Process for preparing red copper powder from crude copper ore

A technology for red copper powder and copper ore, applied in the field of directly producing red copper powder from copper ore, can solve the problem of high production cost, achieve the effects of low production cost, improve recovery rate and avoid environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

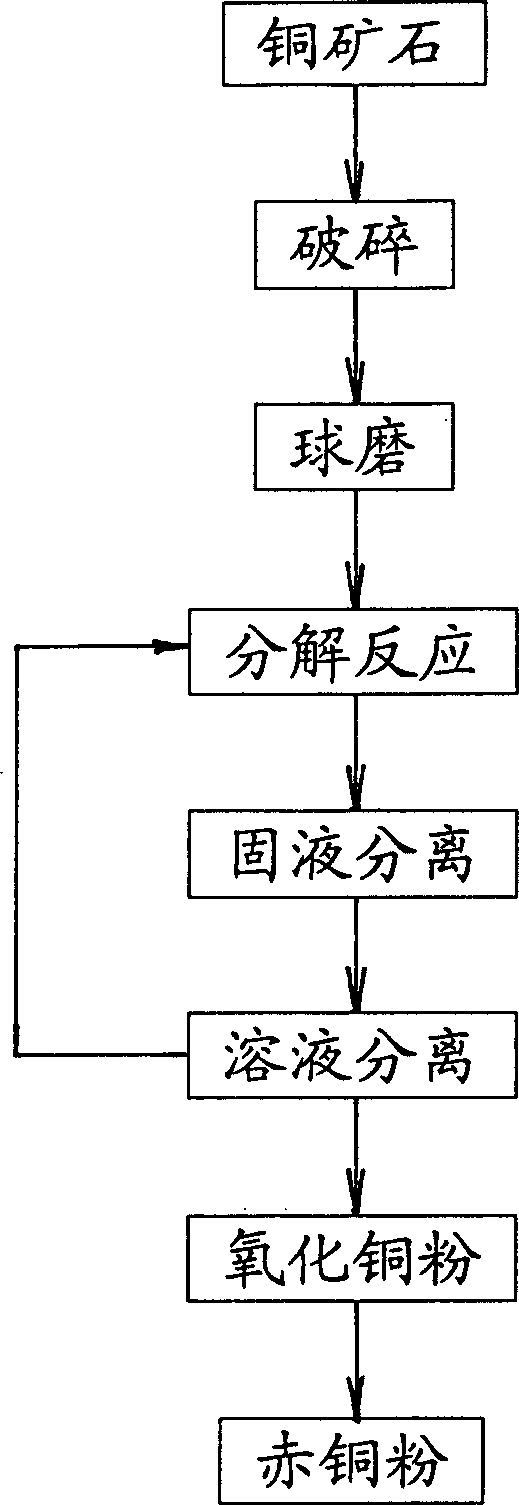

[0012] like figure 1 As shown, copper ore is directly used as raw material, and red copper powder is produced through the following process:

[0013] (1) crushing: the copper oxide bonded ore is crushed, and the particle size is 3 cm;

[0014] (2) Ball milling: Wet mill the crushed ore to form ore pulp with a graded particle size of 200 mesh, which is conducive to full decomposition during the decomposition process;

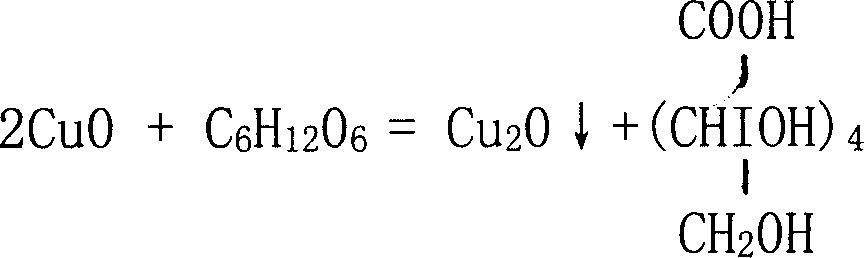

[0015] (3) Decomposition reaction: inject the ore slurry into the paddle-type reactor, and add liquid ammonia and water to make the pH value of the solution reach 13, then add sodium carbonate and sodium hydroxide as catalysts, water and sodium carbonate, sodium hydroxide The weight ratio of the reactor is 100:2:2, heating and pressurizing makes the temperature in the reactor reach 80° C., the pressure reaches 5 MPa, and the reactor runs for 3 hours. The main chemical reaction equation in the decomposition process is as follows:

[0016] Decomposition of basic...

Embodiment 2

[0029] Directly use copper ore as raw material, and produce red copper powder through the following process: (1) crushing: crushing the copper oxide bonded ore; (2) ball milling: wet grinding the crushed ore to form a slurry; (3) Decomposition reaction: inject the ore slurry into the paddle-type reactor, and add liquid ammonia and water to make the pH value of the solution reach 12, then add sodium carbonate and sodium hydroxide as catalysts, the weight ratio of water to sodium carbonate and sodium hydroxide 100:1:1, heated and pressurized so that the temperature in the reactor reached 70°C, the pressure reached 3Mpa, and the reactor was run for 2 hours; (4) solid-liquid separation: use a filter press to separate the copper ammine ion solution from the tail Mine separation; (5) Solution separation: heat and pressurize the copper ammonium ion solution to separate copper oxide powder at a temperature of 150°C and a pressure of 6Mpa, and return the ammonia, carbonic acid and sodiu...

Embodiment 3

[0031] Directly use copper ore as raw material, and produce red copper powder through the following process: (1) crushing: crushing the copper oxide bonded ore; (2) ball milling: wet grinding the crushed ore to form a slurry; (3) Decomposition reaction: inject the ore slurry into the paddle-type reactor, and add liquid ammonia and water to make the pH value of the solution reach 12, then add sodium carbonate and sodium hydroxide as catalysts, the weight ratio of water to sodium carbonate and sodium hydroxide 100: 3: 3, heated and pressurized so that the temperature in the reactor reached 70°C, the pressure reached 6Mpa, and the reactor was operated for 3 hours; (4) solid-liquid separation: use a filter press to separate the copper ammonium complex ion solution from the tail Mine separation; (5) solution separation: heat and pressurize the copper ammonium ion solution, the temperature is 170°C, the pressure is 8Mpa, and the copper oxide powder is separated, and the ammonia, carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com