V-shaped belt speed transmission

A transmission and belt-type technology, applied in the direction of belts/chains/gears, transmission parts, connecting components, etc., can solve the problems of not getting enough supporting area, hindering the introduction of external air, and not being able to obtain machining accuracy, so as to improve the processability and productivity, alleviating pressure unevenness, and preventing dust and water from entering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Refer below Figure 1~5 An embodiment of the present invention is described.

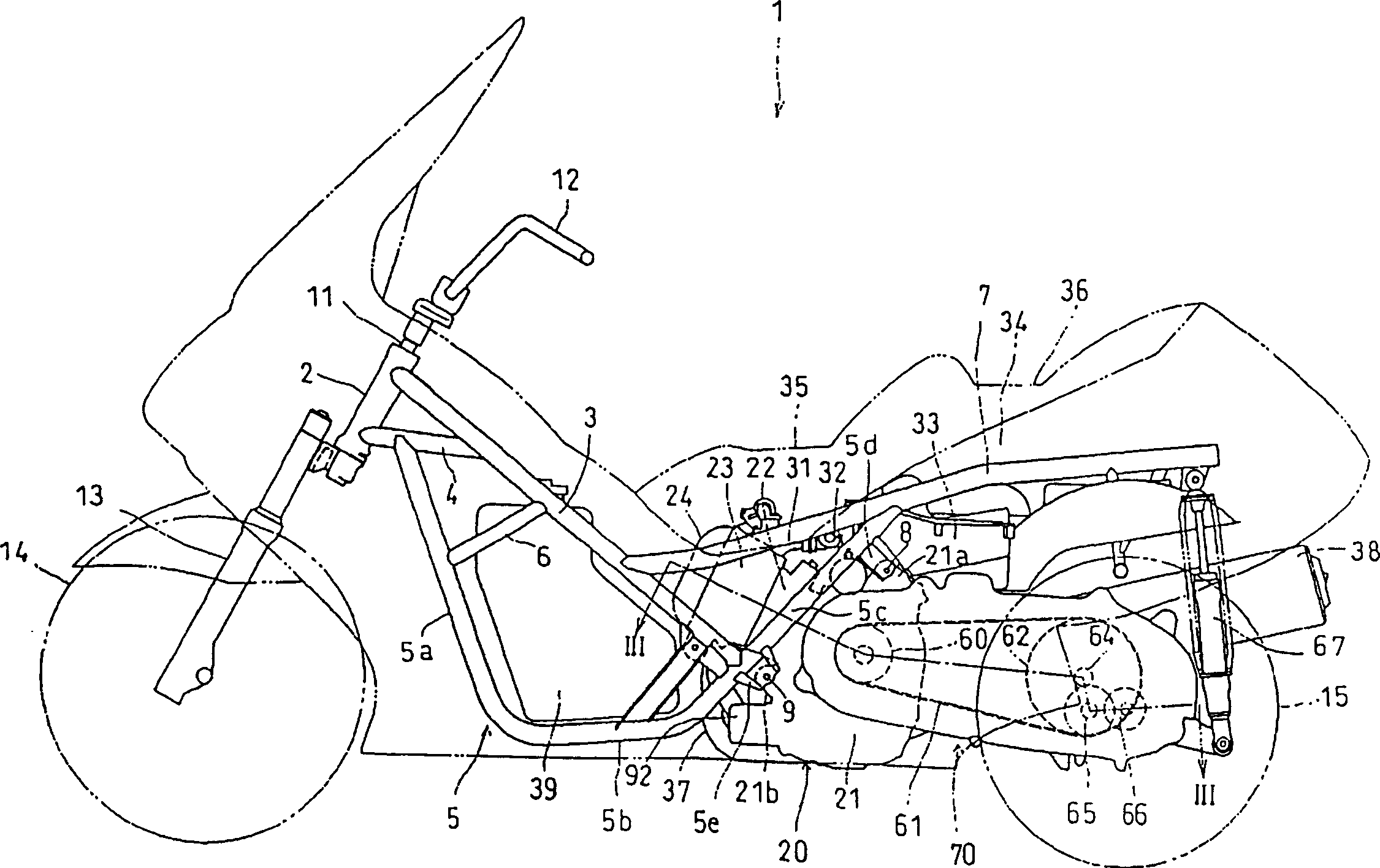

[0028] The internal combustion engine of this embodiment is suitable for a small two-wheeled motorcycle 1. The overall side view of the small two-wheeled motorcycle 1 is shown in figure 1 .

[0029] The frame of the scooter 1 has a structure in which a pair of left and right main pipes 3, 3 extend straight from the upper part of the head pipe 2 obliquely downward, as viewed from the side, and extend substantially horizontally to the rear from the head pipe 2 A pair of supporting pipes 4 and 4 are connected to the main pipes 3 and 3 and support the front parts of the main pipes 3 and 3.

[0030] Furthermore, a pair of left and right down pipes 5 and 5 extend from the middle part of the support pipes 4 and 4 to the left and right and extend downwards at a steeply inclined angle, forming the front vertical parts 5a and 5a, the lower ends of which are bent rearward. The rear ends of the central horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com