Multifunctional oil increasing controlling method and controller

A multi-functional, controller technology that is used in earth-moving drilling, production of fluids, wellbore/well components, etc. It can solve the problems of large mechanical wear, narrow speed control range, short life, etc., and achieve strong overload capacity and advanced technology. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described below in conjunction with accompanying drawing.

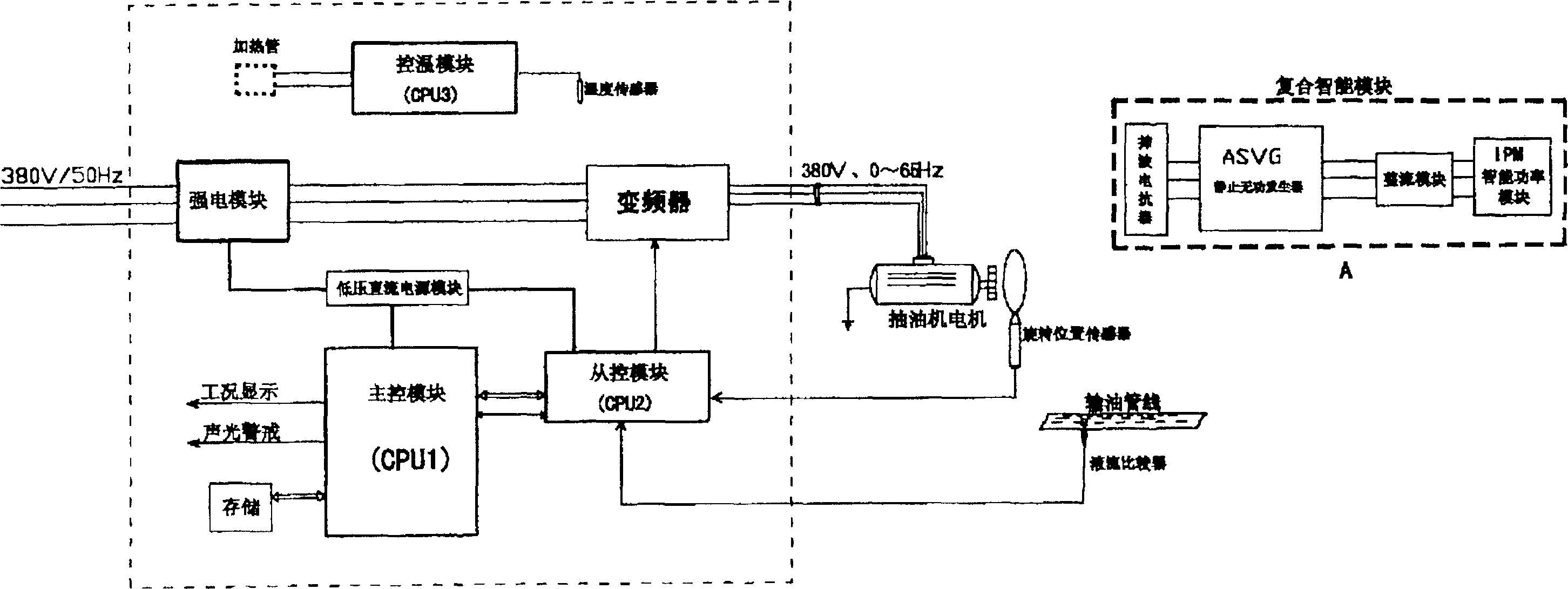

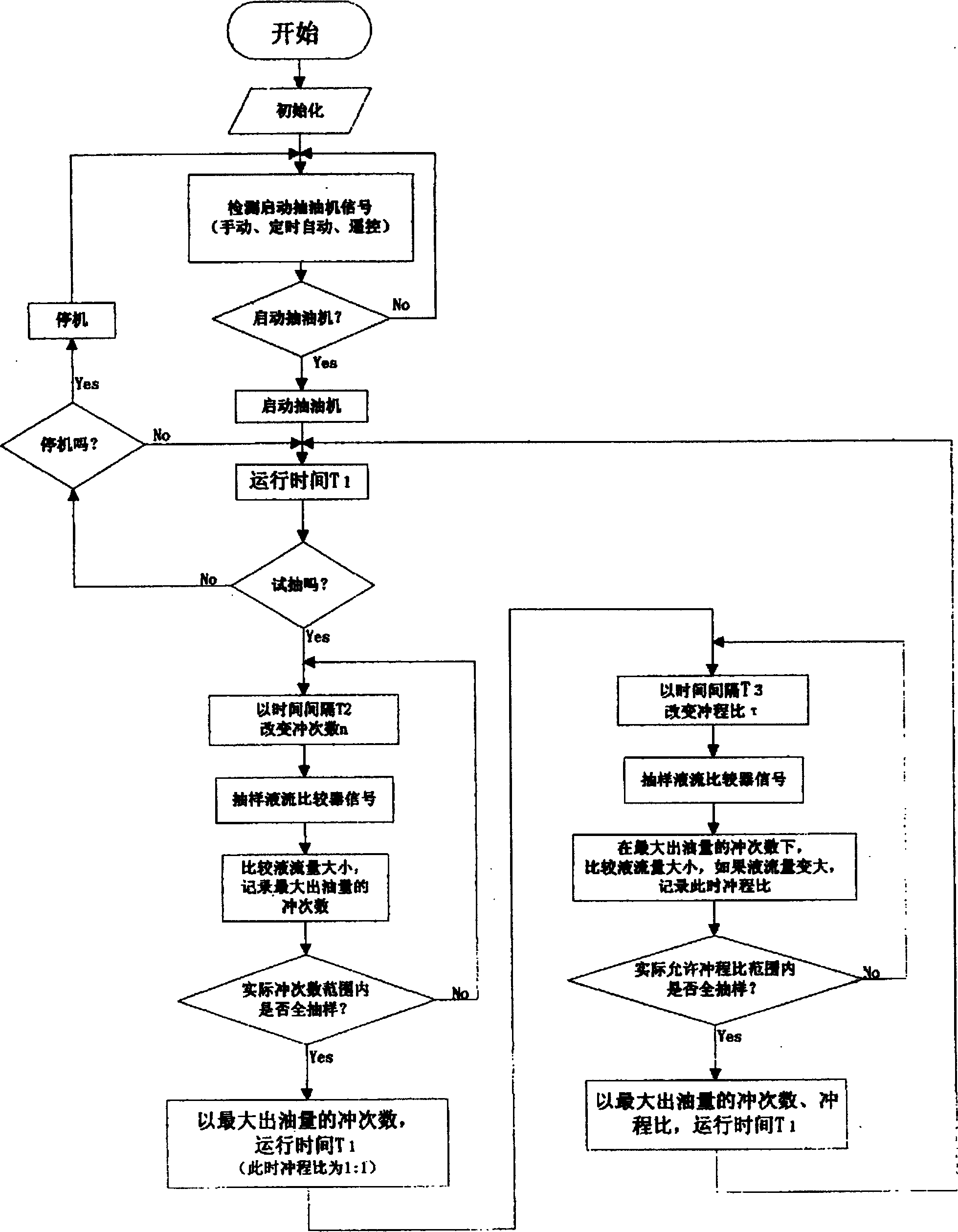

[0018] as attached figure 1 Shown, main part of the present invention has: the oil amount that is placed on the ground has and size comparison sensor (fluid flow comparator), pumping unit moves to each feature point sensor (rotary position sensor), frequency converter (or compound intelligence) module), small environment temperature controller, master control CPU module, slave control CPU module.

