Technology for producing semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device production, can solve problems such as chip breakage, effort, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

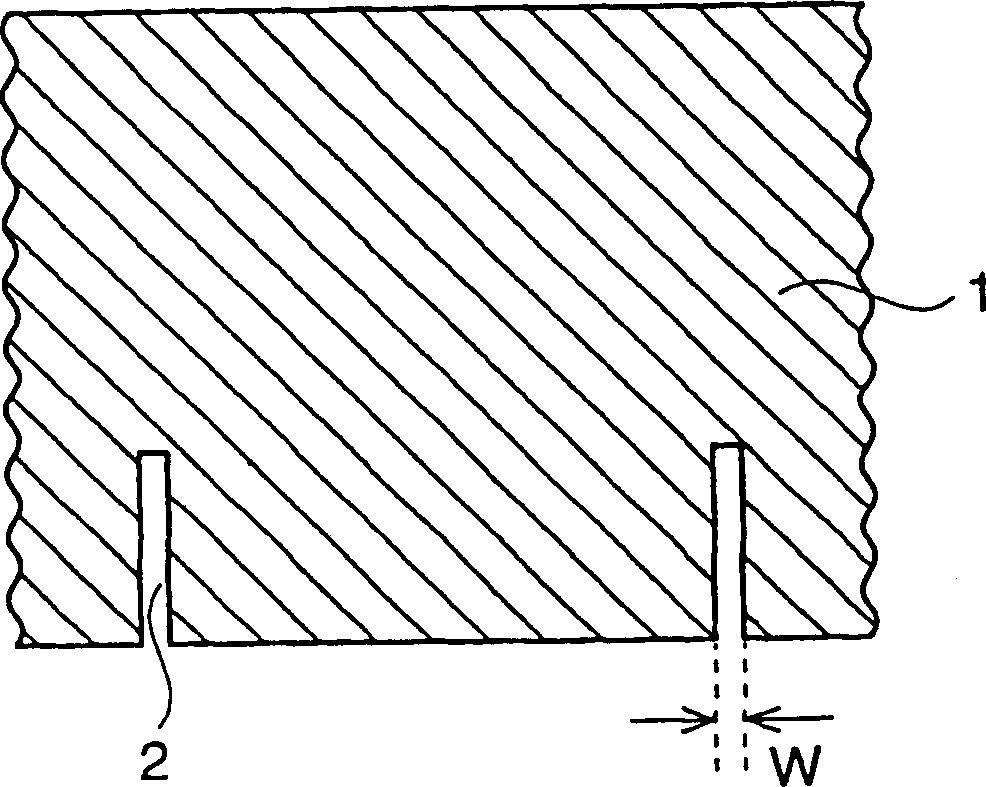

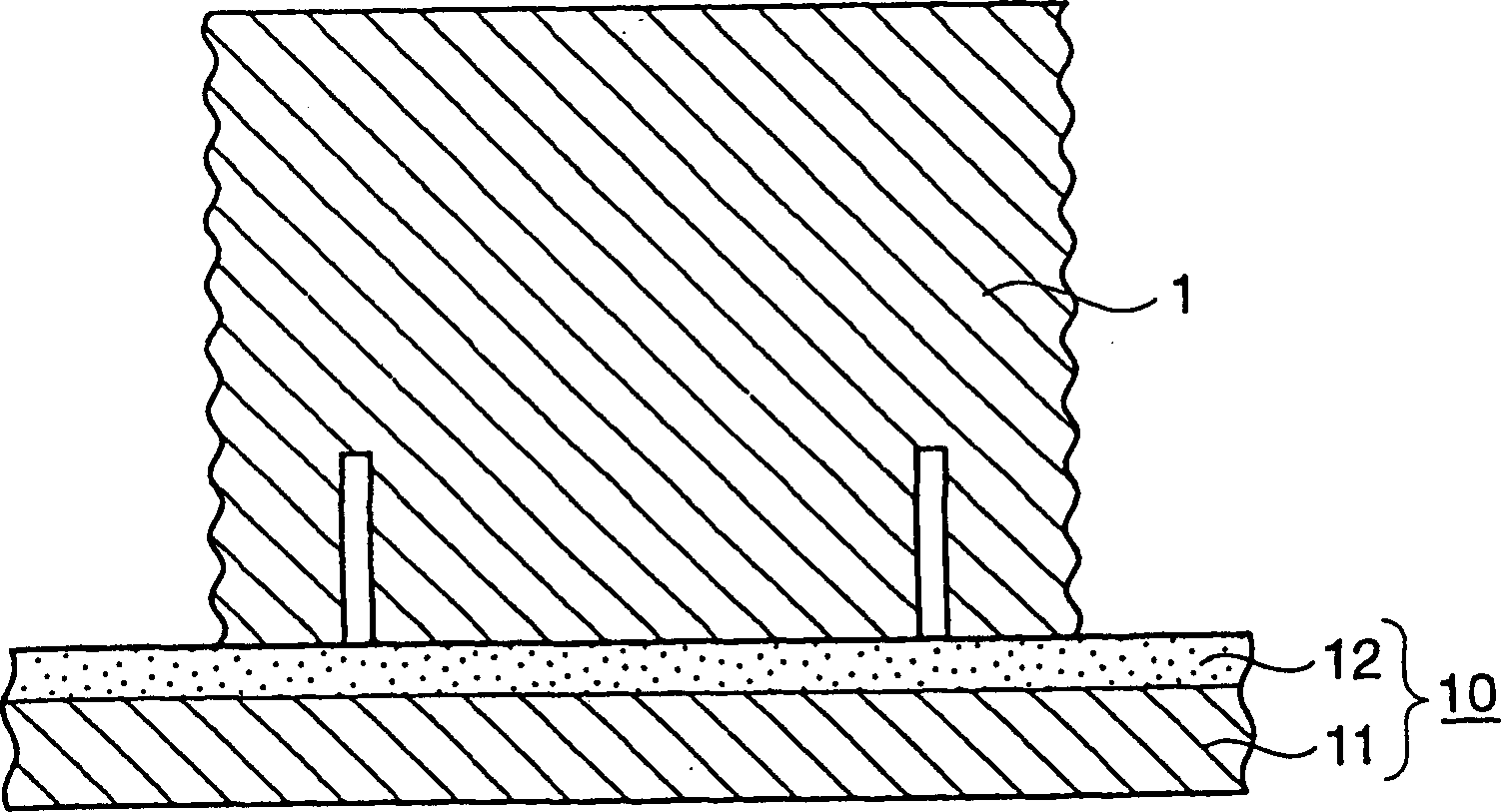

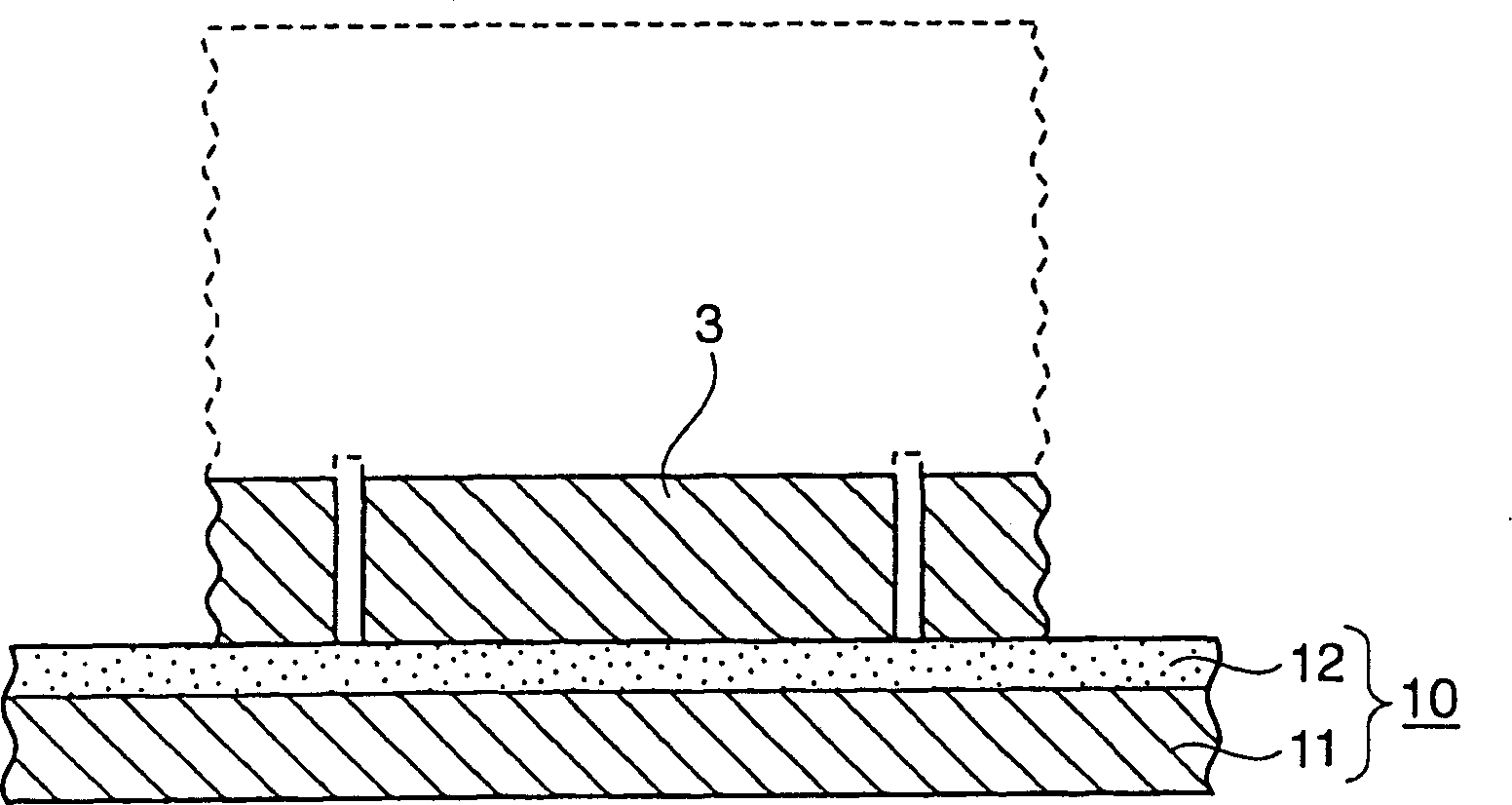

[0072] A silicon wafer with a diameter of 6 inches and a thickness of 700 μm was glued to a dicing tape (Adwill D-628), using a wafer slicer (DAD 2H / 6T, manufactured by Disco Corporation) with a blade width of 35 μm, at a cutting depth of 400 μm and Grooves were formed under the condition that the chip size was 6 mm2. Subsequently, a thin layer of surface protection is adhered to the grooved surface of the wafer. The dicing tape was peeled off, and the back