Composite roller for two cooling regions of conticaster

A compound roll and continuous casting technology, which is applied in the field of back-up rolls for continuous casting machines, can solve the problems of uneven cooling on the surface of the slab, temperature rise of the slab shell, and easy occurrence of intermediate cracks in the slab, so as to accelerate heat transfer efficiency and cooling Uniform temperature and good billet quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

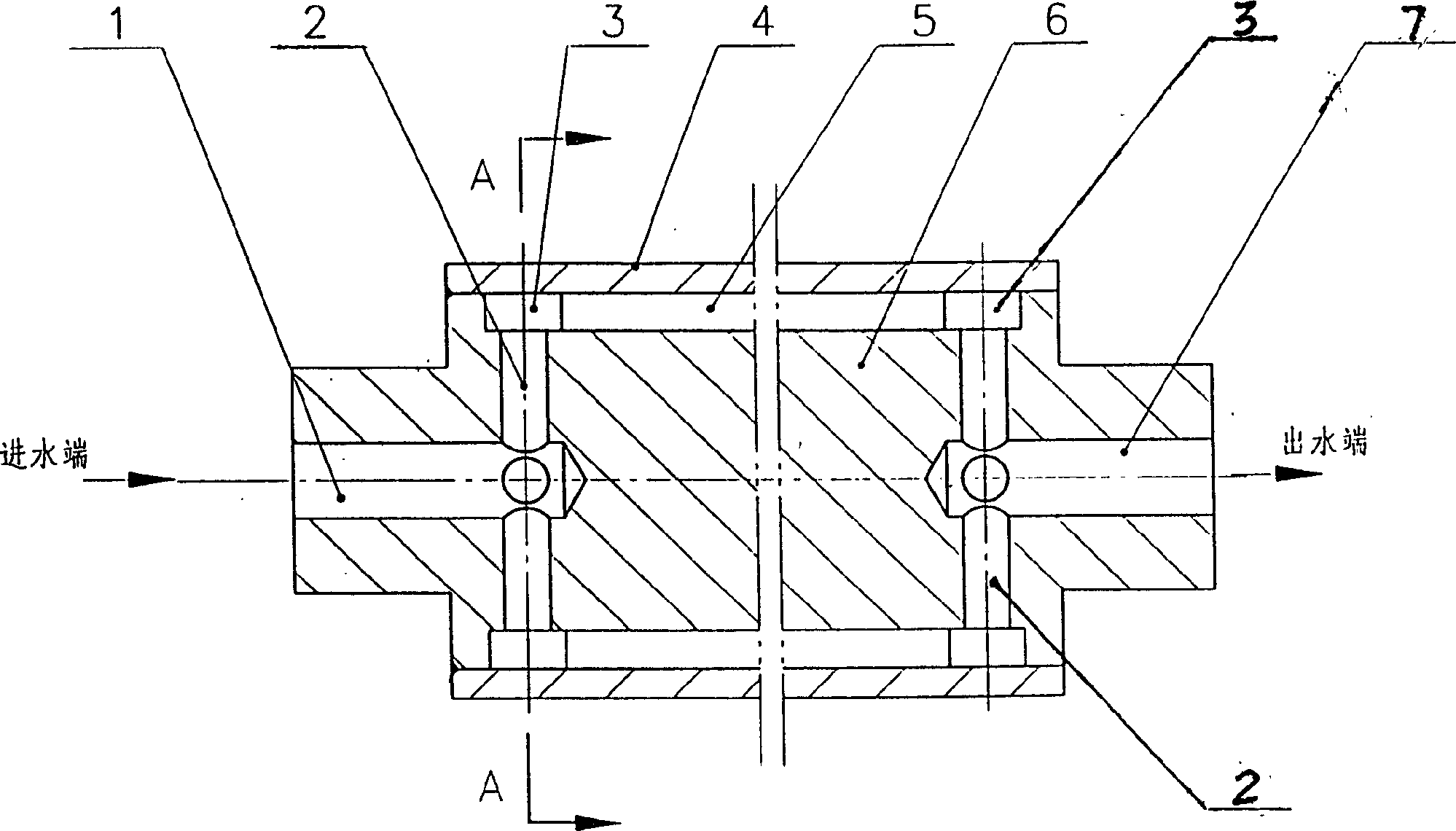

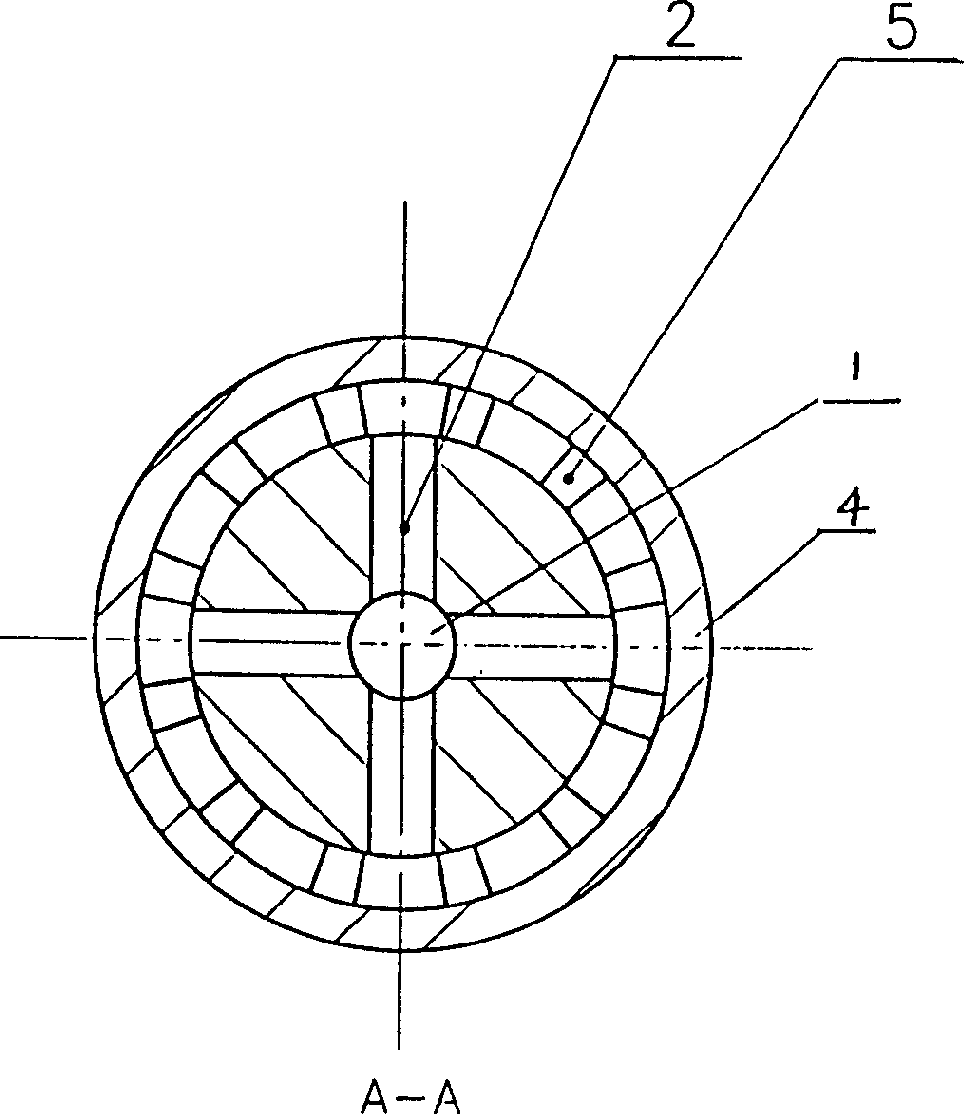

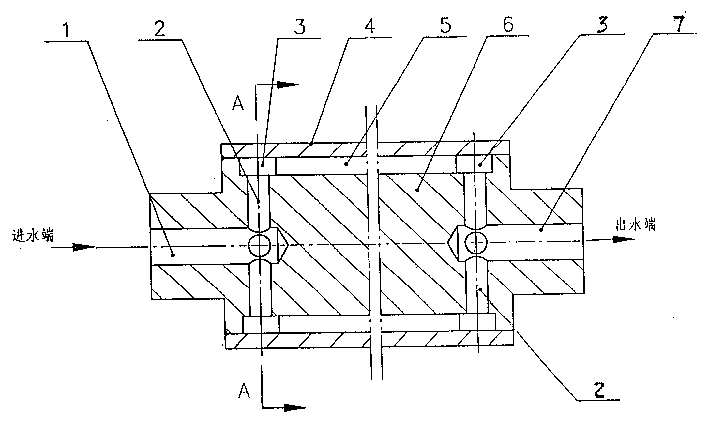

[0009] see attached figure 1 , 2 , the present invention includes a roller body and a casing, a water inlet pipe and a water outlet pipe, the roller body 6 is made of high temperature resistant, high-strength alloy steel, and is characterized in that the outer surface of the roller body 6 has a circumferential cooling water groove equally divided in the circumferential direction 5. The roller body 6 is radially provided with a water distribution hole 2, one end of the annular water distribution pipe 3 is connected with the radial water pipe 2, and the other end is connected with the circumferential cooling water groove 5 respectively. The water inlet pipe 1 and the water outlet pipe 7 which are connected with the water hole 2 are installed with a sleeve 4 on the roller body 6 with the circumferential cooling water groove 5. The copper sleeve 4 of the outer layer is formed into one body with the inner layer roller body 6 by shrinking or other methods after being rolled. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com