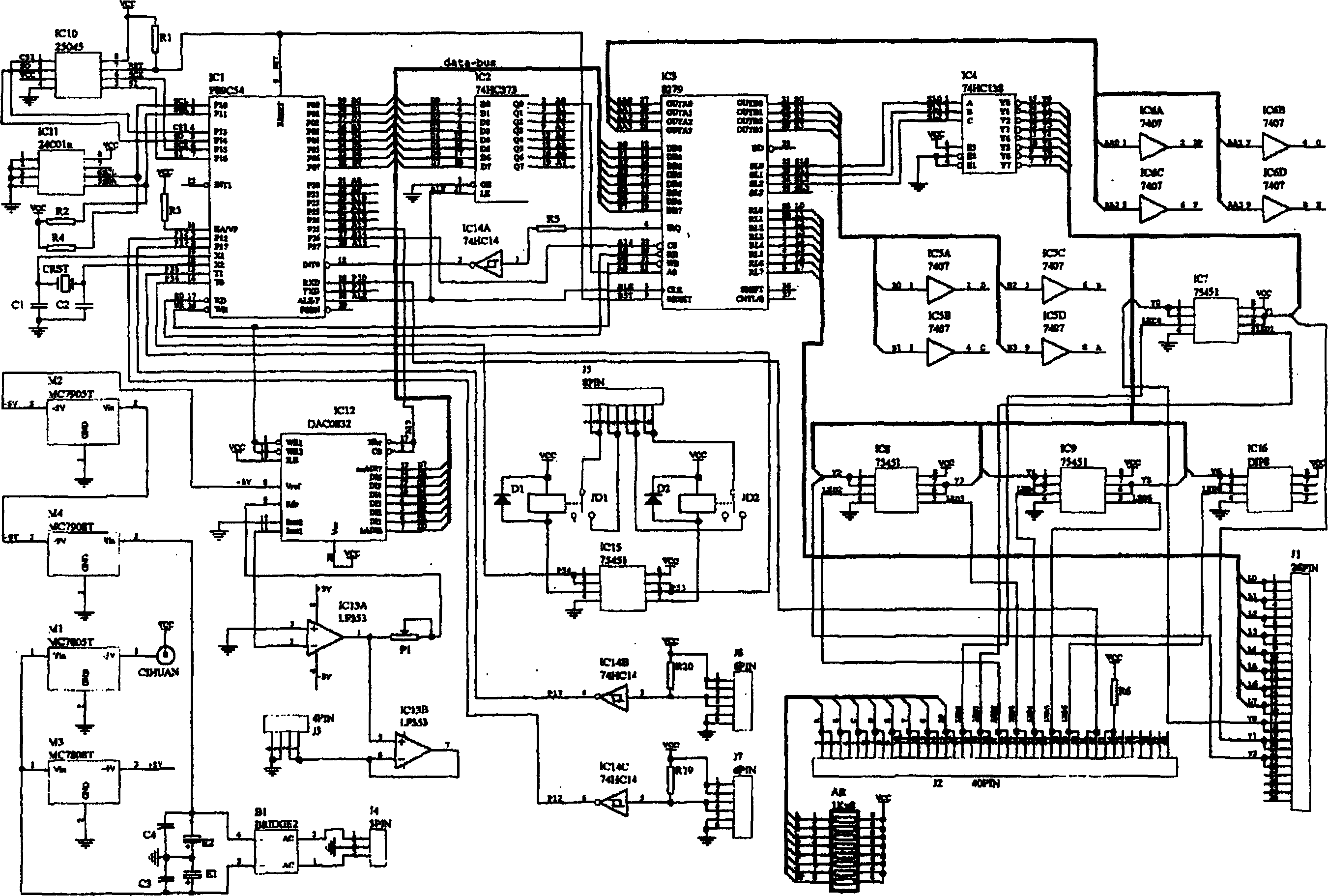

[0019] An important part of the present invention is the frequency converter, which can be replaced by a composite intelligent module A; the main control module is an 8-bit single-chip microcomputer; the liquid flow sensor is one, and the information of the liquid flow rate and the oil yield rate can be transmitted in a timely and accurate manner For the slave control CPU module; there is one rotary position sensor, which transmits the characteristic operating status of the pumping unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com