surface of the wafer was ground using a back grinder (DFG 840, manufactured by Disco Corporation) until its thickness became 80 μm, thereby achieving separation of the wafer into individual chips. Thereafter, a dicing / die-bonding sheet (Adwill LE5000) was adhered to the ground backside of the wafer (chip), irradiated with ultraviolet light and the surface protective sheet was peeled off. The slice / die-bonding thin layer was irradiated with ultraviolet light, and the adjacent segments located in the divided sections were cu...

example 2

[0075] A silicon wafer with a diameter of 6 inches and a thickness of 700 μm is glued to a dicing tape (Adwill D-628), using a wafer slicer (DAD 2H / 6T, manufactured by Disco Corporation) with a blade width of 35 μm, at a cutting depth of 400 μm and Grooves were formed under the condition that the chip size was 5 mm2. Subsequently, a thin layer of surface protection is adhered to the grooved surface of the wafer. The dicing tape was peeled off, and the back surface of the wafer was ground using a back grinder (DFG 840, manufactured by Disco Corporation) until its thickness became 80 μm, thereby achieving separation of the wafer into individual chips. Thereafter, the dicing / die-bonding thin layer (thermoplastic polyimide film) is heated at about 130°C and adhered to the ground backside of the wafer (chip), and the surface protective thin layer is peeled off. Using a wafer slicer (DAD 2H / 6T, manufactured by Disco Corporation) with a blade width of 30 μm, the adhesive layer betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com