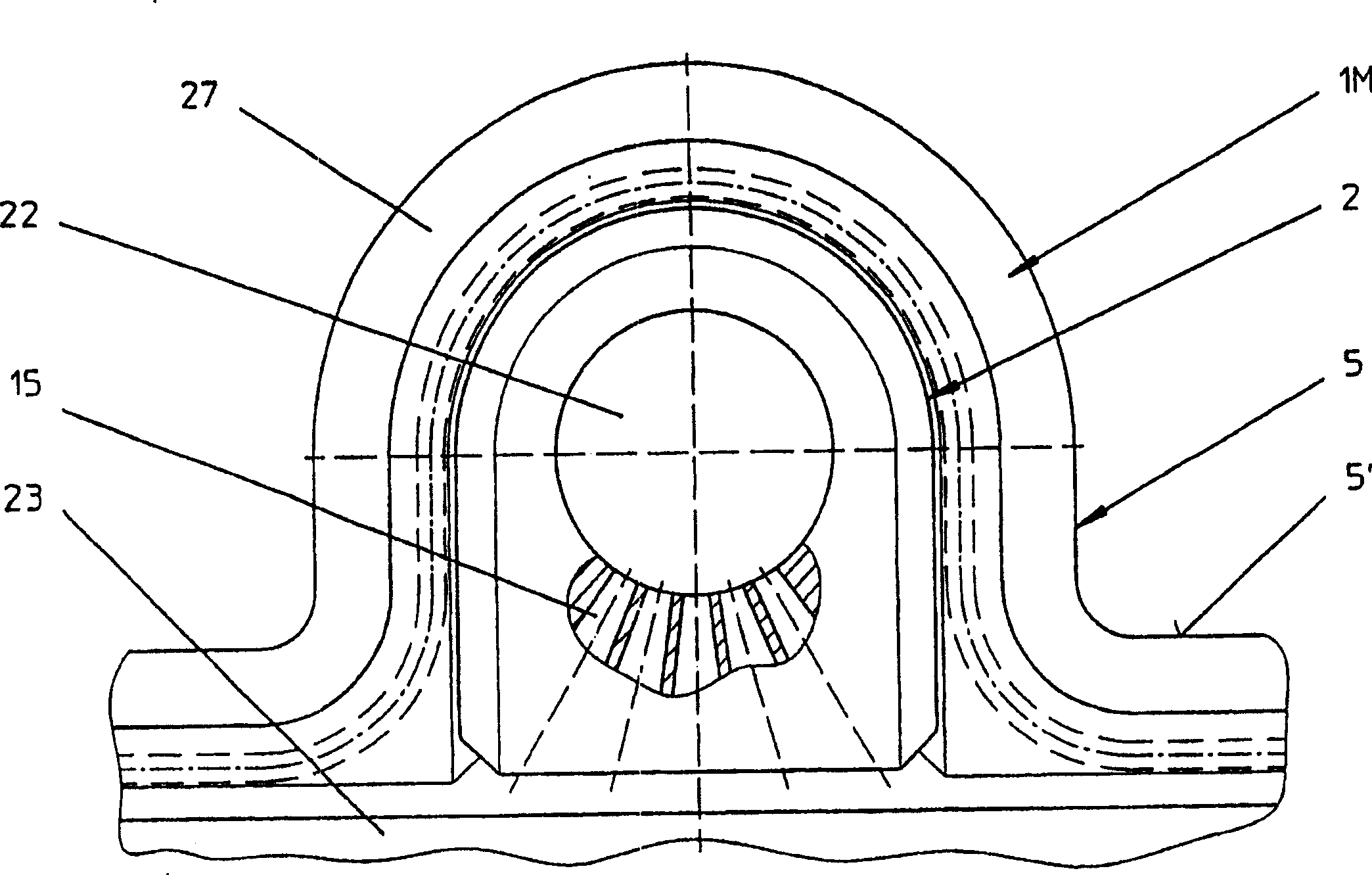

[0033] figure 1 The left half of the figure shows a longitudinal section through the right half of a filter plate used as a membrane plate 1M, but only its region in which the feed element 2 is inserted is shown. figure 1 The right half of FIG. 1 shows a chamber plate 1K separated from the membrane plate 1M by a slag discharge distance, but only its left half is shown. Both the membrane plate 1M and the chamber plate 1K are designed symmetrically with respect to their planes of symmetry 4M and 4K. For the sake of brevity, the halves of the sections of the two plates described which are opposite to each other and have the same structure are omitted in the figure. also, figure 1 The longitudinal sectional view of only shows the uppermost part of the filter plates 1M and 1K aligned in the vertical direction, that is, at the filter plate edge 5' (which becomes the upward boundary of the substantially rectangular filter plate filter area in the filter plate 1M ) above the Annex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com